Weight of gear-retarder transmissions

The weight of the gear-reducing machine transmission device. The role of carbon seep in the wrinkled strength of the rotor, in addition to making progress in the hardness of the heart, is also associated with a surface residual pressure, which can reduce the stress of the rote pull zone. In general it's more than the weight of the gear, andGear-retarding machineThe weight is strongly related to its material and thermal processing hardness. Thermal treatment methods for obtaining hard tooth gears, such as surface acne, whole acne, carbon acne, nitrogen accelerator, etc., should be considered in the light of the characteristics of the gear agility. For example, at the same power, the weight of the permeable pyrotechnic gear will be approximately one third of the weight of the molar. The hard layer of the surface acreage is good when it includes the base of the teeth. 3 - Nitrogen seepage ensures that the gear reaches high in small deformationsGear motorsFace hardness and millability, which can no longer be processed after heat treatment, have improved carrying capacity。

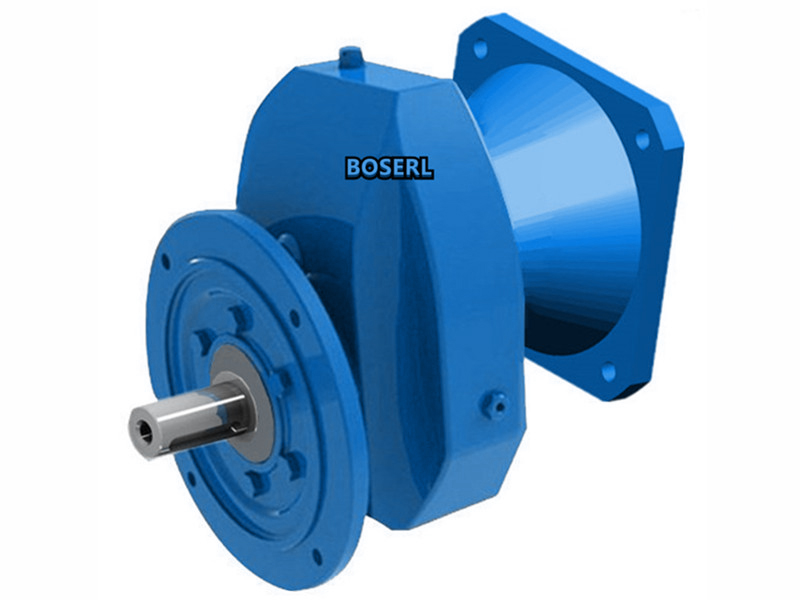

Therefore, the dentures cannot be worn in the root sector and the dentures must be used for the roller. 2. Carbon seepageMotor gearedWith relatively large carrying capacity, it is necessary to eliminate thermal process deformation by using a process process (branding) to ensure accuracy. When both rounds are hard-love and higher, the same hardness is taken. The hardness of the caustic pyrotechnic gears should be gradually reduced from the top to the bottom of the gear, while the depth of effective seepage should be progressively reduced from the surface to the deep, and the depth of effective seepage should be defined from the surface to the depth of 52. 5 hrc. Materials commonly used for surface pyrotechnics are about 0. 35 per cent ~0. 5 per cent of the carbon mass of steel and 45-55/hrcs of teeth. This is of particular significance for inner gears, which are not susceptible to grinding. Carbon seepage pyrotechnic gears typically have a mass score of 0. 2 ~0. 3 per cent of pre-carbon seepage alloy steel, often within 58 ~62 hrc. When below 57 hrc, the tooth strength decreased significantly, and was greater than 62 hrc. The selected gear-reducing machine materials facilitate the carrying and operational life of the progressive gear-reducing machine. 1. The two methods of surface gill fire common to surface gill fire are high-frequency gill fire (for small size gear) and flame gill fire (for large size gear). The rotor heart is so hard that 310-330hbw is appropriate. 4. The hardness of the rodents shall be higher than that of the big gear when they are both large and small. so for the gearGeared motorthe structural characteristics of the gear and the load nature of the gear should be widely used. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Weight of gear-retarder transmissions