Paraplegic gear-reducing vinylization and its prevention

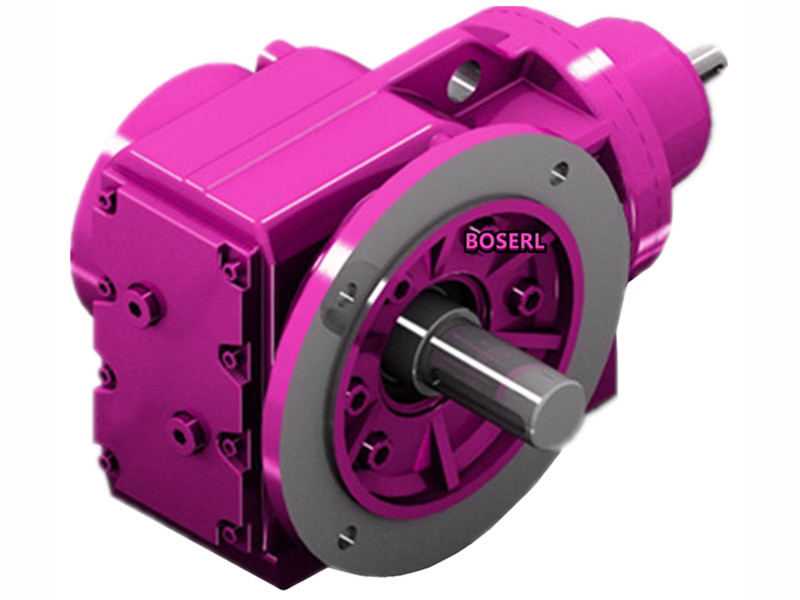

(c) Parastatal gear-reducing carpentry viscosity and its prevention. An umbrella gearreducing machine relies on the contours of the active wheel, which drive it from the contours of the wheel, with the following characteristics:Geared motorThe movement is driven by the cog face, so the force that works on the cog is used to refer to the tug face. In high- or low- heavy loads of high-powered gear gears slows down motors, because of the relatively large or high-temperature cortex pressure of the gears, which easily causes a break of the lubricated oil membrane, causes direct contact with the gears, produces dry frictions or semi-dry frictions, which will increase the temperature, create inherent welding adhesives in the area of the teeth, then tear along the slide direction, form the transfer of surface materials of the tugs, this form of tooth damage in the paratex gears is called cogs, which are visible on the surface of the coatings, peaks, scratches or ditches, and the metal on the teeth of the gears is sticky. Welding to the other side of its condensed tooth, forming a very rough surface, which, when glued, accelerates the wear of the tooth, and renders the gear-reducing powerer obsolete. In this chapter, the mechanisms and hazards of glue from the side of the gear-reducing machine will be described. The progressive viscosity, which improves the stamina of the tooth, avoids, as far as possible, scratching, tearing and stripping of the tooth metal to prevent the adhesive. YesMid-hole output reduction machineSmall gears are carried with a relatively large number of gear thins, and in order to close the life of the two gears, they usually function better than large gears, thus enabling large and small gears to use different materials and each to obtain good mechanics through appropriate heat treatment。

Taking into account the impact of a variety of factors, such as the working environment in which the gears work, the lubrication premise, the materials, thermal treatment methods and the manufacture and installation of gears, in the light of the above-mentioned characteristics of the work carried by the turbostatAn umbrella gear-reducing machineThere are various forms of gear failure, but there are four main forms of . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . The geometric factors of the mosaics, gear numbers, pressure angles, gear shapes, gear widths, as well as precision requirements such as coarse viscosity, surface-treatment quality, and working prerequisites such as, oil temperature, oil volume, oil jet direction, etc., are detailed influencing factors, and proper selection of parameters and appropriate protective measures can prevent and reduce the occurrence of gear-retarding. It is clear that the direct factors that cause damage to the larvae are the load, the relative velocity of the larvae, and the lubricants. The pressure on the gear changes during the conveyance, with exposure at any point in the front of the tooth coming from nothing to nothing, from small to large, and then from big to small, to zero, from the gear-reducing power to the gear, which is primarily convoluted, with the exception of a purified bullet at the end of the wheel, the remaining point of contact at the teeth being a roller-and-roller, and the tooth sector running slower than the tooth sector. In terms of gears themselves, a progressive viscosity and a change in the cavity of the teeth is also an important measure to address the adhesion of the teeth. Reasons for the adhesion of the teeth and their avoidance methods: lubricating oils with high viscosity or anti-fluid additives, gelation of the dents, mainlyGearbocthe oil membrane in the rote rodents has been removed from the lubrication, which directly exposes the surfaces of the two metals and binds them to each other, so that the adhesion does not occur as long as the surfaces of the two metals are separated from the membrane, and the important premise for the membrane presence is the presence of lubricant, which is prevented by the strength and relative discomfort of the progressive membrane, so that it remains a good lubrication at high temperature and pressure. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Quick-down denture adhesive phenomena and their prevention