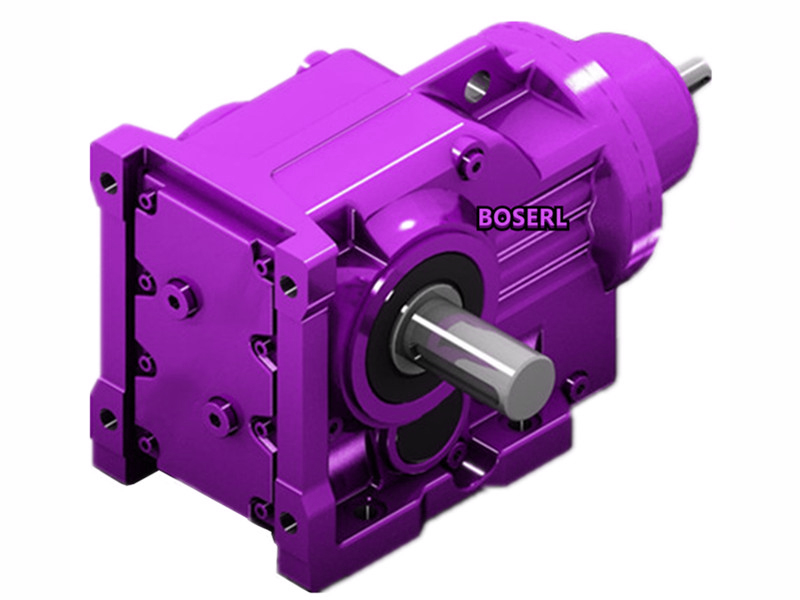

Spiral cone gear reduction machine cleanness test

Test of the cleaning of the propeller gears. That is, the method of measuring the cleaning of the gear-reducing power plant by the weight of the stains collected in the machine. And then I'll..Motor gearedThe cleaning fluid in the machine, together with the sludge, is placed in a clean metal drum through the oil hole until the wall is washed clean in the machine. The low- heavy-carrying wheel gear-reducing machine with a small oil membrane thickness of 0.03-0.07 mm between the teeth, for this purpose, takes into account that in the gear-reducing motor, filtration large particles do not affect the formation of small oil membrane thickness in the teeth, but are filtrate. Each part of the machine is then repeatedly cleaned with a brush or a brush. The formula for the cleaning of the propeller gear: the deviation of the cleanness promise is the sum of the total central distance between the parameters when filtering the net with 200 inches and the total central distance of the gearer. The indicator determines how much oil is stored in the oil tank of the propellers ' gear-reducing gears, in line with the linear size of the total central distance of the brakes. Method of detection: 200-eyed/in-inch metallic sifter is immersed in a cleaning fluid (carine) for five minutes to be pumped into a oven with a temperature of about 120°C for 30 minutes, before being cooled in a dry tank for 20-30 minutes until the laboratory is warm. In the previous chapter, where we had a first-hand review of the maintenance and maintenance of a screwdriver gear-reducing machine, we described briefly the following:Right-angle shaft reducer motorQuestion of cleanliness。

The finished parts are gradually carried out outside the body of the machine in accordance with the assembly procedure, in a clean container and then in a washing machine. The sift is weighed with the stains in the scales, so that it is well documented. The sift is then weighed on the analytical scales with a fraction of precision, and values are read and recorded. Considering the current situationSpiral cone gear deceleratorThe size of production at the manufacturing plant and the process premise that, without prejudice to the safe formation and use of the intercombrand oil membrane, the weight of the stains should not be greater than the share of the total lubricant weight in the oil tank, but, since the amount of oil in the gear-reducing engine lubricating oil is refuelled on the basis of the height of the oil surface of the oil measuring unit, the overall central distance of thereducing machine is used to determine the cleanness indicator for the purpose of calculating profit. Therefore, the use of 200-min/in as a swirl gear-reducing cleaner filter will then be an indicator of control. Opens the hood of the gear-reducing machine, places it in the cleaning fluid, the amount of which is added to the oil surface of the wheel-reducing gear. The weighting method is used for gear-reducing machines that block all splattered oil tanks. The brushes, brushes, etc. used in cleaning must also be washed in a barrel if the stains are adhesive. Cleaning liquids and sludges in drums are filtered with a 200-point/in-inch metal screen. At present, there are two methods to detect internal cleaning: the particle method and the weighing method. And the proportion of the total amount of oil in the tank is considered to be the weightGeared motorthe indicator of cleanliness is more appropriate. the stains collected in the sift will be dried again with the sift after volatilization, and then cooled at the same temperature and time as the first. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Testing of speed-reducing machine cleaning