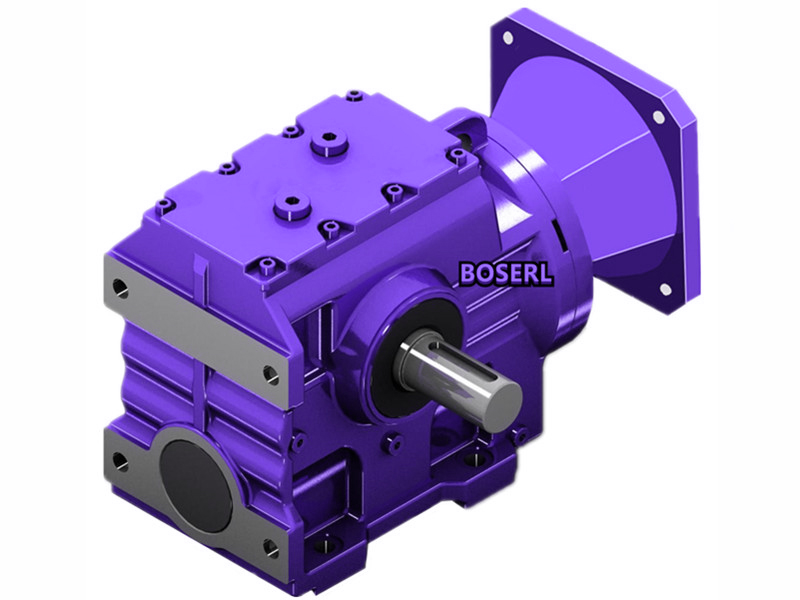

How to improve the accuracy and efficiency of the assembly of s-series speed-reducing machines

How to improve the accuracy and efficiency of the assembly of the s seriesreducing machines. combining of moving bearings: based on the type and the nature of the bearings, they are assembled in different ways, and when the inner circle of the bearings is more closely aligned with the axis, while the outer circle of the bearings is more loosely aligned with the hole in the box, the bearings are first mounted on the axis, and then the bearings and axes are loaded into itMotor gearedIn the case, when the inner coil of the bearing is more closely aligned with the perforation of the inner coil, the bearing is pressured into the shell, then the bearing is fed into the shell, and when the inner coil of the bearing is more closely aligned with the contours, the outer coil of the bearing is more closely aligned with the perforation of the cavityHelical-worm gearmotorThe bearing is pressured into both the axis and the shell。Helical-worm gearmotorDuring the assembly, two errors may arise: an angle error between the snail axis and the snail axis, and an error in the central distance。Helical-worm gearmotor(b) Technical requirements for assembly: to ensure that the snail axis is perpendicular to the snail axis; and that the symmetrical line of the scalding gear is within the symmetric plane;Helical-worm gearmotorThe snails in it shall have an accurate central length of the condensation; they shall have an appropriate contour gap and an accurate contour surface; For snails for different purposes, there are different technical requirements for moving structures, and snails for spectrometers should be used to minimize the angle of the movement side in motion; for transmission powerSeries sGeared motorIt should be based on progress in the accuracy of its exposure, which increases its resistance, carrying capacity and conveys greater rectangularity. When the excess is greater, the temperature differential is used, with the axis heating with the medium and then with the axis。

At the snail snailHelical-worm gearmotorIn the assembly process, it is necessary to be aware of the requirements of a higher rate of production and economics, in accordance with the existing premises, of the methods used to ensure the quality of the assembly. For conical roller bearings, because their outer circle can be separated, the inner circle may be placed on the axis separately, the outer circle may be placed in the box, and then the lasagna may be adjusted, the bearings may be over-compensated with the axis or the shell for an hour, and they may be balanced by a pressurized method, with a hammer or, on average, with a pressure machine. To meet this requirement, it is necessary to develop a fair assembly process. Clean up the box during the central distance of the cavity, support the box with three kilos on a plane, and insert the cardiac rod into the snailGeared motorIn the box hole, the adjustment of the jack to parallel the plate with one of the cardiac rods, which is to be repaired at both ends of the bar by a percentage scale, and to measure the distance between the two rods and the tablets by two blocks in relative measure, the central distance is to be calculated. An error in the verticality between the measure axes: two heart rods are inserted into the perforation of the box, a pin is placed on the root percentage table at the end of the carbar, is fixed with a screw, a rotor ' s bar, and the reading error on the percentage table is equal to the vertical error of the axis. Snail snailHelical-worm gearmotorPre-assembly inspection: To ensure that assembly technology requires that snails and snail axes are vertically at the same level as each otherHelical-worm gearmotorThe central distance and vertical error of the snail axle and the snail axle are reviewed. Snail assembly: cleaning, cleaningHelical-worm gearmotorShackles, rust, oil stains, etc. on snails, measuring bearings of inner holes and axes, bearings and snailsHelical-worm gearmotorThe actual size of the hole. When packed with a moving bullet bearing, care shall be taken that the end marked with the bearing type should be external, that the bearing side of the bearing is closely connected to the shoulder or hole of the axis, that the assembly is strictly clean and that the assembly is followed by a hand-rolled bearing inspectionServo motor reduceris there a card to block replicas and check the size of the axis noise during work. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: How to improve the accuracy and efficiency of the assembly of s-series speed-reducing machines