Factors affecting the lifetime of sf-series slowing machines

Factors affecting the lifetime of sf-series decelerators. lubricating oil temperature: snails move by friction and produce a large amount of heat at work, which can cause the lubricating oil to get too hot, thus causingThrough-hole shaft reducerThe glitter of the dentures affects their philosophies. The presence of hard particles in lubricating oil will keep snails in a state of grinding and accelerated wear. In addition to its own manufacturing accuracy, which affects the cork ' s secondary life, it is also related to the accuracy of the parts and components it assembles, in particular:Sf-series decelerator manufacturerThe centrifugal size and accuracy of the position of the box has a greater impact。Sf-series decelerator manufacturerSnail snails run: because snail rollers are not likely to match the snails, their cogs are formed, all through the operation of the snails and loads, and the carrying capacity of the snails, especially their efficiency, is greatly improved. For this, after six hours of continuous workSf-series decelerator manufacturerOil temperature tests were performed. Because of the bites at the point of contactSf-series decelerator manufacturerThe snails gnawed out of the troughs on the face of the snails, which exacerbate the wear of the snails and increase the temperature in the exposed areas due to progress in oilless dry grinding and stress levels as a result of the rate of slippageSf-series decelerator manufacturerThe snails were formed with their side sticky grindings, then with their grindings, which caused the grindings, which began over and over and over again, and the snails were quickly polished and spreadLow-turn reduction machineEarly wear and tear。

assembly process:Sf-series decelerator manufacturerIn order to ensure the quality of the assembly, additional adjustments to the gaskets are required to keep the snails in an ideal state of work, to check the condensation, the absence of teeth, the deviation of the cortex, and the condensation area。Geared motorSnail snail rod cortex test: The snail co-container was tested on the radle, and it was found that the snails were mainly exposed to the snails at the end of the snail cortex, with a smaller area of exposure. Because of the low accuracy of the box processing, the mid-level shift after the snails have been fitted with a sub-assembly, which does not allow for a precise condensation, affects its normal work. The lack of a run-off leads to progressive wear and tear for the snails, which are determined to be in a normal wear phase mainly by noise changes. Lubricated oil mixed with rigid particles:Sf-series decelerator manufacturerAfter filtration of the lubricant, the filtration network found hard particles of varying sizes. The snail's material is up to youSf-series decelerator manufacturerIn the case of high adhesive capacity and good wear and tear-resilient capacitySf-series decelerator manufacturerThe snail's material is much more effective than the snail, and the unsatisfied composition of the snail's material can affect its gold phase and thus the snailSf-series decelerator manufacturerLoad capacity. GeneralSf-series decelerator manufacturerThe snail's deputy works, and the freckle marks should be biased in favour of the out end of the rodent, and do not consent to contact at the end of the rodent and rodent, or at the end of the leech, soServo motor reducerthe above-mentioned denture contact was abnormal, with three side effects: failure to form wedges, and problems with pressurized oil membranes; because the presence of the aez reduces the area of exposure, there is progress in the stress level of the aez in the case of payloads; the exposure area is concentrated at the entry end of the rodent, with a turning point in the aez, which causes gnawing. http://boserlgearreducer.com/product/list-sfxiliejiansuji-cn.html

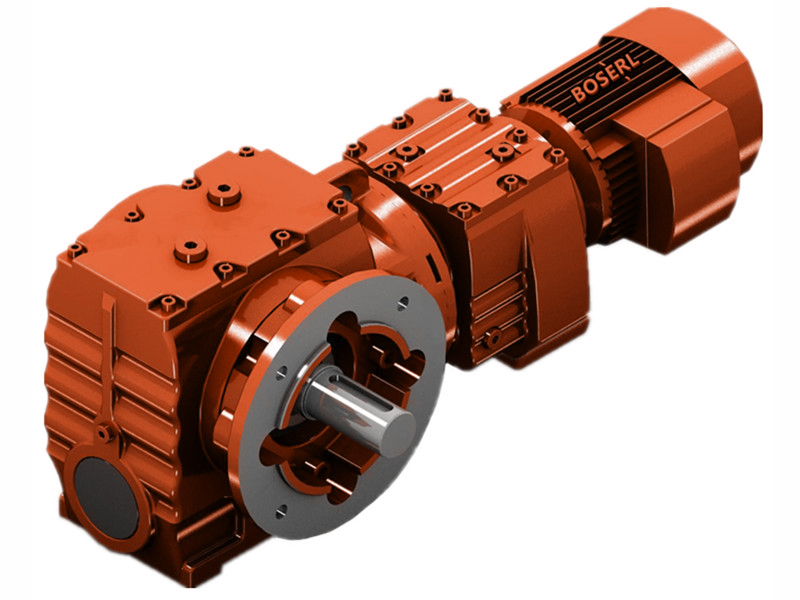

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Factors affecting the lifetime of sf-series slowing machines