Co-axis slash gear reduction axle bearing analysis

Co-axis oscillating gear-reducing axle bearing analysis. The motorized bearings of the axle gears are characterized by a directional impact, indicating that the bearings are operating with a larger axle impact and axle movement. Because..Motor gearedMaintaining the original width of the shelf is 220 Ram, so that this cutting process does not have a significant impact on strength. The same-axis slash gear reduction point of the Motion Section of this steel thermal Rolling Plant has been checked to show that the gear-reducing electrical motor bearing failure was only 6 hours long and the frequency of damage was significantly reduced. In the normal examination of the gear-reducing power plant, a moving bearing was installed for car-cutting processing. If the scheduled stoppage is not carried out, the board from the upper processors will accumulate in large quantities and will need to be reheated, and the lower processors will be in a state of windfall. It was decided that the axle would be physiochemically overhauled by means of chemical component analysis, hardness measurement and gold-phase tissue testing. To improve the analysis of the high level of damage to the vehicle bearings, it is relevant to the mass of the bearings. Thus, in order to ensure the continuity of production of the 1,700 aircraft, it was necessary to ensure the continuity of production. The subject of frequent damage to motorized bearings of amphibious gear-reduction gears was largely addressed. Detailed measures are designed to reduce width by 1.0 ~3.Omm in the direction of maintaining the frame width of pre-asset bearings. YesVertical reducerthe wear of the bearings and the unpaved parts of the bearings to remove the characteristic specimens along the longitudinal strips, all of which are 25 ram in width and are tested for chemical composition, hardness and gold phase. the downtime of the downtime was reduced from 5.5 hours per month to 1.5 hours per month, and the downtime rate was 73 per cent. therefore, the impact of the gear-reducing engine ' s rotor axle shoulder in the axis towards the holding frame is the main cause of frequent damage to the moving bearing。

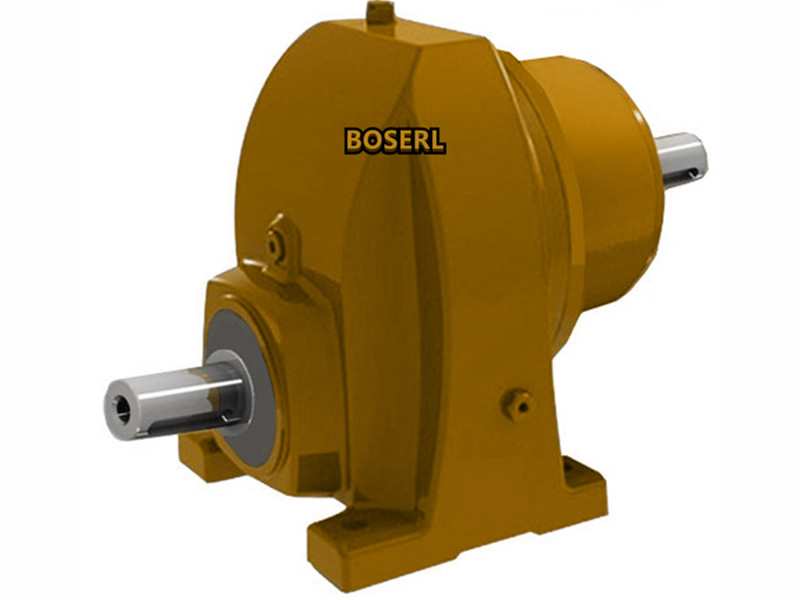

The failure resolution and treatment of the motor bullet bearings of gear-reducing gears is of great importance in the overall production process as the position of the coaxe-slash gear-reducing machines is removed. When the axis rotates, the axis moves so that the shoulder of the axis is constantly collided on the shelf to form the axis-direction impact, so that the axis-direction impact feature is shown on the map. In spectroscopy, it was found on the spectra with an axle gearGeared motorThe effect of the axle impact characteristics has been significantly reduced, which has proved to be an effective means of reducing the axle impact of the gear-reducing power plant. A significant reduction in axle impact characteristics can be seen in comparison. Efforts are made to reduce the frequency of damage to motorized bearings of the same axle gears within a short period of time. Upon study of the relevant parts, it was decided to use an appropriate method to reduce the width of the frame and to artificially increase the shoulder of the axis and maintain the gap between the frame. When the bearings were damaged, the break-up of the holding shelf caused a minor change in the size of the structure, and the gap between the shoulder and the holding of the questions was widened, thus reducing the impact in the direction of the moving bearings. It is hoped that this will be used to reduce the rate of damage to the gear-reducing bearings by moving towards the impact and axis. Gear-reducing motors are graphs of the axle bearings processed through car cutting. On the surface, it was observed that the axial gear-reducing bearings kept dents and plumes on the one side of the gutter on the inside of the shelf, averaged the base rags and formed a fatigue zone from the end of the cutter to the beginning of the fracking crack from the inside of the cut. The analysis revealed that this was due to the greater axle effect on the position of the moving bearing and the greater axle movement of the rotor axis, which is also a common feature of the main gear-reducing electric machine。Hangerreducing powerthe damage to the bearings is not merely a loss of the bearings themselves, but a serious impact on the continuity of the production process. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Axle bearing analysis