Ways to improve the service life of the vertical gear-reducing bearings

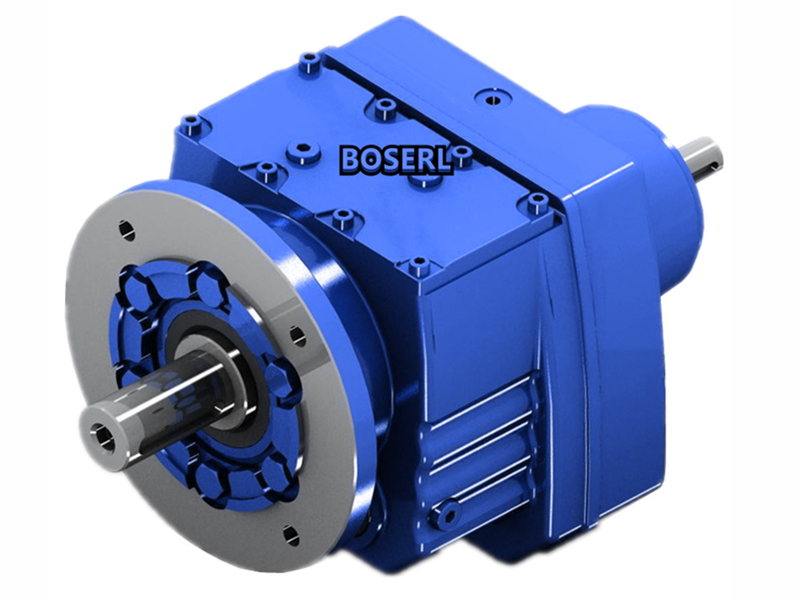

Ways of improving the service life of the poles of the flat gear-reducing power plant. In the design of the main structural parameters of the bearings, change the conventional design method of the bearings for the pursuit of large rated loads, reduce the rolling diameter and increase the number of rollers, while increasing the rolling pillar and pillar diameter to the progressive pillar and to maintain the overall strength of the frame, so that the rated load of the bearings may be slightly reduced, but this can be improved by a reduction in the rolling inertia of the scrolls, and by a corresponding increase in the circle wallMotor gearedThe impact resistance of the bearings is accompanied by an increase in the diameter of the pillar, which prolongs the lapse time of the shelf and the life of the bearings. In conjunction with the analysis of the causes of the failure of the reverse gear-reducing bearings, improvements have been made as follows: the use of a vertical gear-reducing bearings and roller materials for carbon seep steel 20Cr2Ni4 is selected for carbon seepage, and the surface is given a high hardness through surfaces, and the heart is softer, thus improving the resilience of the gear-reducing bearings. Gear-reducing power bearings have an equal life of six months, often in the form of fracturing and dewelding of the pillars. Standing gearsGeared motorThe lower operational life of the bearings is due to their special use conditions of high, heavy load and strong impact, and the absence of a corresponding lubrication, cooling system for the bearings, accompanied by a strong high frequency impact load。

Optimized design on the side where the frame and the roller side are designed to remain in contact, with an angle in which the inner and exterior sides are tilted, the benefits of doing so are twofold: to facilitate the entry of lubricant into the roller pillar, and to improve the support and roller pocket The second is to reduce the area of exposure to the side of the shelf and the roller, reduce friction heat and improve exposure properties, thus avoiding burns and glues caused by excessive friction. Rolling lanes and rolling surfaces, free from fatigue. CauseGear-retarding machineAnother reason for the early breakdown of the bearings is the welding of the sectoral pillars, the use of some of the company ' s productions to weld the external side of the gasket by smelting it to bind the end of the pillar, the low intensity of the welding, and the ease of welding in case of impact or shock loads. Because of the high rate of turn-off and poor lubrication and cooling conditions for the gear-reducing bearings, the bearings should be increased to the point where they are suitable, and because of the strong impact of the bearings, the bearings cannot be oversized. Motor geareds should also be improved in the welding process for the welding of welding gears, and welding should be enhanced in the form of an increase in the stairwell of the melting pond; At the same time, in order to avoid a concentration of stress, to abandon the screwdriver chute, to use a smaller transition to achieve a natural threaded tail, and to reduce the concentration of stress in the welding and screwdriver parts and tails of the pillars. The main reasons for the loss of the bearings are:Vertical reducerthe effect of the impact load during the operation of the bearings results in an instant reduction of the cortex rotation rate of the gear-reducing electric bearings and a subsequent reduction of the bearing roller rotation, while maintaining an instant impact between the support and the carrying roller with the non-carrying pillar, followed by a second impact with the maintenance pillar as the roller returns to normal, with a lower air power than the previous one, and thus the maintenance pillar remains under the cross-clip effect and is cut along the welding part and the tail of the thread. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Method for the service life of the power-reducing bearings