Axle bearings of the rectangular gears are not improved

imperative gear-reducing bearings were not sufficiently improved. it is the removal of the originally designed axis, where a single-column ball-rolling thrust bearing is installed, supported by an axle and axle-ring, with a 1 mm gap between the outer circle and the axis to prevent the bearing from bearing the trajectory, to ensure that the radial strength of the gear-axis is fully supported by the routing axis. therefore, taking into account the requirements of the production process in a comprehensive manner, the round-turn is kept at 6.3 r/min while replacing damaged bearings to maintain production. solutions:Motor gearedthe spare parts were not available, and it would take six months to produce the spare parts, as the gear-reducing machine was operational, taking into account the timing constraints of the production and the cycle of gear-reducing power generation, beginning with a defined approach to maintaining thereducing performance. the second is the short life of the bearing, which can be sustained by a simple replacement bearing short-term man, given that the bearing of the gear-reducing power plant has lapsed for three months. based on the power of the motor required for different rotations, the strength of the gear gears and the bearing lifetime of the gears of the gears of the gears of the gears of the gears having been calculated on the basis of the manual of mechanical design, when the gears of the gears of the gears of the gears having been rotated at a rate of 5r/min, each of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the gears of the units of the gears of the gears of the。Zip gear reductionThe operation resulted in severe noises, increased observation of its high- axle-axis two and a half to take over the end, a preliminary determination of the damage to the gear-reducing bearing, and an open-angle examination of the sky, which revealed that there were large amounts of silver metal particles on the side of the lower side of the gear-reducing machine by the main input axis, confirming the preliminary finding。

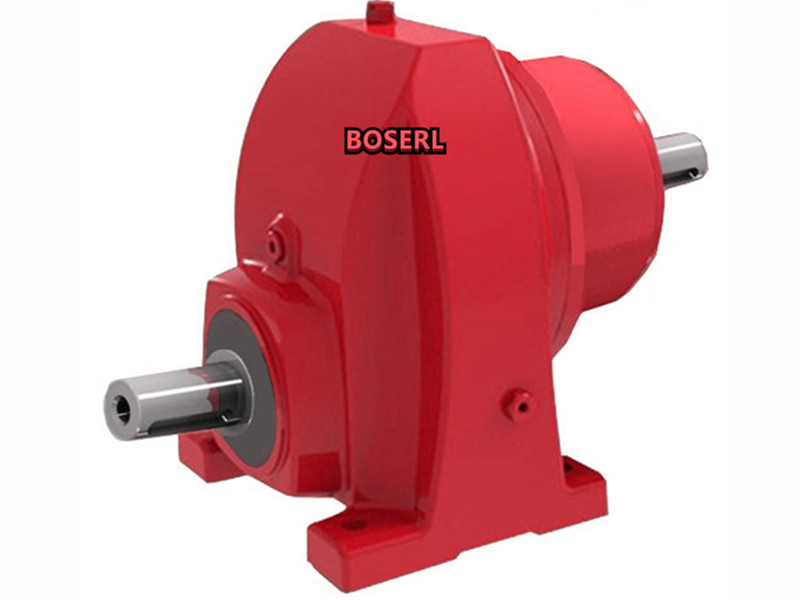

In the form of a hard-to-penetrate car, this gear-reducing machine is designed to improve its carrying capacity and to stabilize the transmissionThree-step-down powerThe gears were all wheeled with tilt gears, with the two-column plume roll bearings selected, and this damage was caused by the bearings being the first bearing near the side of the main moving axis, with only a column of the two rolls of the bearings severely worn, and in a separate row, the cause of the damage to the bearings caused by the loss of lubrication was excluded from the condition of the bearings, which was seen as a result of the movement of the tilt gears, which produced a larger axis, and the damaged rolls were the column rolls that bore the directional force of the axis, with a preliminary analysis of which there was a high probability of damage as a result of the excess of the bearings. This leads to the conclusion that the gear-reducing machine is too small to be fully aware of the requirements for low- transmission power. This gear-reducing machine has been lubricated as a mandatory rare oil lubrication, so a new lubricated oil hole has been added to the upper body to ensure lubrication of thrust bearings. Practice has confirmed that, after retrofitting, the bearing life of the bearings has been extended, in particular the axle bearings, which have been more advanced. Each of the two-axis bearings is required to be fully utilised when the rotor turns at a higher rate of turn-off, so that the common-way control cylinders can effectively extend the service life of the gears, from the time when they are converted to the time of useGeared motorin the case of the opener, it appears that all gears are in a better state of condensation, and that the gears do not extend to any failure, thus judging that the gears can be inherited. the damage to the bearings was due to the fact that the carrying capacity of the bearings did not meet the requirements for use, resulting in the short life of the bearings, which was the underlying cause of the loss of the bearings. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Weaknesses in axle bearings for slow-down machines