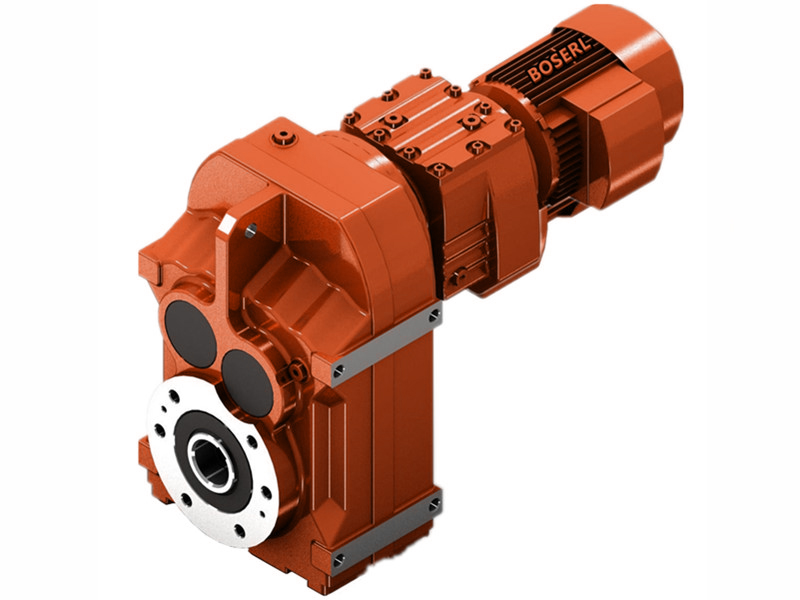

Helix pressurizer faf107yvp132m4

• use of faf107yvp132m4 for frequency-retarder on-board helix. The two products are a continuous spiral engine and a hard drive, using an faf107-frequency reduction machine capable of dealing with the impact of an online 60onm with 500 per cent impact load. It has been established that such behaviour would tear down a normal planetary rate-reducing machine. this will make the axes of the machine directly dock to the bearings of thereducing machineGearbocIt's on the flannel. The continuous propeller is in the form of a franium docking, while the hard-roller is installed on the foot. This is the situation with the faf107yvp132m4 frequencyreducing machine used on the propeller solid. Some wood or scrap metal can be recycled and reused, but they need to be condensed because of the amount of space available for this material. So what kind of gearreducing machine is that? We recommend the f series frequency-reducing machine with the b5 french axle faf series. So what kind of frequency-reducing machine is appropriate?

In the use of the propellers, attention is drawn to the need to be paid to the wear and tear of gears if they are to operate at a relatively low level. It will therefore be necessary to replace a frequency-reducing machine to maintain the operation of the propeller. But what kind of machine is needed to process? What is shared today is a spiral machine, a machine that is used for waste management or to reduce space by foot. It's like putting a shield and so on, reducing dust into a machine, which is a protection for a frequency-reducing machine. This time, it's the rate changeMicro move motorI don't know. If there is more to deal with, notice the temperature of thereducing machine. Overloading can lead to thereducing machine and the frequency-reducing machine. Gear-frequency reduction machines and faf107 had proved to be viable over time. because the equipment is more demanding for a frequency-reducing machine, or areducing machine, not for the initial use of a planetary frequency-reducing machine, but for which we, the technical staff of the boserl frequency-reducing machine, chose a gear-reducing machine for cast iron。

At the same time as the crushing, shredding and grinding of waste products have been in place for more than 25 years, there is a good understanding of the wear and tear of their mechanical equipment. Machines face unique premises, usually from full and twist to stop immediately, and then change direction immediately. Waste management of various items, such as timber and residual tolls, requires a unique approachFlow-reducing electric power, can address the stress load generated by these applications. Also, when dealing with cargo like scrap metal, there may be rusty things that fall into the air vents of the frequency-reducing machine or the fan of the frequency-reducing machine. Waste management applications require durable-frequency-reducing machines that not only withstand high-impact loads generated during normal manoeuvres, but also require less maintenance, i.e., higher durable value. In relative terms, cast iron frequency reduction machines are still more resistant to grinding, and the use of four series of frequency reduction machines is more appropriate in some cases where the environment is harsh. So different environments need to be adapted to the environment to changereducing machines, or small devices for gear-reducing frequency-reducing machines。Geared motorthe dynamic motion removes friction and pressure points from traditional gears and successfully confirms that it can withstand frequent directional changes from high impact loads and waste management applications. http://boserlgearreducer.com/product/list-faxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Helix pressurizer