How to handle gear-retarding

How to respond easily to the loss of gear-reducing axes. Some users, when choosing the type, mistakenly think that they can do as long as the rated output of the slanted gear reduction machine that they choose is a twirling jobGear with motor, the value obtained is in principle less than the Quantification Quantification Quantification Twirl provided by the product sample, and the second is to take into account the excess capacity of its driver as well as the large-scale working twist required in practice. The selected materials are high-quality carbon-structured and alloyed steel and are not sufficiently functional and robust without effective heat treatment. It must be less than twice its rated output twist. Selective or material defects result in the wrong selection resulting in inadequate capacity of the machine. In particular, there are applications where strict compliance is required, not only to protect the machine, but also, and above all, to avoidFlow-reducing electric powerThe output axis is broken。

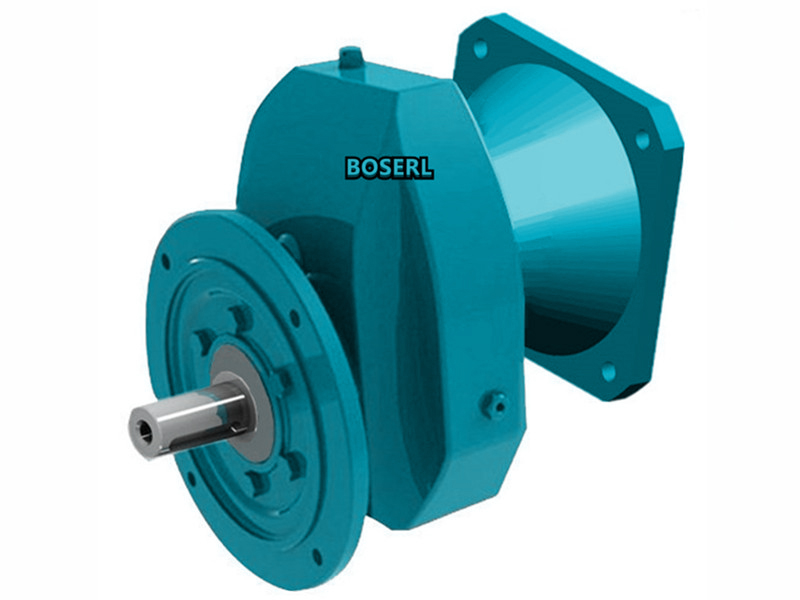

If there are features in the installation of the equipment, the electric axle is often designed and crafted with a variety of troughs (e.g., troughs, unloading tanks, etc.), ferries and axle shoulder structures, and if the trough structure is unfair or uneven, the transition angle is too small and the axle is more variableMotor gearedThe output axes and their loads are stuck, while the overload capacity of the motors will continue to increase their capacity, and the stress distribution of these parts will be extremely uneven, resulting in microbracking and expansion in areas with particularly high stress, which will then lead to a break-up of the flaring. Thereducing axis will eventually be cut off if it is more than twice as fast as its rated output twist and the acceleration and deceleration is too frequent. reducer energy is converted to mechanical energy, and in the process of energy conversion, the equipment is operated by the installation of a wheel or joint axis on the output axle, with the transfer of the rectangular through a belt or joint axis. Except becauseGeared motorthe output end is not well equipped with a concentricity. if the output axis is broken, the electrical axis breaks on the side of the load, which may mainly extend to the front bearing, where there are significant knife marks, where the ribs are combined with the main axis, where the axis shoulder and the tank are present. based on the analysis of the test studies, the following points can easily be addressed on the subject of break-axis. theoretically, users need to work hard. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Question of gear-retardation