Gear technology improves the transmission performance of the propellers

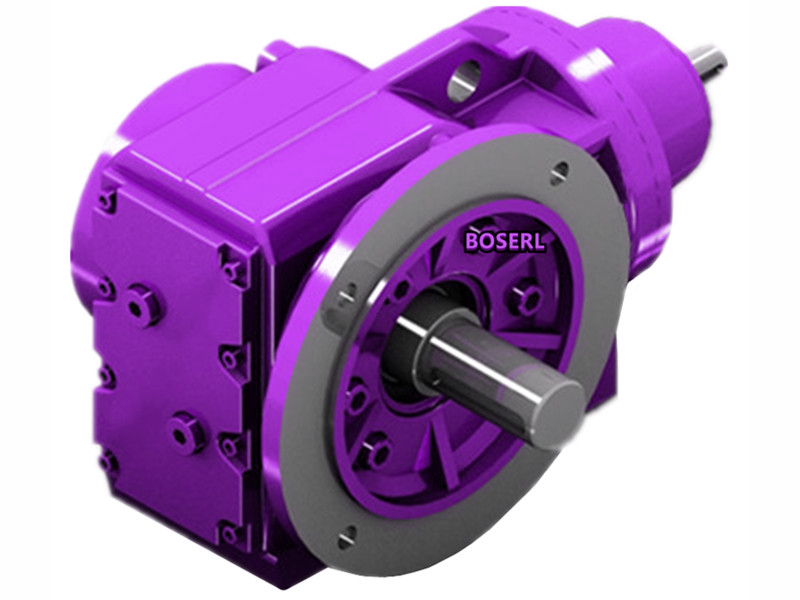

Gear technology improves the transmission performance of the propeller. The principles for the design of gear-retardation gears are: the effect of deformation of gears in the direction of the teeth and of an error in their manufacturing installation on the process of interchangeal transition condensation, to smooth changes in the load of rodents, to reduce the vibration, impact, noise of the gear-retarding motor, and to ensure the accuracy of the area of exposure in the direction of teeth in addition to the impact of deformation of gears in the direction of the gear-retardation and of an error in their manufacture on the area of exposureRight-angle shaft reducer motorThe wide load of gear gears is covered, and the design of gear repair techniques is not the precision of the manufacture and installation of progressive gears, but rather a cost-effective technological method for the removal of the effects of such factors as faults and deformations on the functioning of the gears, as well as for the improvement of the dynamic function of the gears. It has been proven that gear gear-constructing techniques can be effective in improving the work stability of rotors, reducing the noise and vibration of gears, improving the carrying capacity of gear-reducing machines, and extending the useful life of gears, as they are economically and efficiently produced and are already widely used in the industrial manufacture of high- gear-reducing machines。

Teeth design retrofitting techniques concepts and principles: The flow of the rotor gear retrenchor is continuous, with overlapping coefficients greater than 1, the gear-retarder is multi-teethed in the retort, and the multi-dentor justice theory is premised on a test study of “law-to-base equals”, as it is impossible to actually have exactly the same prototyping of two cortangents in the rodents because of unavoidable manufacturing and installation errors, elastic deformation of the rotor, reversal of deformation and the presence and effects of the the thermal deformation of the gear. Based onSpiral cone gear deceleratorThe overall performance and level of the manufacturing process, such as gear rigidity, transfer mode, lubrication temperature, manufacture and installation, based on the results of the cortex analysis, and the design of the teeth at both ends of the dentures involved in the cortex, based on the scale of the cortex, with the retrofitting of the retorts in the high direction of the teeth, including, inter alia, the determination of the manner in which the cortex is fixed, the length of the motitude, and the amount of the retorting; The long direction of the tooth consists mainly of the determination of the drums, the retrospectation of the spiral, and the design calculation of the length of the prosthesis and the amount of prosthesis. Based on the full adjustment of the process of the gear parts, the addition of retrofitting equipment, the retrofitting of the gears, the retrofitting of the gears, and the exercise of the retrofitting of the gears, the retrofitting of the gears, the exercise of the retrofitting of the gears, the process of retrofitting of the gears, the process of retrofitting of the gears, the process of retrofitting of the gears, the exercise of the retrofitting, the process of retrofitting of the gears, the process of retrofitting of the gears, the exercise of the gears, and the exercise of the gears by the retrofitting of the gears, the control of their accuracy within eight-and-half hours, the focus on the control of the position of the teeth, gears, the position of the fundamentals, the shape of the error curves, and the above method, the focus on the control of the position of the retrofits produced by the retrofitting process, the retroping of the curve, the coneGeared motorThe noise fits the scale. At this point in time, in gear-reducing gears entering and withdrawing from gear-reducing interlocking transition rods, carvings will occur, with gear-reducing areas detached from their gears and root positions, resulting in severe malformations, passive rotations, vibrations, shocks, noises and deviations, which are inevitable even in the case of high-precision gears, such as the use of the refinements of the progressive rotor-reducing gears to improve the working quality of the gears。

Designing teeth is a relative scale. Practice has shown that the mundane dents and the theoretical dentures are highly dynamic, especially at high- powerGear reducer and gearboxwhen moving, the mediocre gears do not meet the requirements, and the gears are designed to be repaired, but they have been effective in improving the gear ' s rodent cortex, making the wide load of the gears available and improving the capacity of the gears to slow down motors. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-retarding