Spirillage gear-reducing machine noise source analysis and governance

Spirillage gear-reducing machine noise source analysis and governance. The cortex and the end are processed in the same trap, which ensures verticalityDramatic gear brakeThe pores of the case are slittily, semi-precisionly and finely processed in the bed of the recoil, after the slitting of the box, and the poaching of the two sides with a single eye. The internal and endometric positioning of the axle, which is calculated to be non-localized, and the co-facilitation of the peri-axis, does not require or cause a “bit side”. An error offset is used: the assembly benchmark is based on the lower end of the gear, the main positioning benchmark, so that the low (deep) end of the gear is matched by the deep (slight) end of the gear axis, offset by the error. The axle and the cortex of the gear combine to select h7/k6, and the cortex is tight and does not cause the gear to “bit the side”. The gear-retarded electric case is removed from the internal stress and is not deformed and does not cause the gear to “bite the side” when it is made, after four months of post-prevalence treatment of the cortex, de-spectrum edges and colons. When the reasons were found, the measures to be addressed were as follows: the processor ' s reloading, the re-engineering of the work, and the elimination of the deformation of the stress, but not the economy. Even when the same roller was last processed at the angle of the roller, the gear spreads “bite side”, excluding the effects of the error on the machine bed and analysing the causes of the “bite side” phenomenon. Noise source analysis: observation comparison of high- and low-noise propeller gear reduction machines with uncapped observation. Gear-processing error analysis: spiral-convene gear-reducing machine blades sharpened and well matched, processing a new roller with a new roller, and "bite" of the gear like the original roller, for reasons to be excluded. after the above analysis, the reasons for this can be excluded and are initially establishedTrident gear reduction machineTransformation of process systems. If the grinding norm is not chosen properly, the gear-reducing motor may still cause a run-off after the axle neck。

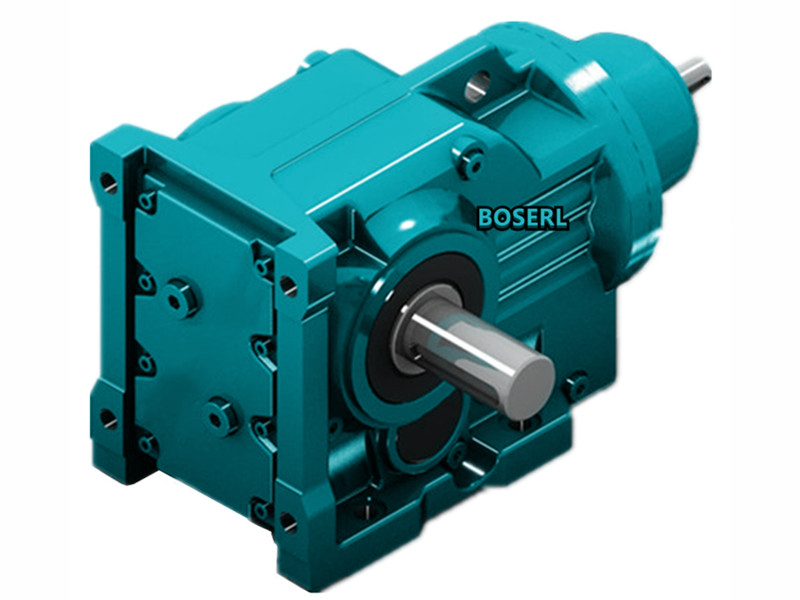

The same type of coil gearreducing machine produced by this plant in bulk has been extended to cases where the rotor gear-reducing machine has low noise and smoother motion, sounds normal, or produces a metaphorically intermittent high noise, which sounds abnormal. We went deep into the production workshop and tested, tested, analysed and improved, and tested with precision acoustics to show low noise gearGeared motorThe requirements of the plant were met, while the high-noise gear-reducing power plant was divided, requiring less noise management. Axle processing error analysis: In order to ensure processing accuracy, the cortex of the gear-reducing electric unit, the axle shoulder and the cortex of the gear were all last sharpened at the same time as the integrated benchmark after a fine study of the central hole of the axis, the milling bed was of good precision, and the processor assembly did not give rise to a “bit side” of the gear. After review, the pedals and pyramids are of good accuracy, which ensures parallelness of the box ' s body hole and does not cause the gear to "bite side " . A roller is installed on the main axis of the roller's frame, and the run-off of both ends' shoulders should be within 0.1 mm, and the side of the shoulder should be within 0.005 mm. When the high-noise rotor gears are re-assembled by error offsets, their reduced noise effects can be blown to rice, smooth and low, and the intermittent noise of the high-noise choreographer has met the requirements of the plant. Based on an analysis of the installation of the rolling gear axis on the roller, the left side of the axis is up, positioned with a pointer, and the other end is positioned with a three-caw cardboard and tightened, and the whole gear axis is determined by the quality of the top-end dumpling, lower design, manufacture and assembly. Low-noise cortex gear-reducing machine has high-precision contact on the tooth, with contact marks on the whole tooth and high noiseSpiral cone gear deceleratorthe lower axle exposure to the gear is less than 50 per cent, i.e., it has contact marks (i.e., “bits”) along the end of the gear in the direction of its width, it has no contact marks (i.e., “no bites”) along the side of its other end (i.e., “no bites”), resulting in a less than complete rading of the gear-reducing motor gear in the width of its exposure, and a high accuracy of the second gear exposure, with a visible noise source on the gear. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Analyzing and governance of noise sources for slowing machines