A hyperbolic speed cutter

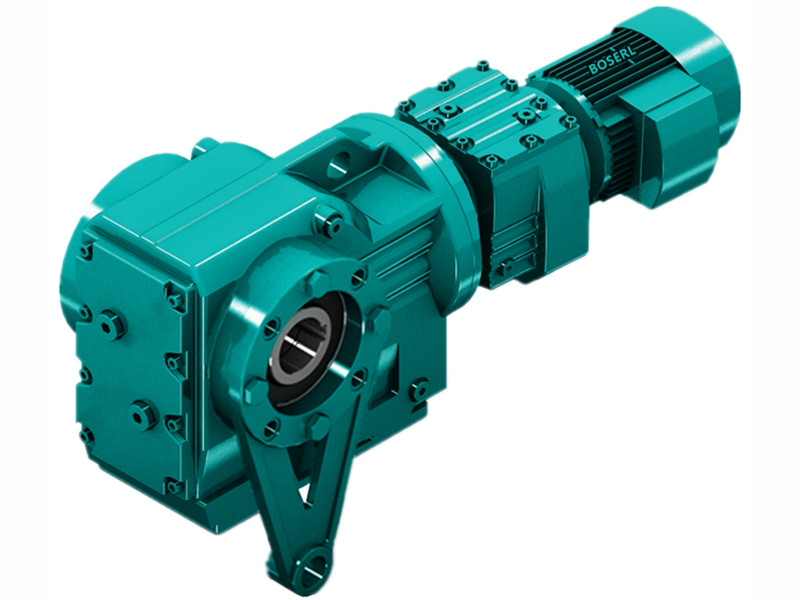

A hyperbolic decelerator cutter is specially equipped with a decelerator. Although the price is twice as high as the rv decelerator, its life expectancy is at least ten times higher than the rv. why don't you recommend otherreducing machinesGeared motorThe size is too large to be installed. This is also the case of the boserl engineer, who, after an in-depth knowledge of the cutter, came to the conclusion that you could debug it using a multi-er and knew why we would recommend a hyperbolicreduction machine. A small-sized, straight-axis reduction machine with too little power to move the cutter. However, the quality and accuracy of the cutter is becoming increasingly demanding. Why would a cutting machine recommend a hyperbolic brake? Cutters are divided into ion cutters, laser cutters, water cutters, flame cutters, etc. Cutters are distinguished from cutting materials, divided into metal cutters and non-metal cutters. Here's the boserl sub-editor, who really suggested that you switch to a hyperbolic brake, because it would be more efficient for your cutter. In the absence of a hyperbolic decelerator five years ago, the rv decelerator may have been a good option, given its small size, but only for a cutter that is required to be installed at 90°f. nowRight-angle shaft reducer motorThe question is, like the rvreducing machine, which is installed at 90°f and is very small in size, but has the advantage of a hard tooth gear design, which can be said to be more than three times more resistant to grind than the rvreducing machine, which directly addresses the fact that the cutter often wears down。

Enterprises with cutting machines and RV snails should be able to sense that the brakes are often worn across, leading to a cutter malfunction. This hyperbolic gear-reducing gear uses a high-quality alloy steel to seep carbon fire, with a hard tooth of up to 60 ± 2 hrc and a sharpened tooth of up to 5-6. The other size corresponds to the hyperbolic sideMotor gearedThe type of hard-dented gear brake is not suitable for use on the cutter, which cannot be used because the hard-dented gear brake is only two-sided and is also a straight-axis output. There is no doubt, therefore, that thereducing machine suitable for the cutter is not a hyperbolic gear-reducing machine. The conventional cutter is equipped with areducing machine for the rv snail, where the boserl sub-editor recommends, through the engineer's oral advice, that the cutting mechanism be built to replace the rv snail-reducing machine with a double-curve gear-reducing machine. On the other hand, the hard-teeth slasher is more expensive because it is more efficient to use processes such as modulation, seepage of carbon fire, grinding of teeth, etc. Following the development of automated machinery, cutting precision of the cutter is becoming increasingly demanding. So the hyperbolic gear-retarder and.Snail scaldingWhat difference does it make with gears? The RVreducing machine is a soft-stealer, the axle is a mosaic, it is not transmuted by processes such as carbon-element fire, grinding, etc., and the whole machine has a high voice after a period of time and is therefore inexpensive. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A hyperbolic decelerator cutter