Accuracy design for the main axis of the parasol gears

Precision design of the main axle of the turbo. If it is too bad, the key will not be loaded into the key slot, or the key and the key slot will not ensure sufficient contact to pass the twist, so the symmetrical mass is gb/t1184-1996, which takes 7-9. The inclusion requirement is used here to ensure its complementarity. the size of the neck of the axle is the same as that of the bearing, the accuracy of which is related to the accuracy of the bearing, and, in the case of the bearing, the normal poGear motorsIn view of the rotation load and light load of the inner bearings of the gear-reducing motor at this position, it has been determined that a small excess is to be applied and that the basic deviations are to be used.j This leads to a deviation in the scale code for j6. The following is to be determined: +0.012 mm, lower deviation: -0.007. In order to ensure the accurate positioning of the paralysing vessel so as to be capable of receiving a load average, two-axis shoulders have been assigned to an end-turning requirement with a value of 0.015 mm relative to the base axial line A-B. The roughness of the surface is based on the roughness of the GB/275-1993 c-axis neck and the outer hull hole to match the surface. Umbrella gearsGeared motorAxes ' accuracy design process: Depending on the type of transport, the axle ' s accuracy design can be divided into size, shape, range, surface roughness, etc. The size of the key slot is the same: the size of the profile of the GB/T1095-2003x key slots, defined by the sizes of the GB/T1095- 2003x key slots, which are connected with normal connections, and the actual central level of the position of the key slots is the symmetrical of the actual central level of the main pointer of the axis of the base。

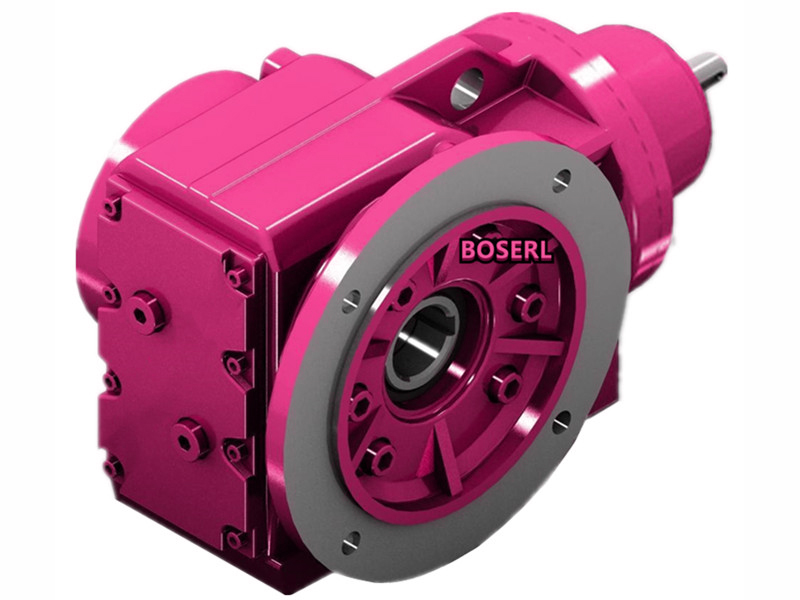

The precision design of the turbo is a very important and complex design element, requiring the design staff to have substantial practical experienceBig load retarderThe motion axis in it is designed to be complete precision and streamlined at a defined level of length, without prejudice to the reflection of overall design. This paper is analysed and designed according to the different co-ordinated parts of the axis. The roughness of the surface of the axle neck: its size directly influences the matching nature and intensity of the connection, and therefore the high roughness of the bearings and the outer crust of the corrosive bearings of the gear-reducing engine and of the outer rims, which is based on the roughness of the surface of the GB/275-1993 medium c-axis neck and the outer hull hole, can be determined to be 0.8 um. Based on this analysis, the bearing is a thin wall, which is fitted with an axle neck and shell hole to correct it, so that the outer shape of the collar is closely related to the outer surface of the axle neck and of the outer shell, and a cylindrical deviation requirement should be applied to the axle neck of the gear-reducing machine and to the surface of the outer shell, as determined by the scale, corresponding to the PO bearing, which is 50-80 mm in basic dimensions, and the cylindrical mass margin of 0.005 mm. The cylindrical bearing of the neck is combined with the two holes in the frame gear-reducing machine, taking into account the proficientity of the error detection, and therefore the two-axe neck-to-pectoral ejection public difference of 0.025 mm. is a wide range of parts to be applied in mechanical equipment, which is primarily used in the gear-reducing machine to support the gear and to transmit power and load, and therefore has an important status in the umbrella-revation machine. Principles of travel on axle neck:An umbrella gear-reducing machineaccompanying, which is important. the current mechanical design contains only a specific description of the axle ' s structural design and strength core, while the precision design is rarely described, resulting in students ignoring the importance of precision design. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Accuracy design for the main axle of the slowing machine