Waterproof design for the vertical gear-reducing bearings

Waterproof design for a vertical gear-reducing bearing. The value of the gap between the axle and the lid aperture is taken as reference to the value of the gap between the bearing cover and the axisMotor gearedThe gap between the axle and the plaster moves to the atmosphere, and the small thickness of the plaster can be determined by reference to the thickness of the axle bearing cover, which is designed to be a 30° C slope outside the sealed gas export, parallel to the surface of the conductor ' s water cycle, and acts as a convection. Waterproof sealing device design: Composed of gas source tubes (e.g. anti-erosion), pressure reduction valves, docking, cut-off valves, filters, sealing lids, trifluorinated conductor rings, micropressure meters, capacitors, silicon rubber, bandages, etc. A standing gear-reducing power plant for water cooling towers, which operates in a water-packing environment for long periods of time, is used with a large amount of condensed water and, after a period of operation, is found to see water seep out of the axle of the poles of the pole-reducing gear-reducing motor. The distance between the water-directing ring and the sealed lid refers to the gap between the sealed lid and the axis, making the best use of the jet power of the gasSpeed brakes slowing downThe structure of the upper and lower seal covers is the same, and the lower part cancels the installation of the conductor rings because of gravity. We can design a water-proofing device for water cooling towers, given the high capacity required for water protection on a vertical gear-reducing axle。

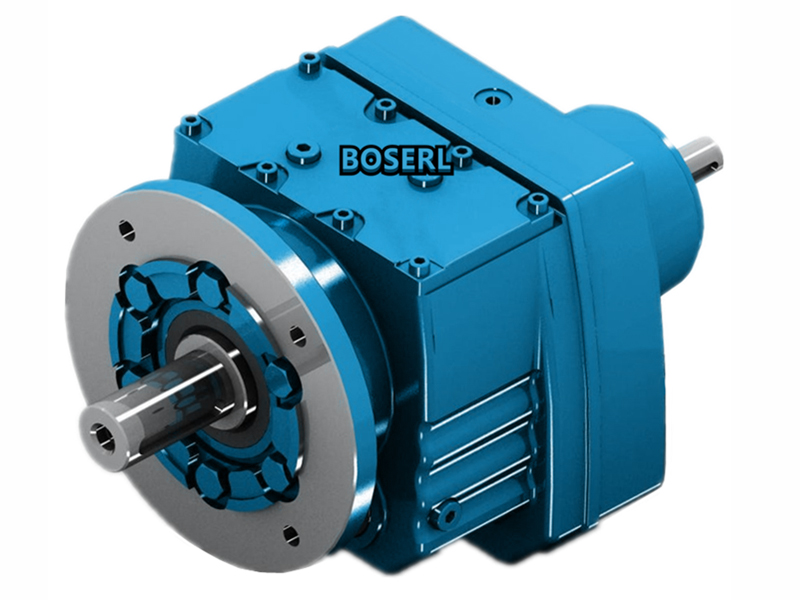

On the upper axle of a standing gear-reducing motor, a conductor-ring is designed with a polytetrafluoroethylene material, with a double-slane design, with an elastic projection to the outer side of a sealed lid slope, and the conductor-ring is held on the axle and must be properly sealed between the axes (silica rubber may be considered). In order to reduce the difficulty of implementation and to guarantee the gearGeared motorThere is no change in the functioning of the departments, and we can use extra-sealed gas for waterproofing. Since the conductor's effect is only a water mist at the sealed gas export site, the sealed gas export pressure is only higher than the atmospheric pressure, with a recommended pressure of 30KPA. In order to minimize the amount of gas used, the water is blocked from entering the inside of the gear-reducing motor by the use of the sealing gas and the conductor. A lid similar to that of the axle bearing on the upper and lower bearings of the high- and lower--reducing gears in the cooling towers, a sealing pad between the lids and the axle bearings of the gear-reducing motors, and a cone structure within the sealing lids in order to reduce the partial loss of the gas and to buffer the gas so as to allow for the average venting of the gas. By analysing the structure of the gear-reducing power plant, it was found that the only way that water enters the interior of the gear-reducing power plant is through a gap between the axle and the bearing cover, so just block this passage and stop itVertical reducerinternally, it is necessary to avoid the problem of the premature failure of the bearings as a result of the water intrusion, and to ensure that the progressive equipment works in an uninterrupted manner. from the preceding analysis, it was learned that water-proofing could be achieved by blocking water access to the inner circuits of the gear-reducing power plant, and that water-entry topics could be addressed through maze seals, mechanical seals, fillings seals, etc., but that the above-mentioned ways of retrofitting were more extensive and expensive and were difficult for factories. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Waterproof design for slow-down power bearings