The restoration of the lower-speed neck of the coaxe slasher

The restoration of the lower- neck of the coaxe slasher. As a result, this low- gear axis is no longer properly installed. In order to keep up with the production, it is necessary to find a way to repair the axle neck of the gear-reducing power. The grinding results indicate that the gear axles can be used normally. The grinding powder is a “multi-edged” matrix that floats between the development and axle neck surfaces. 80% of 120 degrees of jade, 15% of oil acid, 5% of oil in machine 10 are deployed to grinder, on average, on the surface of a clean grinder and placed in cleanStand-by gear brakesOn each side of the axle, the two individuals, on average, rolled up and down to and from each side of the axle, moving the tires 30 degrees to and from the direction of the axle and moving in the direction of the axle, with the two axes being grinded by two groups at the same time, and often replacing the grinding agent in the process. The first two options are difficult to achieve, with only the third. The general title was mainly inadequate protection of the axle neck surface during transport and processing, with invasive liquids entering the low- axis of the gear-reducing motor, leading to the extension of the previous puddles. They are also often measured to control the grinding size, so that it is averaged in all parts of the area, and the actual axle neck size after the grinding week。

On average, grinding agents are applied to the surface long and grinding is done. In addition to removing the edifice, the grinding must ensure the coaxial slashGeared motorThe coaxial and cylindrical length of the neck is often rotated during grinding, so that it averages the grinding of all its parts, with no grinding of the large diameter gears, with large and heavy parts and extremely adverse rotations. From the practice, it is discovered that during grinding, the neck is rotated at 120 degrees, with three grinding neck weeks, during grinding, it is often measured, it is controlled, the grinding of its parts is averaged, it is carefully measured before grinding, and the original dimensions of the axes of the axle wheel reduction machines are carefully measured, three cross-sections are selected on each of the axes, and four dimensions are measured at 45 degrees in each of the lengths, as a basis for grinding。

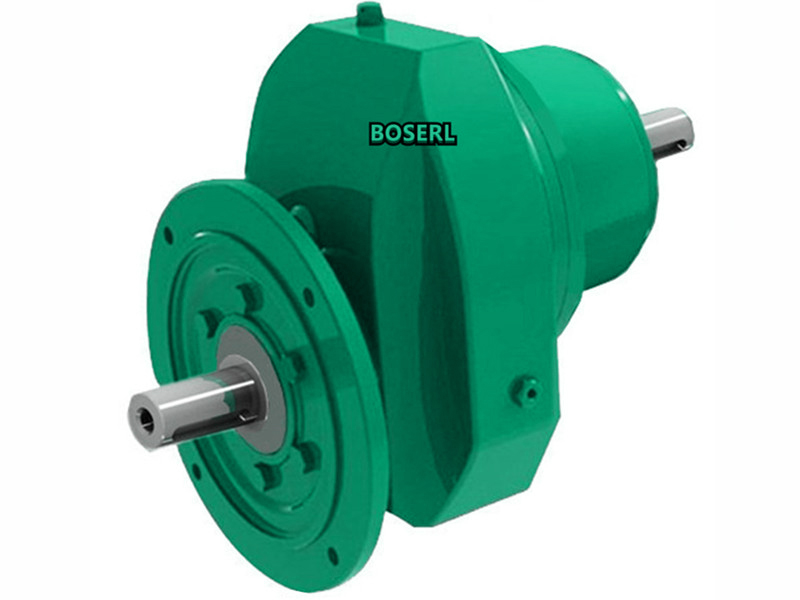

♪ When I'm developing ♪Spiral cone gear deceleratorwhen the neck moves in relative motion, under fixed pressure, it acts as a combination of roller, friction and thawing on the surface of the neck. at the same time, the oilic acid quickly forms an oxidizing membrane on the axle neck, accelerating the grinding effect and obtaining the required size and geometry through repeated grinding. (a) options for the restoration of the axle axle for axle-turbation gear: the grinding of axle necks with sand wheel on the bed of a car is not easy to achieve; the second method is to be transported as a whole to thereducing machine plant, to press the axis out of the big gear hole, to repair the gear-reducing engine neck or to replace the new axis, and to heat the outer coil of the wheel at the time of crushing, which would easily cause damage to the inner and outer circle of the gear; the third method is the production of tools and manual grinding of gears for axles. in the case of the maintenance of the axle-slash gears that i was exposed to, among others, the low--axis surfaces of the gears of the gears presented a ligature, a tear-trace puddle with a depth of 0.03-0.05 mm. the surfaces inside the puddles were coarse, dark, and when twad was installedMotor gearedThe axle neck was coated with tungsten powder and the tungsten tungsten tungsten balm was scraped. The mechanical and manoeuvring process for grinding the motor axle by gear: this axle is 45 degrees of exercise steel, HB218. The hard HT15-33. Painting and grinding are predominantly physical and chemical. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Recovery of the slow-down axle neck