How can gear-reducing machines be maintained in a high-intensity working environment?

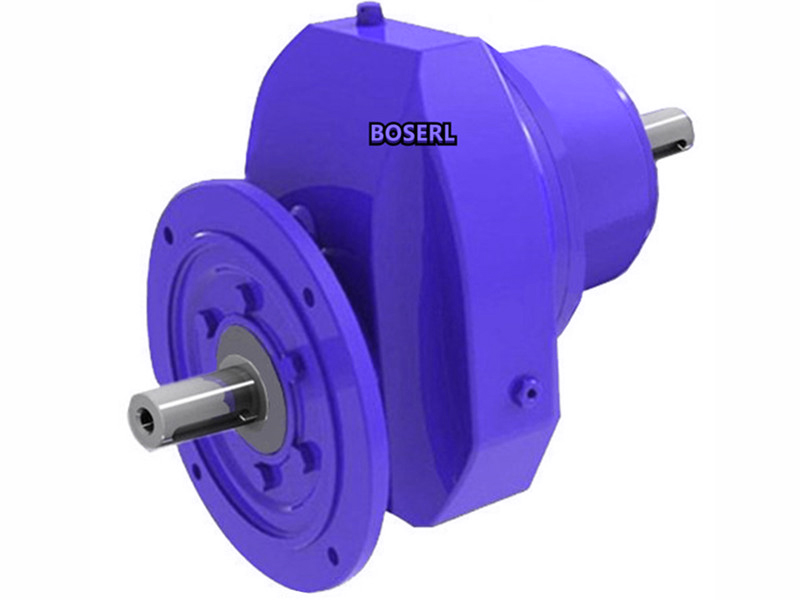

How can gear-reducing machines be maintained in a high-intensity working environment? In the use of brakes, demand for them is becoming increasingly demanding due to changing demand for them. Without proper maintenance and selection of the right size, the working life of the gear-reducing machine will be significantly shorter than expected, regardless of the gear-reducing device design. And the transmission power when the slasher operates is driven by a condensation between the two slashed gears, which, on the other hand, also shows a low rate of transmission efficiency. Transmitters that run 24 hours a day depend onGear motorsAnd thereducing machine converts and twist to motion. Therefore, during the installation process, it is necessary to ensure that the gear-reducing machines are closely connected to the gear-reducing machines and that no gravitational knocks are used during the installation process, which would otherwise affect the bearings or damage to the axes. Some users will linkreducing machines to other devices to testreducing machines for shock or for a variety of faulty topics. On the other hand, because the installation was not robust, the gear-reducing or gear-reducing machines were constantly diverted from their original position at the time of operation because of the shock they generated. At this point in time, it is important to keep in mind, in the course of the operation, whether or not the internal gear structure of the cone gear-reducing machine is capable of carrying out such a high intensity and long-term operation. Lack of lubrication can lead to premature failure of the gear-reducing motor transmission group. If you have problems withreducing machines or gear-reducing machines, or if you have maintenance problems, you can be consulted with b0serl-reducing technicians. let's look at some of the detailsDouble- power deceleratorThere are some minor differences in structure design, so there are different maintenance strategies for differentreducing machines. So how do we maintain thereducing machine or the gear-reducing machine?

The repair of the brakes at a later stage due to the failure of maintenance would have resulted in significant capital costs, including the use of the shutdown and the level of repair. There are several different series of gear-reducing machines, such as gear-reducing machines, cone gear-reducing machines and turbo-slash gear-reducing machines. YesMotor gearedThe physical wear and tear in such a situation is accelerated for reasons of inadequate material in the internal gears, which causes a wide range of malfunctions. Companies usually decide to maintain the wrong equipment for any type of maintenance in order to save money and time. Many of the larger initiatives have hundreds or even thousands of gear-retarders andretarders in operation, and do not have enough maintenance technicians to carry out the required fuel. The savings are only short-term. At the time of design, some adjustments were made to the gearing line of the gear, which resulted in four series of gear reduction machines having less noise and operating efficiently and calmly. The need to select the exact type when areducing machine is in use is of primary importance, because when a model crosses the title, it is easy to draw up the title, as if it was not strong or was of too large size. It is believed that the market needs to be accommodated, and ourreducing machines are constantly being adapted to meet the conditions in which the various devices are used. In addition, gear-retarded electric power temperature, ambient temperature, electric current intensity and the electron brain frequency can be tested in all weather conditions throughout the year. Some large-scale equipment, such as a few gearboxes, may sometimes take a long time to run, such as eight gearboxes on one device operating 24 hours a day for up to six days. So what should we be looking atGeared motoror the electrical process. gear-reducing machines are a component of the hubs that are individually manipulated. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: How speed-reducing machines are maintained in high-intensity work environments