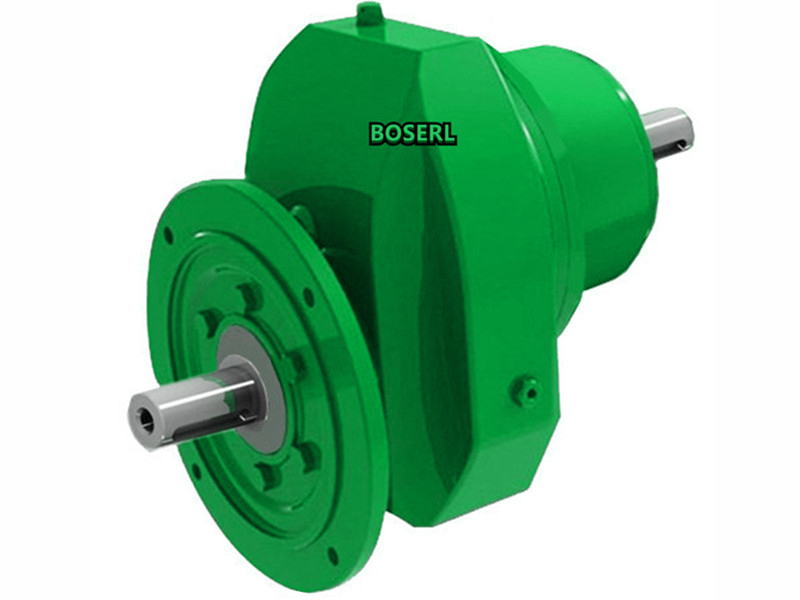

Structural improvements to the oil spill from the recoiler 's gas caps in the gears

(c) Structural improvements to the oil spills from the vehicle gas caps in the recoiler. Following the completion of the new structure, which inherited a test observation, adding a third of the normal value to the lubricant, the rectangular gear-reducing power plant was operating for three hours, without a general gas cap spill. Thus, while the vehicle ' s motor lubricants are low and do not spill through gas caps, the potential risk is much higher than the appropriate excess refuelling. The spills of this lubricant and the reverse of the carving power, the viscosity of the lubricant, andDouble- power deceleratorOperating time is related to factors such as non-discrimination. Following the completion of the upgrade, the test was carried out, the lubricants were added to the normal level and were operating in reverse and in a three-hour period, without a general spill. In order to avoid the loss of gear and axle bearings as a result of too little refuelling, users, with an appropriate amount of refuelling, are still able to avoid oil spills from the jet caps and to reduce the and flow of the oil flow by adding an oil shield to the original structure, commensurate with the creation of two dams to prevent the flow of oil. The risk of oil spills from gas caps and seals is increased by the appropriate excess of fuel, the loss of oil-polluting energy from gears inside the gears and the reduction of the efficiency of the gears, but not by the severe consequences of the loss of gears and bearings。

In order to fully address the issue of oil spills from gas caps, to simulate whether the use by users of the field to add more than one third of the normal value of lubricating oil to the oil spill, to carry more lubricant oil, to carry on with the test, to extend the operation time, and to gradually spread the gas cap spills, for reasons analysed: the gears used when the gears slowed down the motors were operating because of the increased immersion depth of the oil, the currents of the oils dumped with the lubricant oil, and the currents of the oilTurn frequency brakes slowing downThe impact of internal collisions has also exacerbated the spilling of lubricating oil, at a time when the entire oil flow could no longer be blocked from the oil sheet. However, oil spills often occur in the respirator ' s air caps, and this is more difficult to avoid. In order to identify the real causes of the oil spills from the air caps, a specific retrofit was made for a nightgown gear-reducing power plant, which was designed to be placed on the optic lid on the top of the gear-regulating machine. For ease of observation, the optic lids on the hoods of the turbostats were changed to organic glass。

A rectangular retrenchment is designed at a higher part of the relative oil. The function is to maintain the external pressure balance within the gear retrenchment and to maintain the rectangular gearGeared motorNames are sealed well. After identifying the reasons, the original gas cap structure was adjusted so as not to allow the current to be dumped on the cap, increasing the height between the eye cap and the lower shield, while increasing the length and width of the shield, which is intended to allow the oil flow that is thrown above the plate to be inhospitable, to be able to flow at any time, to prevent the current from reaching the upper part of the gear-reducing electric vent, and to make it impossible to spread through the gas cap, and to increase the length and width of the shield to reduce the likelihood that oil currents on the gear-disposed are splattered. Considering that excess refuelling in use by the actual user cannot be entirely avoided, and that small refuelling would result in poor lubrication of gears and bearings, affect gears and bearing life, cause the end-of-life of gears and bearings in times of severe severity, and that, in the course of use, users may often view and update oil. The gear-reducing power plant is functioning at a normal time, as the gear is rolling at a high, and the gears continue to dump lubricating oil in the form of oil currents into the oil shield under the eyebrow, increasing the spill through the vent. I haven't seen anything since the rectification of the turboZip gear reductionoil spills during the use of air caps. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Structural improvements to oil spills from power-reducing air caps