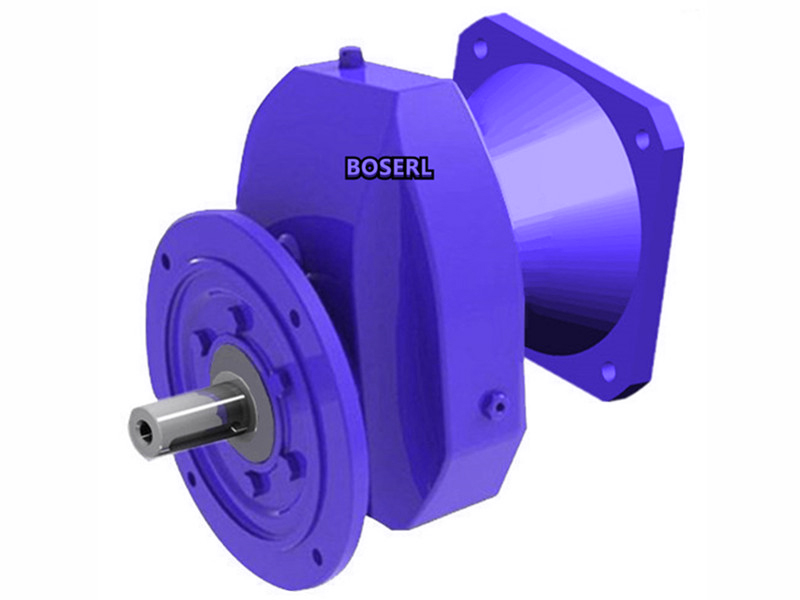

B0serl gear reduction motors environmental efficiency standard

B0serl gear reduction motor energy efficiency standard. This is due to the fact that, with the sensor power, the stationary current sector, the wheat-induced rotor current, produces transmagnetics. the loss reduction is the long-range magnetic-sync series b0serl, which is an environmentally friendly electrical rangeRight-angle shaft reducer motorAn efficient rotor design has been used to integrate embedded ultimatums made of rare soil, instead of rat cages that turn to the discovery of traditional sensory electrons. Compared, in two electric power plants, electric disk-based enrichment units are used daily [hours]. For the users of the emso, this improved electromechanical power is sufficient for ie4 energy efficiency measures, such as b0serl's scope of the emsoe, which is usually a permanent magnet line and maintains its own continuous magnetic field. To confirm this, so far we have seen improved technology and efficiency translate into higher initial purchase capital, which is later recovered from the service life of the permanent magnetic synchronized electric power. In this case, it was also discovered that the operating capital of an e4 generator would have been significantly reduced if the initial purchase had been made. b0serlMotor geared plus powerThe control scope of the motor is already adequate for the classification of the upcoming requirement ie4 (super-efficient). The results showed that pmas delivered 40 per cent of the energy consumption and asm, of which 1022 kilowatt-hours (kwh) would be saved when the projection took four years. While it is well known that 70 per cent of the energy-capable capricorns are used, it is a little known fact that 96 per cent of the life-long electricity is associated with energy consumption. This shows an overall efficiency ratio, and the initial importance is to buy the money under the terms of the total ownership' (tc0). Many processes in the water treatment industry need to be continuously manipulated and loads may change with changes. Energy prices are expected to rise, so it is important to be perceived as running capital for life, not simple capital. Nada, a large number of electric generators in this sub-saharan region, could benefit from thousands of new electricity and technology. "。

This is proof of their potential to achieve up to 40 per cent energy-saving borby, 2-reverse squirrel-activated squirming. The ESP series is an environmentally friendly electric range, and the introduction of efficient rotor design offers some hub benefits. The test is to use the same frequency transformers and gear transformers to ensure that any efficiency difference can only be swallowed by an electric generator. Besides, hard-noodledGeared motorThe EMS drive can produce a higher volume of twirl and conventional induction headlamps, which tend to promise book-to-book money, with a smaller power size specified for the village. Such a design provides for a few hubs “which reduces the loss of rotors by 100 per cent. The total loss of irradiation is about 25 per cent, with more than 10 per cent of the total efficiency of cotton and more than 10 per cent of the pyrotechnics and saplings, which translates into lower total ownership to reduce C0'2 emissions and sustains the spring and the increase in the future energy production of the crocodiles.” Of these strengths, it is worth noting that, in comparison with the sensor electrons, efficiency progress is premised on a very high level of efficiency, subject to sectoral affordability. As energy prices appear to be rising, so the value of this savings will increase. It reduces the heat loss by 100 per cent from rotors and a total loss of about 25 per cent, and more than 10 per cent of the total productivity of the stainless steel drive is significantly less efficient than aluminium or cast iron dispersion. These are more expensive manufactures, but they are significantly stronger than the scale magnet. In today ' s market, energy efficiency must be the determining factor in the designation of new power solutions at the hub. PMSMs also have a proportionately high power density, which results in higher system efficiency and smaller installed sizes - as well as reduced weight for gear-reducing machines. This higher power density promised the development of long-magnetic synchronous electrons in low inertia and could provide a faster response. When the electric power is used, the reverse engine usually requires a power generator, but the efficiency is close to 96 per cent. However, in an EMP, the rotor magnet is a permanent magnet that has been set up. These additional currents produce hot stars in the electric power. To confirm that, B0SERLMotor gearedThe Department intends to participate in the same tasks as the Direct Relative Transverse Atrotrocers and the Invalid Magnetic Synchronizer (ASM). http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Environmental efficiency standards for gear reduction motors