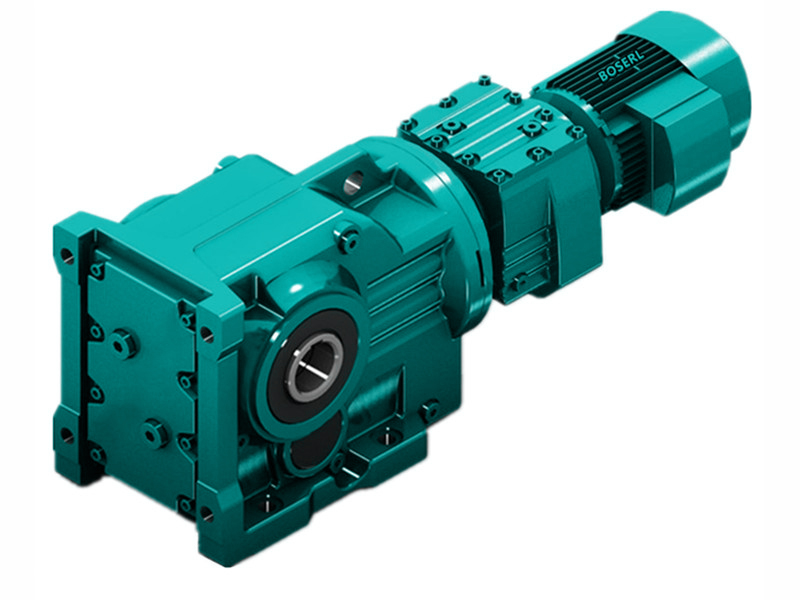

The gear casting process of the k-series speed deviation machine

The gear casting process for the k-series depressors. In the case of exercise, the floor-forming process is usually shared and meets normal needs. Because of the higher requirements for materials, defects, processing and thermal handling of gear casts. The internal tissue density of the casting gear is better and more intense. in this period, we're talking about the k-series gearer exercise, which is directly relatedThree-phase variant powerreducing machineFor our lifetime, we always focus on the gear process, so i'm here today to show you the gear exercise. After processing and rolling, gear larvae, or so called hardening, improves the surface hardness of the gear. Some parts of the gear cast can be welded. You can do carbon seepage for small gears in the k-series slowing machine. The materials of gear castings usually use high carbon casting steel and some alloyed steels with chromium, nickel, molybdenum to achieve high tensile strength. So, there is no need for a higher exercise. It is low-intensity, but it is widely applied to work premises. The buyer should choose the appropriate manufacturing process in accordance with its own money and use. This is because most gears are made of cast steel. For large-scale gearing, you can do surface fire treatment. With regard to the handling of k87 gear gear, of course, all steel castings need to be calibrated to remove internal pressure. In the case of welding of castings at the exercise plant, welding must be refired. The k-reducing gear cast is also known as cast steel gear. Suppose.Level-IIreducing machineIt's extremely hard to roll, so you can reset the fire again to lower the hardness and remove the hard spot. The age of the gears, which have not been hard-treated, is short, ranging from weeks to months. Here, I share some information on the production of gear casts and related heat treatments。

Besides, we're rightMotor-gear reducerThe gear test requires a comparison of the amplitude measured at the same part of the gear tank at different times with the amplitude in normal state, and a state when the scale and normal value ratio is intended to reach a certain level. Large gears are usually less physically needed than small gears. The casting of k87 gears can be used for stricter work preconditions. Furthermore, the order for gear casts is relatively small. For example, when the relative value measure is 1. 6 to 2 times the real value of the normal value, it is noted that when it is 2. 56 to 4 times, it is dangerous, etc. With respect to the k-series decelerator for casting steel gears, such as from gears, gears and inert wheels, the use of stone sand for floor formation is a good option. Some gears are made from casting. As a result, many iron and steel workshops are reluctant to manufacture. For detailed use, the score of 1. 6 times is still a factor of 2 and, depending on the use requirements of the k97 gear case, a higher score of the multiple is used for more crude equipment (e. G. Mine machinery). It's expensive to cast a gear, while it's relatively low to make a gear. Why, because most parts of gear need to be processed. besides, about k97Geared motorcentral and large steel foundries, with a floor formation process using quartile sand, are almost optional. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed reduction gear cast