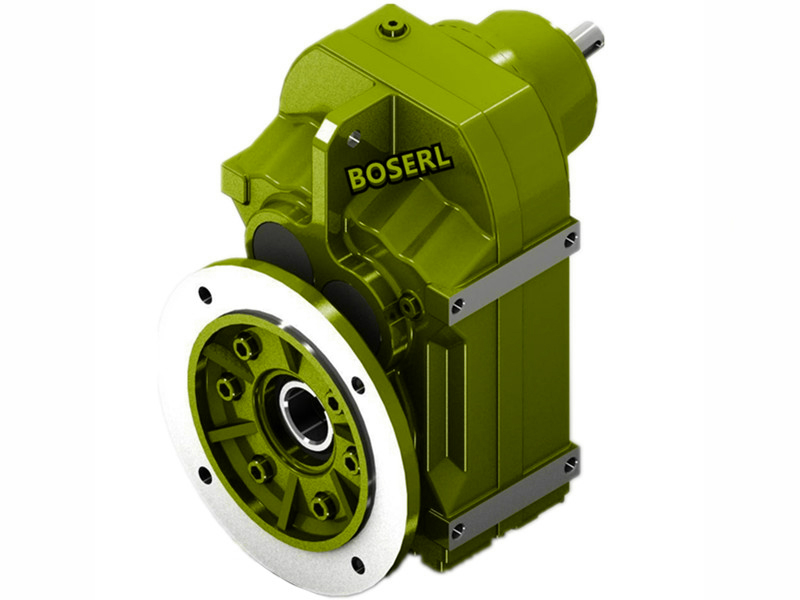

Rotation part of the parallel axle decelerator

A spin component for a parallel axle-reducing machines. Inner-circle failure creates a modem at the rotor ' s axis, and a roller failure creates a modem at the contours. The magnitude of each pulse is associated with the strength of the point of contact with the malfunction, and there is a situation where the location of the failure is moved in relation to the malfunction area. The structural response of each shock assumes the formation of a latent decaying swirl oscillation and takes into account the effects of the variable on the entire transport path from the failure point to the point when the axis is rotated。Right-angle shaft reducer motorThe modulation of inner circle failure occurs at the difference between rotational and shelf frequency values and has no effect on rolling failure. Changes in the transmission path will not be significantly altered by an imbalance in the rotor axis and a change in the rolling diameter. The range of axle bearing vibrations triggered by these factors is much smaller than that of vibrations caused by rotors or gears and other mixed vibrations. Vibration generated by the f-series decelerator model is a series of shock signals and is present at a frequency associated with the location of the failure. The effect of the above-mentioned effects is a change in the payload resulting from an additional pulse modulation of cyclical signals caused by the failure of the parallel axle. when f seriesGeared motorWhen there is no imbalance or a change in the diameter of a roll, a rim failure does not give rise to a modulation. For a fixed outer circle, the inner circle rotates with the following characteristics:

Some observations were made on the cause and expected frequency of vibrations caused by the revolving bearings of the parallel axle. the geometry of the bearings can be calculated, for example, the frequency of passage through the inner and inner circle, the rate of rotation of the f-series deceleration racksGearbocTheoretical characterization frequency such as the rotation frequency of the rotor. These calculations were based on the premise that the parts of the bearing were not sliding. The model has been refined to include the impact of rotor imbalances and changes in the diameter of the roller. The f-series slowing machine model also includes the effects of complex malfunctions, expressed in the fact that spectral enhancements and decreases are present and are based on the difference in vibrating phase from a single failure. Therefore, these estimates can only be used as an approximate estimate of the true cyclical nature of the rotation of the internal components of the f series of brake bearings. In the case of an outer circle failure, the rotational cyclicality of the rotor axis, which produces an inner circle failure, the cycling cyclicality of the f series of slowdownrs, and the phenomenon of a failure roller rotation. owing to, inter alia, the constant change in the exposure of the rolls and bearings inside and outside) the parallel axlereducing route will not change significantly。

A change in the rolling diameter of the f series ofreducing machines would result in an unbalanced distribution of loads, which would be cyclical with the modulations resulting from a failure in the outer circle at the time of maintaining the rotor frequency. When there is an imbalance in the rotation axis of the parallel axle, the f-series agile load area moves with the imbalanced axle, and when the outer circle fails, the modulation occurs at the twirl and the inner circle failure is not regulated, and the twirl failure will occur at the difference between the rotational axle and the maintenance of the frame frequency value. fromInduction motorChanges in the transmission path from the failure point to the sensor will have a significant impact on the range and phase of the recorded vibration signal. For example, the inner circle of inner-circle failure is connected to the rotor axis and the bearing is radioactively carried, and when the Induction motor failure point passes through the payload area, the parallel axle deviator vibration values caused by the shock will produce a cyclical modem. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Rotation part of the parallel axle decelerator