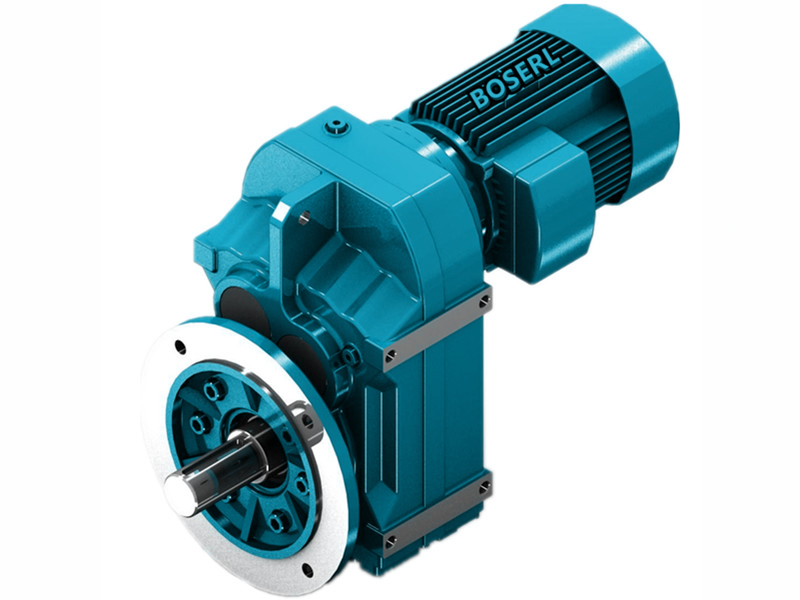

Environmental impact of the work of three arcade speed-reducing machines

Environmental impact of the work of three arcticreducing machines. Manipulating staff using three arcadereducing machines need to be adequately trained to acquire full knowledge of the equipment and products in operation. reducer maintenance workers must be able to adjust, maintain and repair work under normal electrical conditions. The three ambulatoryreducing machines are designed and produced to enhance the technical knowledge of their predecessors and can be used in a safe manner. Three ambulatoryreducing machine staff are responsible for the following:Motor gearedIt also controls the operation of all kinds of manoeuvres, in particular maintenance, inspection and repair prior to start-up, including in-service and after-service. Professional technicians, trained or authorized to perform complex and unusual mechanical manoeuvres. Under the law in force, the buyer is obliged to measure the noise pressure generated by theing machine when it is operating in the context of the differential work to ensure that the noise it produces may cause a resonance in the nearby working environment does not pose a danger to the operator, either after the installation of the three arctic reduction machines or before their use。

The working environment of the three aniso--reducing machines is subject to reference to the following characteristics: temperature between +5 ÷40c and large relative humidity of around 80%. Three iso--reducing machines cannot be used in an open state or when exposed to air. They also prevent dust particles, smoke, gas or water vapour from entering the erosion and wearing the gear. in the course of work, emissions into the atmosphereGearbocNo substances (e.g. gas, smoke, water vapour, dust, etc.) can be produced that are harmful to the health of employees. In addition, it is important for the manipulators to know what is in the user manual. Thereducing machines do not produce high-frequency electromagnetic waves and radiations that are harmful to the health of the workers during their operation. Risks to staff can be completely eliminated or reduced, provided that they are used in accordance with the contents of the instruction manual and that the manipulation of staff is carried out by a trained and sufficiently prepared person. However, when process controls require rapid visual examination, the manipulator needs to be close to the three arcadereducing machines. It was also important to ensure that sufficient work space was available to ensure the safety of the operator and staff。

The scale of the sound pressure of the three aniso-velocity-reducing machines during their operation is measured under different circumstances and the noise from the ground is below 85 dB without any reflections ranging from 1 m to 1.6 m. The vibrations generated by the three aniso-velocity-reducing machines do not endanger the health of the staff. Three ambulatoryreducing machine mechanics need to be able to perform normal adjustments to mechanical components under normal conditions, three ambulatory motorsGeared motorSmall daily maintenance and necessary mechanical repairs. If the departmental maintenance manoeuvre is in an area where there is insufficient light, the user has an obligation to provide the employee with hand-held lighting, carefully manipulating to avoid a shadow, in order to improve the visibility of their work site and its vicinity. Moreover, staff members must comply with the safety rules set out below in order to avoid possible dangerous zones. In addition, when the three iso--reducing machines are adjusted manually, or when different staff are responsible for the use of the equipment (auxiliary manipulators, professional maintenance staff, etc.). In this case, he should be in a safe position for security reasons, and in view of the possible movement of processed materials, it is necessary to keep his vigilance intact。

Responsible for the use of three ambulatoryreducing machines and dangerous area operators. The three ambulatoryreducing machines do not require staff to approach the equipment during normal working hours, since all control panels for start-up and running procedures are located in a secure location. Staff members are required to be informed of the latent risks they face in carrying out their duties, as well as of the operation and accurate use of security devices. The manipulator is responsible for a few simple tasks, i.e. the use of a specific button to think about itInduction Motor 3Phloads, tilts. all employees who are exposed to potential exposure should be informed that the manipulators responsible for machine use do not always operate with sufficient light, that they may be exposed to dangerous areas, and that those who are exposed to them should avoid such risks.reducing machines are not equipped with any lighting, and nearby lighting needs to avoid creating a shadow, thus ensuring the safe operation of the three hexling machines. some malfunctions may cause excessive vibrations, at which point they must be reported and removed immediately in order to avoid dangerous effects on the reliability of the three arcades. http://boserlgearreducer.com/product/list-ffxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Environmental impact of work on speed-reducing machines