Application of sledge snail brakes on sawmills

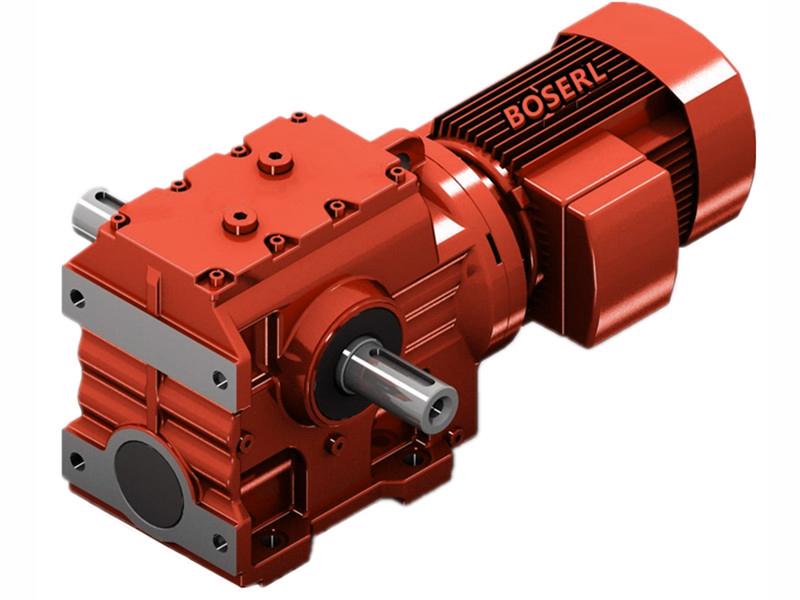

(c) The use of a snail-barrel brake on a sawmill. A small, dual-use saw-sawing machine with simple structure, small size, low power consumption, high efficiency and good quality. The main axis isThree-phase variant powerreducing machineIn snails, snails drive the snail wheel and re-rotate the ship. The outer section of the snail axle in areducing machine is a eccentric spectrometer, which is linked to the re-engineered spiral through a condensed axis and pole. It's good at cutting saws, but it's good at cutting saws. In order for the claw to be unobstructed by the steering board while working, a part of the back claw shall be reduced by one half of the thickness. If we want to increase the lift or drop of thereducing box, we move the contours to the outer side of the eccentric panel. When the decelerator drops, the relay pole is pulled back to position under the spring, while at the same time pulling back to the lower end of the arm and retreating back and pulling the claws out of the sawn teeth and stopping on the steering board. These movements are driven by a 0.000 watt power. Round saws vary in diameter, mobile axle arts workers, with different angles, unzip the argon screw, move on to the agular plate, and then tighten the acoustic screws once they have the right angle. The power is attached to a adjustable turret, which is driven by a beltMotoreducteurAnd fertilisers, grinding sawn teeth。

The rate of rise and drop of the snail snails is determined by the distance between the centre of the axis on the concourse axis and the centre of the snail axis. In order to reduce the weight of snailreducing machines and to improve the permeability of axle holesSnail scaldingAt its deepest point, the lubricant is only 7-8 mm, and the snails are 6-7 mm short of oil. For this purpose, a oil tanker with a diameter greater than the snail at one end of the snail, using high- rotation centrifugal power, is thrown a little bit of the oil on the snails of the decelerator to ensure lubrication. Both the front and the back claws of a saw are the result of the fact that a saw is often empty, and when one is unobservable, the other is able to draw another of the saws to ensure that they continue to move in. Structure: The sawmill has three basic actions: a high- rotation of the wheel to fertilise sawn teeth, a return to the wheel and a continuous passing of teeth. The action of the pull-out body is that the snailreducing machine moves the pole to the top and moves the arm to the left by pulling the axle and pushing the claw to the left. In addition to unloading the saw seat with all the parts on it, replacing it with a palette and an angular plate, as well as the parts on it, with a single claw and sander, the rest of which are not replaced, with some simple adjustments. The position of the relay pole is adjusted and fixed by the top thread below it. Because the scalding screws are secured on the stagger, they're driven by the retroverse of the eccentric spectroscopy, which causesPower-carrying brakesi'm not sure if i've ever seen anything like this before. the fertiliser drops to the limit of its position, adjusted by the repositioning screw, the nut, which is hung from the arm. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Use of speed-reducing machines on sawmills