Oil spills from the gs snail snails

Oil spills from gs snail snails。Gs snail scalding machineThere were no vent masks, the axle was sealed with wool and oil collars, but there were no leaks。Servo motor reducerFragmentation background: The oil spill has been severe since the launch, not onlyGs snail scalding machineAll of the axle leaked oil, and there were multiple oil spills in the upper and lower compartments. This is the use of paper ' s elasticity to compensate for the gap between the top and the bottom of the surface, which is spread out because it is uneven。Gs snail scalding machineFault management: to address the above situationGs snail scalding machineOn the subject of oil spills, take the following measures:Gs snail scalding machineThe top-covered refuel hole covers each of them (as the construction period is limited, it cannot be installed above the top of the top; large holes are drilled below the axle shears, so that the oil in the sheath can reach the tank; large snail snailsTilt gear brakesthe upper and lower boxes must be flat and not easily processed. it is still possible to seal the axle with wool, which should be purified and 2mn higher than the trough。

Two small onesGeared motorThe case is cast iron. It's bigGs snail scalding machineThe hood is welded with steel plates and the next box is made of casting steel. In recent years, the use of molybdenum disulfide dry membrane or semi-dry membrane lubrication can address the root causesGs snail scalding machineOil spill title. This time becauseGs snail scalding machinethe inspection period was short and the axle seals were not easily retrofitted, resulting in a slight leakage of the remaining axle. in the past, there would have been small gaps in the use of paper as a cushion in thin industries. the table below shows the figures. only a slight permeability of the axle was observed in the 2h continuous test through a high- airborne vehicle and in the 8h continuous test with a load. the top covers are welded and easily deformed, making it more difficult to fit the upper and lower sides. in order to be completely leak-proof, generalGs snail scalding machineAfter cleaning, a test button from the upper and lower crates is applied, and a reduction box is used to measure the large gap on the side, and a paper pad is selected for the industry, which is thicker than the detected gap, and is then sealed with paint. Half a month later, the review found a leak in the windshield, which was analysed to be small and underpressed in and out of the box, which should be replaced by a large windshield and should be fitted inGSSnail scaldingup high. the industrial paper feeder is an oscillation, and the cut-off at the axis is parallel to the axis. in order to address the issue of severe oil spills, some plants have adopted a chimney-type long tube-to-winder windshield, which has increased the pull, so that both the inside and the outside of the box are ideal and effective, but less beautiful. the wool is supposed to be immersed in oil for 24h。

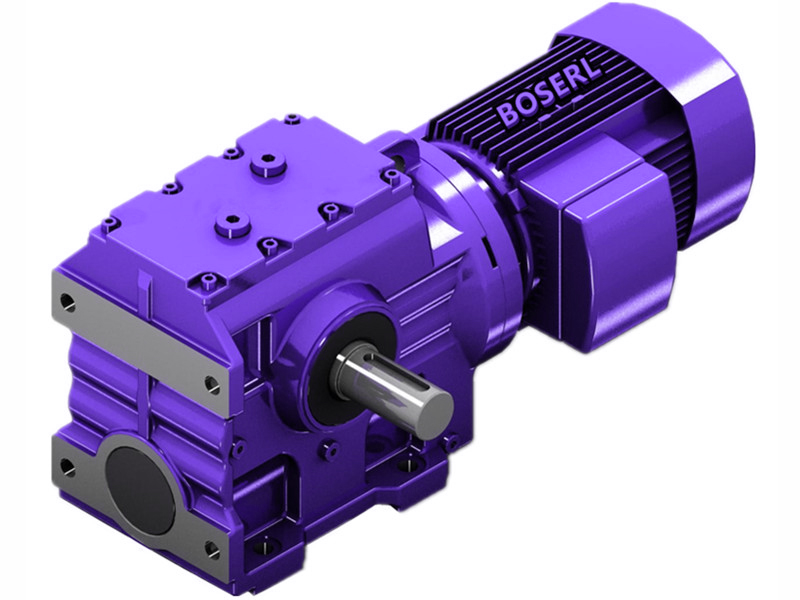

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Oil spills from the gs snail snails