Over-refuelling and tilting hazards of snail snail snails slashers

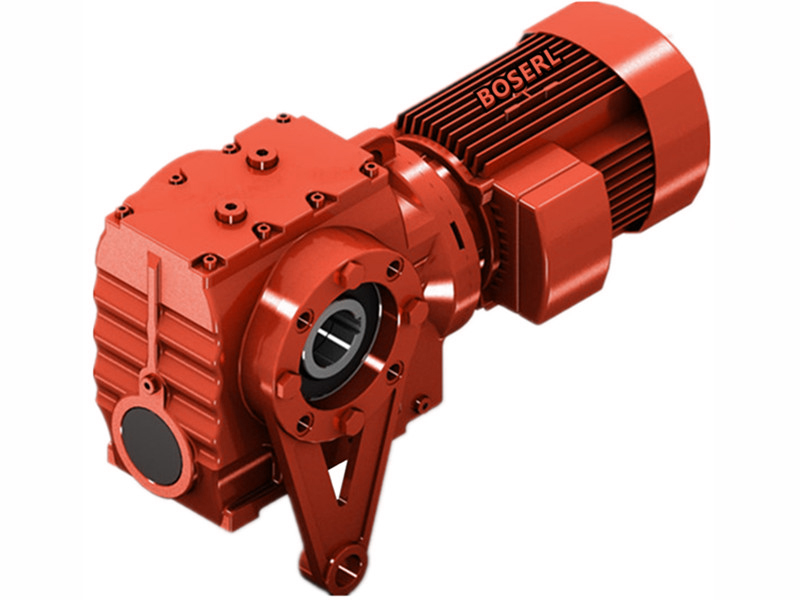

Over-refuelling and tilting hazards of snail snails with slashing gear. The direction of the hole is directed directly towards the tank, so that the excess oil can flow back to the tank through the tank and through the hole, in addition to increasing the ability to return oil by adding two pipes to the middle of the tank, connecting the pipe to the main pipeline, and placing the pipe vertically, increasing the pressure on the lubricants。Three-to-two-hundred-two-hundred-five-fiveDuring the installation process, if an alley is tilted and a lubricated tarpaulin is filled with the lower cavity of the box, the lower cavity is subject to increased local pressure and the seal is pressured in an uneven manner, which results in a widespread oil spill. The snail snail brake machine is to be tested strictly on the scale of the process. The quality of the assembly and the precision of the assembly are to be improved, carefully manipulated, without damage to any parts, and the installation of seals is to be observed. Measures to address: The oil spill caused by the tilt of thereducing machine as a result of its design, installation or ramping should be re-corrected or repositioned until the snailreducing machine is at a level consistent with the installation to address the issue of the spill caused by the tilt. In order to keep the excess oil from snail snails away from the axle seal, it is necessary to set up an oil reflow system, which can be used in the following ways:Gear with motorThe fast-axis cup is designed to be refilled with a refuelling tank in the middle of the lower end of the axle bearing, tilting in the direction of the interior, and opening the hole at the end of the snailreducing machine. The stains at the combined contact point are carefully cleaned and average coated with high-molecular seals, and the refuelling quantity does not exceed the scale。

YesGearbox motorOil spills in secret seals can be addressed effectively by new sealing materials, emergency surface patches using surface engineering techniques can compensate for oil spills in silent spots, and high-molecular seals can be used instead of general seals at points of exposure. The assembly shall be made in such a manner as to ensure that the position of the axle cover in the tank is reversed and the seal is damaged. Such a situation would also lead to accidents such as cavity burning axes and bearings. For better sealing, seals can be added to the surface of the two poles of thereducing machine, in combination with the body of its case, and also between the larvae and the end cover, with the two seals working simultaneously; In addition, the air vents of the scalders are often checked for smoothing, reducing pressure and pressure in the case to reduce oil spills; In the case of oil spills caused by poor refuelling of oil in the thick of winter oils and low levels of oil, heated pipes could be added to the bottom of the tank to reduce oil spills by progressive oil temperature. Check if the oil seals are retrofitted, if the stop is damaged, if the external valves are deformed and if the springs are solid. Welding is strictly as required and strong as required, Frank, and welding is as required. Lubricating oil is the basis for ensuring the proper operation of the equipment, butElectric brakesthe oil from snail snails can be deposited in axle seals, concourses, etc., if the motor is overfueled, thus also causing a spill. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Overcharged refuelling and tilted hazards on speed-reducing machines