How do you choose a one-to-one-to-one speed-reducing machine for a mixer

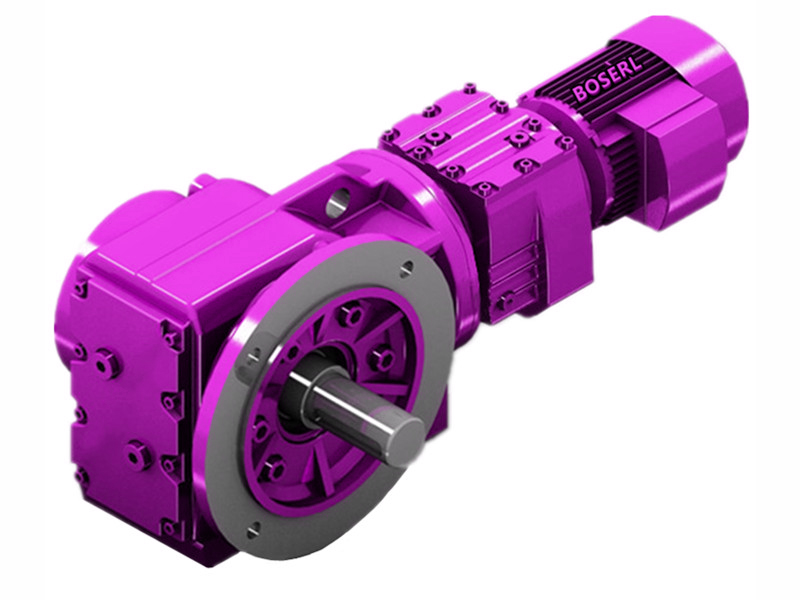

How do you choose a one-to-one-to-onereducing machine for a mixer? Different machines will be asked to choose different machines, and one user in the short term will need to choose the corresponding electric andreducing machines for its mixer, but he does not know how much of thereducing model and the power of the power of the electric power combine to meet the detailed requirements of its equipment, so after a rough calculation, it gets a rate-reducing ratio of 61 for areducing machine, and how should it fit the corresponding model? These are some details of the user's equipment, but in these circumstances it is not easy to choose the detailsGeared motorThe model and the power of the electric power are matched. Each end of the frame shall be fixed with a block and the surface of the two-man stand shall be applied to the two ends of the lower part of the unit, respectively, in order to bind the lower part of the unit. Thereducing machine selected technical staff will then select the corresponding model according to the user ' s parameters and provide detailed size drawings. The user fixes the outer surface of the lower cylinder unit with the body of the tube and the support pole of the tube to prevent the scrolling of the frame of the tube when the mixer is used。

We're going to need areducing machine. These data are provided by the user, who is an elector of thereducing machine for thereducing machine and who is not aware of the user ' s operation, so the detailed equipment requires the user to set the detailed parameters himself. During the production of some materials, it is sometimes necessary to mix different raw materials and then to mix them at different levels and at differents, as if they were fodder or some fertilizer, depending on the circumstances. The hanger consists of a barrel and an electric rack, and the lower cylinder unit is installed on the frame and drives the serverReducer+MotorDismantling bolts are installed on thereducing motor rack. When a mixer is repaired or replaced, such as a mixer axis, a mixer oar and a scraper, the nut is unloaded, and the rolling upper cylinder unit opens the mixer, and the maintenance within the roller is performed. Let us then look at some details of the user equipment and the topics that need to be noted in the selection process. if you don't know how to match the electric andreducing models, you can consult the boserl-reducing technicians to give you guidance on the type

In the user's selection process, his request was to use the power andHelical-worm gearmotorA combination of 61-to-61down ratios, but it is not known what parameters the accelerator needs to function requires, as if the total mass of the mixer material or the total volume and, in the case of loads, how much the mixer will need to provide in one minute to fully mix the different materials. In the case of mixing material, the scraping plate is compatible with the inner surface of the mixer, which removes the material attached to the surface of the mixer and prevents the material from being placed in the surface structure of the mixer, etc. Let's see some details about the user's equipment. The material to be mixed in the course of use is placed from the feed point into the mixer, the driver-drivenreducing machine drives the scroll of the mixer axis, and the mixer oars on the mixer axis flows at the same time as the mixer axis, while the material moves in the direction of the delivery point, when the four series ofreducing drive units are completed. Some are mixed with the other, others with the other. Welding at the top of the frame of the cylinder has a support pole for the tube, which is used in an arc-down direction in the centre of the support pole for matching with the lower unit, which is placed on the support pole and fixed with the frame of the cylinder. Whatever equipment selects the corresponding power andMove the corner boxthereducing model needs to be considered - the load of the equipment during operation and the requirements of the operation, the model being selected only if required by several parameters. http://boserlgearreducer.com/product/list-kfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 1-61-61-61-61-61-61-61-61-61-61-61-61-61-61-61-61-61-61-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-50-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-01-