How do you choose the axle-reducing machines for 8363?

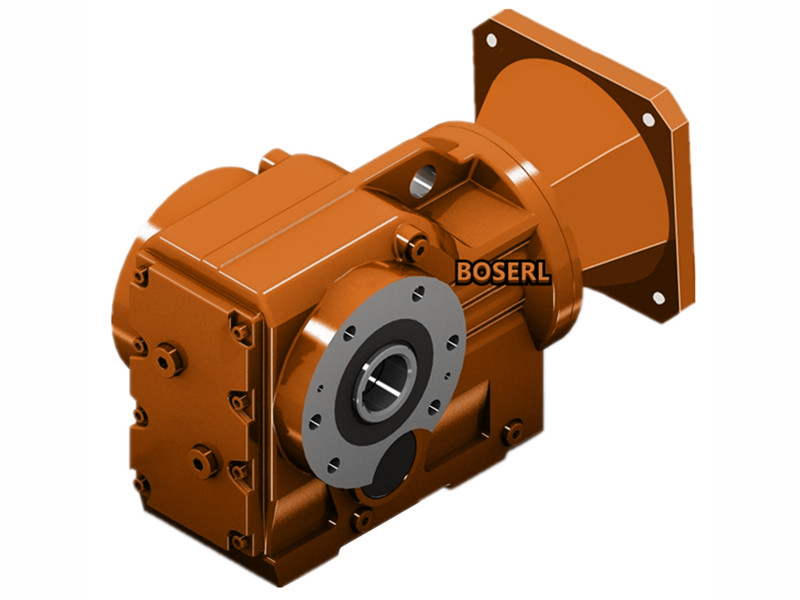

How does the axle-reducing machine of 8363 compare to that of carpentry machines? The input twister of the gear-reducing machine = 200 ÷ 95% ÷ 8363 = 2517 and then the power of the power of the machine by calculating the output twist of the electric machine obtained is 0369 kw rounded and we select the power of the machine of 037 kw for matching use. at this point, the corresponding model is:Helical-worm gearmotor, s57, s67, if you choose a k-series, straight-angle, you can match the rate reduction ratio of 8369, which is closer to user requirements than the two above. At this point in time, when the corresponding output rate is 16 spins per minute, the output twister is 210 nm, and the corresponding model is thereducing machine k37 and thereducing machine f, the rate-reducing ratio of thereducing machine is not exactly the right rate-reducing ratio, so that only needed adjustments can be made using a variable frequency machine. How do you choose in this case? If you have long-term attention to the advice on the boserlreducing machine, it should be known that only one rate-reducing ratio in the course of use is not sufficient to meet the needs of the selected type, so the user needs to provide an additional parameter to satisfy the selection requirements, and the user can provide the power of the gear-reducing machine or the load of the equipment. The useful parameter for this calculation is the electron power of 037 kw, and thereducing machine has a rate of 8363. There are no 8363s and 84s close to the s-series scalder. both parameters are more direct in choosing a matchGear-retarding machineYeah. so at this point, we, the technical staff of the boserlreducing machine, will have to calculate how much power we use and what kind ofreducing machine we can match to achieve a rate of 8363。

In the recent use of a carpentry machine, he designed a carpentry machine that was more efficient and easier. He's looking for us, and he wants us to match himDouble- power decelerator, which allows the drive equipment to be sufficient for the rate reduction ratio of 8363. The two lower-rate ratios that were closer at the time were 8653 and 8065, which could be adjusted by choosing the two lower-rate ratios, which corresponded to the output- differences between the flat-ratereducing machines f37 and each of them, allowing the user to choose the appropriate one for use on it. When this deceleration ratio is selected, the output is 16 turns per minute, the output twist is 215 nm, the axle direction load is 5790, the safety factor is 14, and the corresponding decelerator model is r47 or rf47. Different equipment may be used in a different way, resulting in different internal structures and internal devices being used in the design of the machinery. If the r-type decelerator is chosen at this time, there is no just-in-time deceleration ratio, which is closer to 849. So what we're going to figure out is how much of the electric twister. since the three-symmetric walker is used, there are some differences in the rate-down ratio during the selection process, so long as the output and the twisting is adequate for use, the need can be calculated by communicating with the design techniques of carpentry machinery and the user calculates by a series of parametersGeared motorThe twirling of the output at 200 NM is enough. The following is then calculated using the 4P electrical parameters, and the output rate of the power is selected to be 1,400 rotations per minute. Then let's see which of the four series ofreducing machines is more suitable for use on the equipment. http://boserlgearreducer.com/product/list-kaxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 8363 to speed-down. 8363 to speed-down