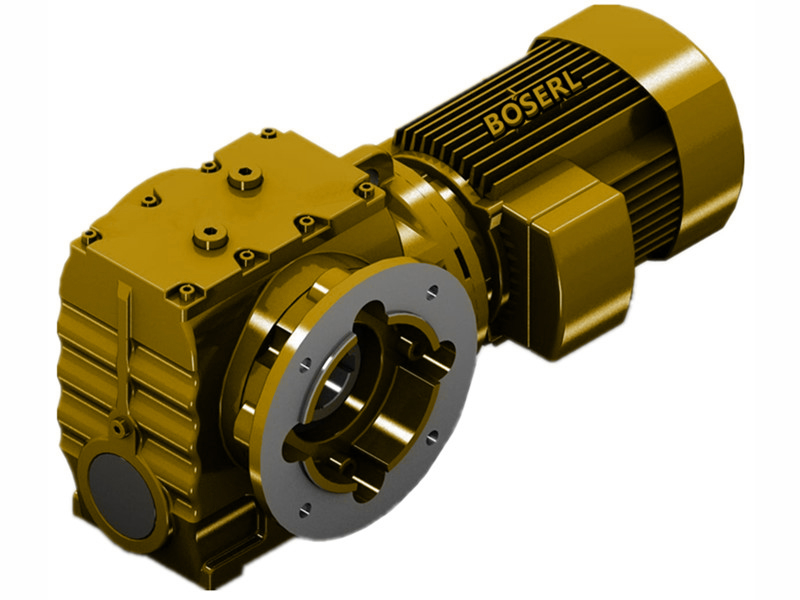

High temperature improvement at the axis input end of cold-bed saf series

The cold-bed saf series input output axle end temperature improvement method. if any of the system's components fail, it doesn't affect in a short timeSaf series deceleratorsOperations and lubricants. Therefore, in order to advanceGearbox motorThis setback was finally addressed with good results through a reduction in the rate of lubrication, a reduction in the rate of accidents, and adaptation to the actual situation on the ground and the way in which the lubrication was done. Technical adaptation: to reduce snail snailsSaf series deceleratorsThe following measures are in place to enter the output bearing temperature and equipment failure rate, the lubrication effect of progressive equipment and the start-up rate of equipment. The fluid was kept in the middle of the perforation hole, i.e., it was provided with oily lubrication inside the container as a backup. (3) Snail snailSaf series deceleratorsThe failure to clean up and replace the fluid on schedule has resulted in long-term use, grinding and depletion of the fluid in the case, the fluid becoming dirty, higher temperatures, changes in various performance indicators for lubricating oil, deterioration of the oil quality and a significant reduction in the lubricating machine. The third is on every oneSaf series deceleratorsSet up three nozzles inside for spray lubrication. However, according to the actual situation at the production site and the operation of the lubrication equipment, the cold-bed snail snails were foundSaf series deceleratorsThe high temperature at the input output axle end, especially in the summer, is above 90 oc, causing multiple damage to the bearings and severe wear of the teeth, which severely affects the timing of production. cold-bed snail snailSaf series deceleratorsRare oil lubrication topics: (1) Higher temperatures under cold beds and snailsSaf series deceleratorsNo heat insulation on the surface. (4) Higher temperatures below cold beds, spot and giveThree-phase variant powerreducing machineFuels are unsafe and unfeasible, and sometimes, as a result of poor spot-checking and low fluid levels, they do not really function as oil bathing, often causing significant equipment failure, and they are easily burned with steel when they are measured and refuelled。

Effects analysis: snail snailSaf series deceleratorsA significant reduction in the temperature of the cool input output axial end of the oil not only reduces the wear and tear of the equipment, but also improves the anti-heating, anti-aging, leaks and prolongedSaf seriesGeared motorService life; as a result of the system being implemented with a wheel-back oil bath and sprayed lubricants, snailsSaf series deceleratorsThe fluids in it are in a state of activity, and they are relatively clean through continuous rotation to cool the dust, and the temperature of the fluids is roughly between 40 and 50oc, and various performance indicators are good and lubricating. (2) snailsSaf series deceleratorsFixed oil bathing and lubricant temperatures are used to operate with snail snails, with a gradual increase in temperature, a significant decrease in lubrication, a reduction in the useful life of seals and a continuous oil spill. And now..Saf series deceleratorsThe temperature of the thin oil inside, the control of the oil table is better, i.e. the size of the cooler selected, the pressure of the system, the size of the high-voltage ball valves, the size of which is appropriate for the system, the lubrication effect of the high-pressure valves, and the use of both the oil bath and the spray double lubrication in the design of the system, which has resulted in better lubrication, which has significantly improved the snail snail polesSaf series deceleratorsThe lubrication rate. The first is to establish a rare oil lubrication system, which is required to have a wheel-back oil bath and spray lubrication in order to reduce oil temperature, progress and lubricationSaf series deceleratorsThe failure rate, based on the drawings and the actual situation on the ground, establishes the installation of the entire rare oil lubrication system and ensures that the fluid remains in the middle of the perforation hole, i.e., in the best position for oil bathing. Second in eachServo motor reducerAn insulation layer is installed and a high temperature, grinding and oil-resilient entrance seal is selected. The cold bed, which is an essential support equipment for small-scale bar workshops in the iron and steel industry, is designed to transport and unload rods made from the roller, which are cut in multiple lengths, to cool down to 100-300OC on the cold-bed gear, which is then collected by the cold-bed underlay device and sent by the output wheel to the cold-cut to a fixed-footed product. http://boserlgearreducer.com/product/list-safxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: High temperature improvement at the axis input end of cold-bed saf series