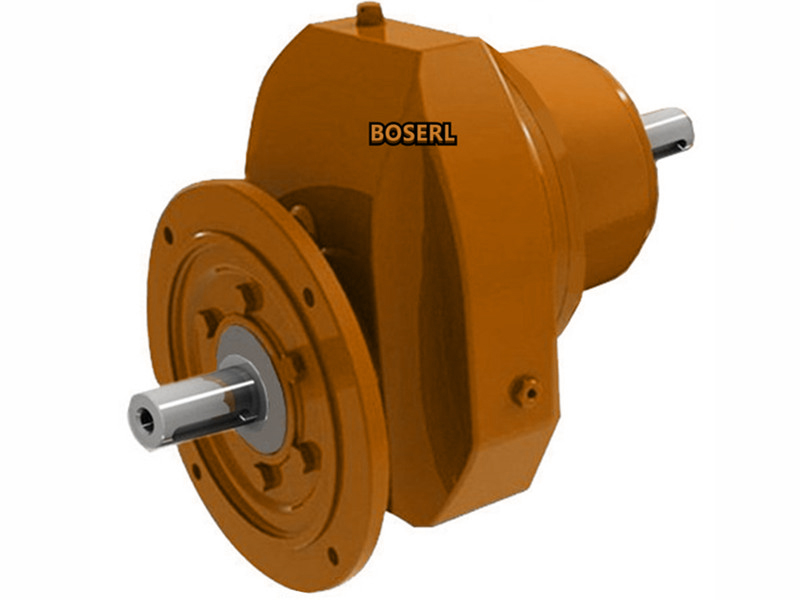

Axle oscillating gear reduction engine master reduced to total assembly line

The main axle gear decelerator is reduced to a total assembly line. Large, high-precision and reliable work can significantly improve output and assembly quality. The detailed deployment process of the gear-reducing motor was then described for the total assembly line. By comparing the advantages and disadvantages of the various types of car assembly line set up, we have provided us with a theoretical guide for designing other car assembly line. YeahZip gear brakesThe advantages and disadvantages of each major assembly line are compared. The design to be considered for the deployment of the gear-reducing power units in the main assembly lines is simple and prefaced. A comparison of the advantages and disadvantages of synchronous and non-synchronous flexible assembly lines resulted in non-synchronous flexible assembly lines that are better suited to the total assembly lines of the gear-reducing machines. In order to change this situation completely, the gear-reducing power plant assembly line has a special measuring capacity, using a working control machine to control a special metering machine, the online loading of analog assembly and simulation of the data, and the computer processing and statistical analysis of the gear-reducing machine, which displays and selects the adjustment pads to ensure the quality of the assembly and to reduce the re-engineering until it is replaced. We use a dedicated pressurizer with a down-cylinder, which is the same as the upper- and down-cylinder pressure, so that we can ensure that the pressure is done onlineMotor gearedDeformation can also be avoided by pressure on cars and assembly liners。

Structural analysis and a fair-span process are required for the placement of the main assembly assembly lines of the axle slash gears. Through the LordSecond-stage brakesThe total structure is analysed, the assembly process, the main equipment and the tools for the fair laying of the assembly line for a variety of products, and the installation of the main assembly line in terms of the overall assembly process for the main deceleration. For this purpose, the assembly line is reinforced by a electrodynamic wrinkler, which is controlled by a computer closed ring, not only by a smooth, large and high-precision rotation, but also by being able to show in real time the actual wrinkles and high-stringings at the time of the rotation, with the sector wrinkler being able to perform phase control according to the needs of the gear-reducing power. The pelvis bolts for gear-reducing motor masters and the bolts of the left and right shell bolts, which are automatically controlled by the working control, removes inter-axis inter-axis inter-axis twirling at multiple axle-wrestling, and ensures that the axes meet the set twirling values and a fair-way inter-axis。

The hub for the total assembly mass of the main braker for the coaxial tilt gear is the exact acquisition of the appropriate bearing pre-heavy rectangular and the precise contortion of the main bearing, from the moving gear, depending on the accuracy of the thickness of the pre-heavy rectangular adjustment gasket and the geared adjustment pad, respectively, which the assembler has been able to select with experience and subject to the subjective selection of the gasket to easily create a gap and retortion of the assembly. The following conclusions were reached: coaxial slash gearGeared motorRemodelling and PLC control, based on mature products from a formal manufacturer, are based on detailed requirements for individual compacting positions, so as to be both aware of the pressure load requirements and to ensure that the gear-reducing pressurizer is of high quality, reliable and robust. Large screws at the edges of the gear-reducing motors, with high swings and high requirements for twitching values, as well as for sector products. The axle gear reduction machine also has a special tool for the detection of the actual thickness of the gasket to eliminate the effects of the nominal size error of the gasket. The main equipment structural features and functions of the main assembly line are first incorporated. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Reduction in the overall assembly line for the slow down engine