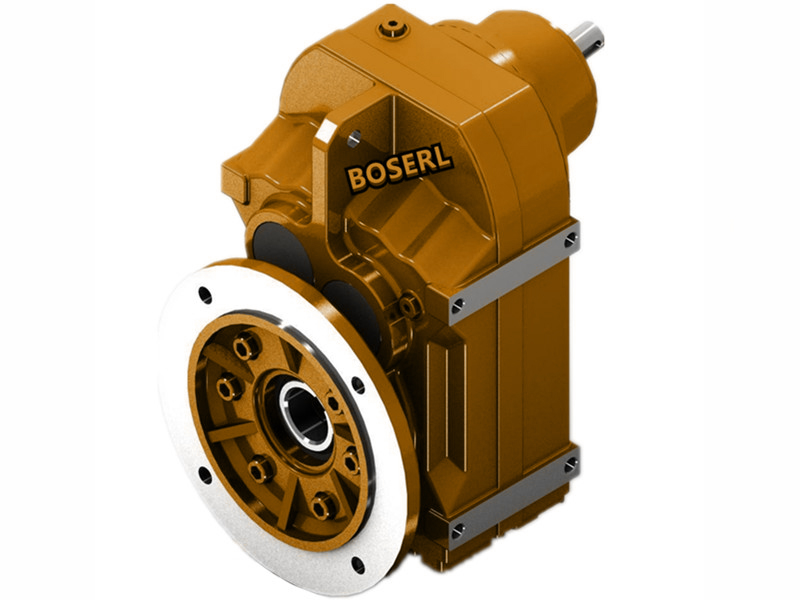

Test and adjustment prior to installation of parallel axle slash gear reduction machines

Tests and adjustments prior to the installation of a parallel axle slasher. (c) Pre-board inspection and adjustment of the parallel axle slash gears: this includes installation-size inspections of the axle sized, the diameter of the ground foot and its interposition, and the height of the main axis. Parallel axle gear-retardation mechanics inspection and adjustment: The purpose of the axle is to ensure that the half-turn hole of the axle bearing outer circle and the sectioned box does not have a “cabus” phenomenon, and that the half-hub sizes of the half-turned cavity of the cavity of the axle do not exceed the value of the assigned scale. After the factoryHangerreducing powerThe container is not sealed in a strict manner during the installation of chillers and heaters, adjustments to the break-up or loss of gaskets, and the presence of impurities and axle lubrication back in the tank of the gear-reducing motor. The co-accuracy of the axle jacket with the box shall be eight and, in this case, 0.02 mm of the plug shall not be inserted into one fourth of the full outer circle of the bearing. There are also topics such as excessive storage time to render the seal tape ineffective, gear gears, corrosive corrosives, etc.; the quality defects of the parallel axle gear brakes are usually caused by the plant in the course of processing and assembly, and typically include an error in the size of the installation, the accuracy of the gear processing, an error in the quality of the installation and thermal processing, an error in the adjustment of the axle gap, a failure of the bearing lubricating roads, the “cartons” of the bearing jackets. The parallel axle slasher is to be resealed with oil labels to check for leakage in the various seals. The back-to-back drive, the transfer axis, should be rolling flexibly, free of sound and blockage. Seal gap examination of the trunks: The check of the box's seals is plugged in, and the length of the case is not agreed to pass by one third of the length of the length of the box, with 0.05 mm of scalding and a parallel axle gear reduction. Parallel axis slash gearsGeared motorIn the absence of thorough detection and adjustment of pre-plants, the abnormal working conditions of noise, vibrations, excessive temperature rises, etc., are regularly applied during the post-partum period, affecting the normal operation of the parallel axle gear-reducing machines, such as the fact that the remaining lubricant oil in the case is spoiled by the long time of storage or that the oil model is different from the current lubricant model, and that failure to clean up results in the deterioration of the fluid by the reaction of the lubricant added to the aircraft。

All of the above-mentioned hazards and defects can be detected in a timely manner before they are on board through detailed scientific tests and adjustments, which can be remedied through dismantling to ensure the uninterrupted working and normal service life of the gear-reducing motor. WhenGearbocAfter the inspection and adjustment of the sub-container has been completed, the gear-reducing motor is to be re-opened and resealed, the sealing tape is to average and ensure that the outer bearings are in close contact with the semi-circle and upper and lower parts of the container, and the removable bearings are to be assembled in their original condition; the bearings are to be marked with a bearing bearing bearing-typed end. The purpose is to confirm the size of the installation and to match the mass margin. (b) Axe bearings for inter-axis inspection and adjustment: Axes for inter-axis inspection methods are plug-in, lead-pression and percentage measures. The inspection was carried out as follows: a parallel axle slash gear repulsor observation hole was activated, the interior refuelling road was checked for smoothing, if the refuelling did not work, marking was required, and the cause of the blockage was carefully checked after the tank had been opened, and the problem was resolved. Open-box inspection: examination of teeth hardness; water cooling and pipe (or heater) sealing; removal of residual oil contamination from the seal and inside the box; axle bearings, gear axes and box cleaning. Quality examination of rodents: The examination of rodents is based on a coloured examination, which should be more than 70% in high direction and more than 90% in length. Axle lubrication back-track inspection: because of the use of the same type of lubricant for gear-reducing motor gears and bearings, splattered lubrication for gears, whereas the axle is used to re-prime the oil from the cisterns inside the tank and the back-column isGear-retarding machineeasy-to-exposures, and the smooth flow of back roads are a central factor in ensuring that the bearings are fully lubricated and that work is not disrupted. it is common practice to press lead, and it is common to adjust the axle gap by adding adjustment pads to the inner and axle bearings or axle bearings on the outer side of the box, which must be adjusted at a scale consistent with the technical scale assigned to the household. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Tests and adjustments prior to installation of speed-reducing machines