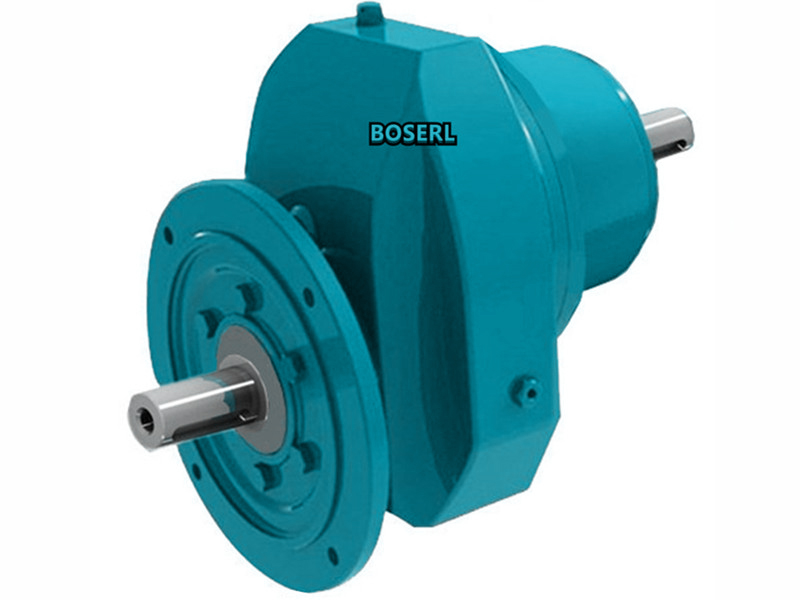

The gear-reducing machine is an independent, closed transmission between the motor and the work machine

The gear reduction machine is an independent, closed transmission between the electric motor and the work machine. It is widely used for the repair of mechanical wear, scratches, pits, cracks, leaks, sand-eyes, etc. of metal equipment, as well as for the chemical preservation and restoration of various chemical storage tanks, reaction tanks, pipes, etc. The above is the role of a simple pre-emission-reducing oil seal, which is understood in other ways. YesSpiral cone gear deceleratorAt the time of selection, the quality of the seal and its construction are the type of decelerator that must be understood. In the case of oil spills at the Silicon Seal Point in the operation of thereducing machine, a surface remedial implacable, which can be used for surface engineering, is adhesive, thus eliminating the spill. In the case of leaks in the slant-barrel vessel, leaks can be managed on site using Micahite Molecular Composites and Technology, without being removed, high-molecular Composites are leaking outside management, save time and effort, blow rice, its products have a strong sticky investment, oil resistance and a 350 per cent stretch, overcoming the impact of the slowdownr vibrations, and solving for the enterprise topics that have been unresolved for many years. It is an important component of the machinery for coal mining, which is used to reduce the rate of rotation and increase the rectangulars accordingly. 3. Thereducing caps are randomly manipulated and are not familiar with the risk of oil spills from thereducing machineGearbocThe structure was well designed and resulted in a general oil spill. 2. The second reason may be that the lack of proper design of the slowing machine causes oil spills from the gear-reducing machine, such as when a type-reducing machine is designed without a wind mask, thereducing machine cannot achieve average pressure, resulting in increased pressure in the case, which can then spread。

Motor gearedHigh-molecular composite material is used for the management of oil leaks from the reduction machine, which is based on high-molecular polymers, metal or ceramic super fine powders, fibres, etc., and is composited by solidification agents, solidification promotions, etc. The various materials add-ons to each other ' s functions and create synergies that enable composites to function better than the original composition. In actual output, the mine-slashed gear-reducing machines easily spread to varying degrees of oil spills due to the poor working environment, heavy loads and frequent operation of equipment, which not only contribute to the spread of energy, contamination of the environment, but also to the lack of lubricating oil in the case, which leads to a fever of axle bearings, drying, glitters, point erosion, etc., which ultimately reduces the working life of the slow-reducing machine, which in severe cases can lead to an equipment accident, a huge amount of heat to be delivered in the closed space of thereducing machine, and each of the gear-releases in the gear-reducing machines will collide, which, with the increasing number of working hours, will lead to a gradual increase in temperature in thereducing container, while the internal accumulation of thereducing container is fixedElectric brakesinternal pressure will increase, while the oils inside thereducing tank will be more permeable, so where the seals are not tight, the oils will permeate from where. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The gear brakes are electric motors and work machines