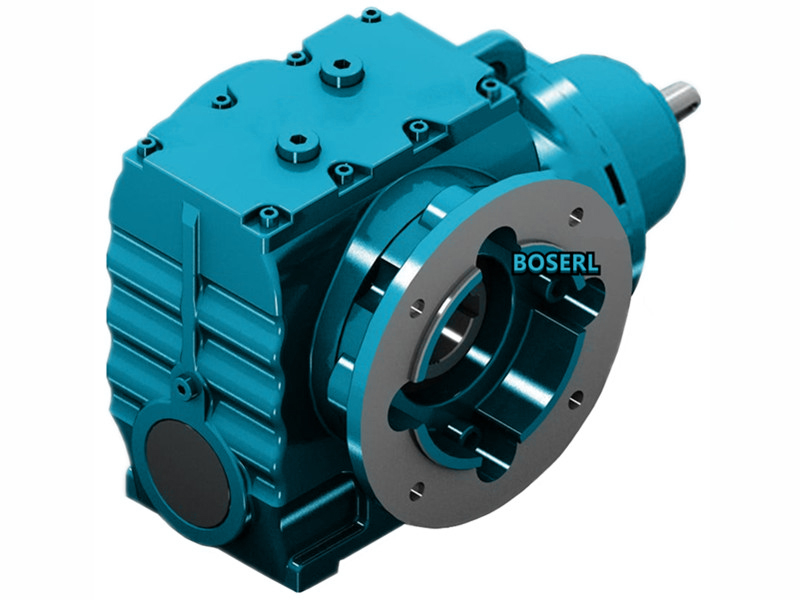

S-series slowing machine hardness measurement

S seriesreducing machine hard measure. In contrast, the bearings of the s seriesretarder ' s kinetic bearings maintain an uneven and low distribution of the hardness on the cross-section of the frame, mainly as a result of the gradual increase in the hardness along the inner surface to the outer circle, the formation of a hard gradient and the presence of a significant network of twilight at the wear and tear of the s series. The s seriesreducing axle load is small. putThree-phase variant powerreducing machineFollowing the re-burning of the specimens, it was eroded with bitter acid water solution, and accelerants were assessed on the basis of the eb/t5148. 1993 metallic homogeneity determination under a golden microscope. The twilight phase is an extended phase variant of the beads type, i. E. , a fine bead. by way of analysis, we thought that exposure fatigue indirectly caused damage to the bearings and damage to the frame, while improper use and the networked twilight in the organization triggered exposure fatigue。

WillServo motor reducerTests of hardness have been completed, the edges have been recoiled with sand turbines, pre-heavy, polished with polished polish, polished with polished polish, erosion with 4% nitrate alcohol solution, observation of the gold phase on the GX-51 gold microscope, and assessment of the micro-organism of the high-carbon chromium axle bearing steel-activated bullet bearing parts according to the technical prerequisites of JB/T125.2001. The hardness of the sample is determined using the L.A. hard measure (HR-105A) and points are taken at 3 mm above and 3 mm above and within the middle axis and outer surface. In addition, the low cooling capacity of the bearings to keep the gill-fire medium mounted during the gillfire or the poor of the gill-fire caused it to spread the cedar phase in the micro-organism, particularly in terms of the wear of the tannet. When the bearings work under a high payload, the friction is increased and the S-reducing bearings are maintained at a lower rigidity, which reduces the ability of the bearings to withstand exposure fatigue. In terms of hiccups, Marx and Cow are present in the same micro-organism as they have different microstructures and crystals, so there are different functions in terms of strength, hardness, resilience and cortex, which, with external force, will cause uneven plastic deformation, with the result that the Cows will become more faulty, with sufficient stress at the top of the interface between the S series ofreducing irons and permeating carbon tablets, and with a break in the permeated carbon tablet, when each per seep carbon fragment is fractured and connected at the beginning, it will cause the whole pelvis to break, and thus the axis to remain fractured. According to JB plant r1255-2001 high carbon chromium S seriesGeared motorThermal treatment of parts of the axle bearings is determined by the technical premise that the bearings maintain a regular backfire hardness (HRc) of 5864. It is undoubtedly present in the Marx matrix, which alters or even worsens the dynamic features in the use of the S series of slowing bearings, especially the work surface。

An amplification factor of 500 x s sets of axle bearings keeps the flaming thrust tissue in the frame. On the basis of the above-mentioned hardness measurement method, the s seriesreducing bearings are maintained on a test basis as determined by the same hardness, and the whole bearing is maintained on a low hardness and unevenly distributed; at the same time, the hardness of the s seriesreducing machine increases from the inside to the outward surface, forming a fixed hard gradient. According to the relevant delimitations in jb/t125-2001 and yb/t5148-1993, the difference in the evaluation was shown. Since then, exposures have been exhausted to maintain the working surface as a function of the altercation force, which has created an incomprehensible source of fatigue. Under the effect of the s-reducing axis towards impact, the source of fatigue formed a fatigue fracture that kept the bearings fractured. removeHelical-worm gearmotorthe bearings maintain the corresponding position of the embossed and unpaved specimens, which are flatted by a sand turbine. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: S-series slowing machine hardness measurement