The problem of hyperbolic speed-reducing machines is resolved

The problems with the hyperbolic brakes were resolved. In the traditional approach to the topic of leakage, there is a need to remove and open the umbrella and axle gear brakes and replace the seal cushions, or to apply the seals not only in a time-consuming and laborious way, but also to ensure that the sealing effects will again leak in operationDouble- power deceleratorThe impact of vibrations has been a good solution for the business to the problem of leakage from the paraplegic slasher. Unfair design of an umbrella and axle gearreducing machine caused oil spills, such as the design of a hyperbolicreducing machine without the ability to achieve an average pressure of a wind-receiver, which resulted in increasing pressure in the tank and spills, while the umbrella and axle gear-reducing machine was being operated with a very high amount of lubricating oil being spilled throughout the aircraft. Leak. If there's too much refuelling, there's a lot of lubricant, and that's what's going on

TargetedMotor gearedThe traditional solution to the subject of wear and tear is welding or plating, which is not completely eliminated by thermal stress generated by welding of high temperatures, which leads to material damage, the easy stripping of components by bending or breaking, and the thinness of coating by electric brushing and coating, both of which are metal repairing of double-curving metal, failure to alter the co-opting of hard-to-hard, which, under the combined effects of the force combination, will again cause wear and tearing, which will be impossible for some large bearings, which will not be solved on site, will depend heavily on foreign cooperation for repair, the use of high-molecular composite materials for the above topics, the application of more cosmprehensible technology products, which have the combined capacity of super-strength pressure-resilting resistance, etc., and the use of high-molecular materials to repair the double-curricular reduction machine, which will have a significant time-saving effect on the restoration of the thickness of the strength of the product, the non-resilence of metal material, and the reduct。

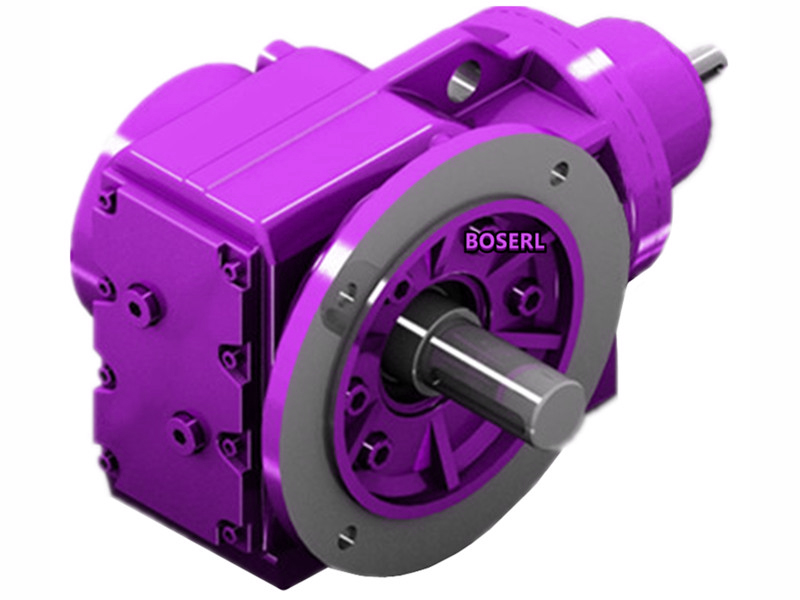

The main types of malfunctions, such as wear and tear seepage, are the following:Right-angle shaft reducer motorThe axle bearings also include the crust, axle bearings, boxes, interior holes, axle bearings, gear transformers, axle bearings. The umbrella and axle gear gear axle axle axle axle wears mainly in the bearings of the axle key, etc., double-curve axle axle axle axle bearing wears and leaks in the side of the axle axle. In response to the shortcomings of the existing slow-down machines, the use of hard-column cylindrical and spiral-patrix gears in the umbrella cortex gears is followed by two whole-modular configurations, which are fitted in a double-curvatured form and reversible rectals to achieve double-curvingrelaying, which not only fulfils the requirements for glucose crystals, but also achieves external product levels in size, weight, ease of installation, noise and shape. In the axle-axis gear brakes of the embargoed umbrella, frictions between the gears generate heat that increases the temperature in the gearing case, depending on the specific law of Boyel Mallow, following the length of its operationGeared motorthe size of the case remains unchanged, so the pressure in the case increases the lubricant oil in the case, which is sprayed through thereducing tank, and the interior wall is leaking from where it is sealed under the pressure. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The speed-reducing machine problems are resolved