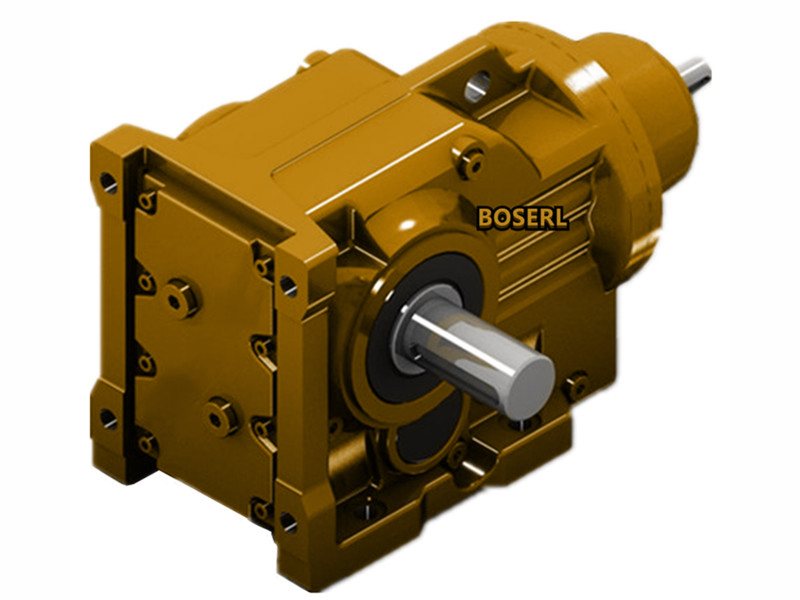

Steps in the installation of a propeller gear decelerator

Steps in the installation of a propeller gear-reducing machine. Heated the bearings, two with complete separation ringsRight-angle shaft reducer motorRoll-axis bearings are loaded into the axis bearing liner and are fixed by the use of the bearings. (c) Stabilize the slant gear cortex within the slant cortex and insert it and use screws to fix it in the slant cort wheel. A ring bearing with a fixed bolt is inserted into the ring carrier's shell. Installation of intermediate-level connector tubes and tilted gear axes, fixed with screws. A small gear axis (part 1620) with calibrated rod bearings and thermal condensation pads is in a vertical position. Two complete tilt ball bearings are pushed to the small gear axis, while they are pushed to the bearing unit. Thermal constrictor rings are heated and placed on a small gear axis. (Use of jettor) Local heating (approximately 20C to 30C) from the bottom to the long of the rotor ' s gear-reducing vehicle (using a blowtorch) and thrusting of the rotor ' s gear-reducing axis into the second. Heating of two tilt roller-columns from the interior and heating of the bearings. Pre-installation of screw gearGeared motorThe small gear axis and bearing liner shall heat the self-reading rod bearing and place it above the small gear axis. A pre-installed connector kit is loaded into a lockring, and a two-way oil table ring and a connector kit is mounted using screws. Heated the axis ring to about 50 °C, and removed the turrets from the cone. Installation of oil dumplings. Seal covers and maze rings installed and secured。

Prior to the installation of the propellers, all the casings and internal parts are to be cleaned and, prior to their installation, all the components are to be seen with no titles and, if necessary, the damaged parts are to be removed and the inside of the propellers is to be placed within the outer casings. The cylindrical ball bearings of the rotor ' s gear-reducing axis are fed into the frame of the outer shell, and then the cylindrical bearings with the rotor ' s gear-reducing unit fixed in the outer shell are fed into the frame of the bearings of the outer shell and fixed with screws. 5.2.5 The pre-installation of tilted gear axes with sealed cover loads the heated coiled gear-reducing rigs into the tilted gear axis and performs cooling. Butter must be used prior to the installation of a propeller gear-reducing machine maze ring, and then the axle gap and inspectionMotor gearedOne-sided input of the wheel's axis's rudder. 180° Rotation pre-installed slashed gear gears with tilt gears (vertical direction). A self-corrected roller bearing, with a rod, is loaded on top of the bearing. Installation of a bearing liner and a reconciliation in a bearing cover. (b) Wrestling the snails of the sluice ball bearings and shelves, and placing them on the shoulder of the axle, and then holding them with a safety frame。

Supporting bearings with small gear axes. Heighting from the outside of the rotor wheel roller bearings, the bearings with gear liners and bearings are fully fitted to the tilt gear axis. Install reconciliations. Installation of separation rings and placement of the oil dispenser with screws into the oil drill of the bearings. Heat the cylindrical roller-axis bearing outer circle and push it to the tilted gear axis, and install a screwdriver gear decelerator safety pad ring。Spiral cone gear deceleratorInstallation steps: The pre-installation of the gear wheel to the cylindrical axis bearings of the cylindrical axis bearings into the frame of the outer shell with the cysts of the frame bearings and the cysts of the cylindrical cortex bearings, and the pre-installation of the entire unit of the cytex and the cysts of the cysts and the second-lined cortex bearings with the bearings of the bearing bearings, with the cysts and bearings of the cortex bearings to be fitted with the cytex pads and a fixed device, and the installation and painting of the paint (blueed ink), and the removal and re-installing of the rest of the gear unit with the wheel gear brakes. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Installation of speed-reducing machines