Axle-end retrofitting of snail snail snails with slash gears during the use of the wheel-crawler

An axle-end retrofitting programme is performed by a snail-reducing snail with slash gears during the use of the pyrotechnic. The inner end of the hollow axis is linked by a flower key to the wheel axis and conveys the twist. Re-engineered the link between the wheel axle and the snail reduction machine byMotor geared plus powerA 2 mm wide and 100 mm long process tank at the outer end of the output aerocentric axis without the end of the tank drilling the cracks, so that the high-heavy locks do not have to be too heavy to hold the hollow axle and the wheel axle to death, and to resolve the difficult topics of subsequent maintenance. The disadvantage is that the wheel is tilted, with an angle (8024 ' ) on the horizontal side, and welding is difficult to reposition; the increased quality of the re-purchased snail brakes themselves and of the welding substations will increase the quality of the left side of the arm and of the head of the arm as a whole and result in an imbalance between the right and right side of the arm and the overall subside of the machine. Fault analysis: spare parts have exceeded their useful life due to the long time of use of the equipment; maintenance and manipulation are irregular, such as damage to overloading protection levers due to the presence, resistance and impact of the shovels when the driver picks up the material; loss of acoustic wool grinding of the axle bearings, failure to perform sealing, damage to bearings caused by the entry of dust such as coal. The key mainly conveys the twister, with the retrofitting of the snail ' s output hollow axis and the wheel ' s axle, with the main charger, the slower and the liquid coincidentally self-heavy-induced bends, with the entire pre-modification headpiece hanging on the side of the arm. It's made up of motors, scalding machines, liquid coincidencers, and wheel axesBig load retarderThe output of a true hollow axis and a wheel axis is hung on the head of the arm by an increased set of links, and the extra-heavy rectangular overloading of the protection lever places it horizontally. In response to the widespread malfunctioning of equipment, in addition to the routine manipulation and enhanced maintenance of snails in day-to-day governance, there is a need for technical adaptation to make it easier to dismantle, shorten repair periods, minimize downtime and reduce losses。

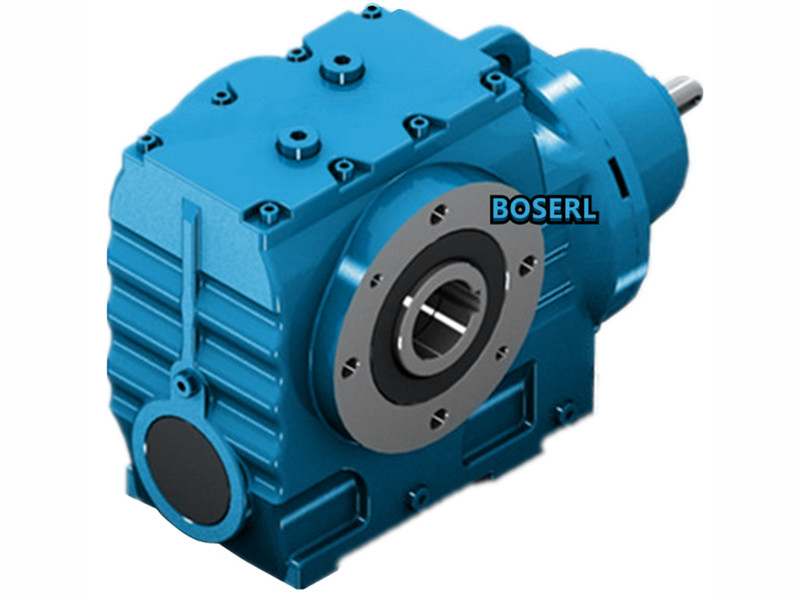

Option 1: Switching the output end of thereducing box to the wheeled axle from the previous upholstery to the flower key, as the key can only pass the rectangular, which is difficult to withstand with electrics, liquid coincidents, scalders, self-weighted bends, and welding on the side of the cock of the wheelHangerreducing powerAnd the power supports, and removes the force rectangles from here. A pyroscope is a trajectory handling machine that uses a continuous pyroscope and a continuous pyrotechnic stack. Option 2: The recalculation of the output end of thereducing machine and the link to the wheel axis is based on the previous retrofit-up link to both the bouquet and the retrofit. The advantage is that it will be very easy to both ensure the passage of the twist and dismantle. There is therefore a need for improvements in the rotor-driven head structure of the fighting engine. By contrast, we have opted for option 2, which addresses both the subject of moving and the subject of weighting of the entire predeterminator, so that the whole structure is both compact and easy to dismantle. A few years after the launch of a wheel-loader, there have been several major disruptions to the wheel-drive structure: the break of an overloading protection lever has led to the tearing of the carcass, damage to the axle bearings of the wheel, etc., because the wheel-axis and the cork-roller-out caving axle have been locked up and are more difficult to remove during repair, and, in the absence of a solution, the wheel-drill has to be cut off, the workload is high, the body is attached to the wheel-streaked arm, the body is condensed, the disassembled, and it takes a few days each time to break the wheel-dock, and the equipment is of high use, which seriously affects the company ' s performance。Geared motorthe output of a real hollow axis and a wheel axis are connected through an upholstery, passing the twists and bends by friction, which, after long-term use, cannot be removed because of the tightness of the glue. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The speed-reducing machine's at the wheel