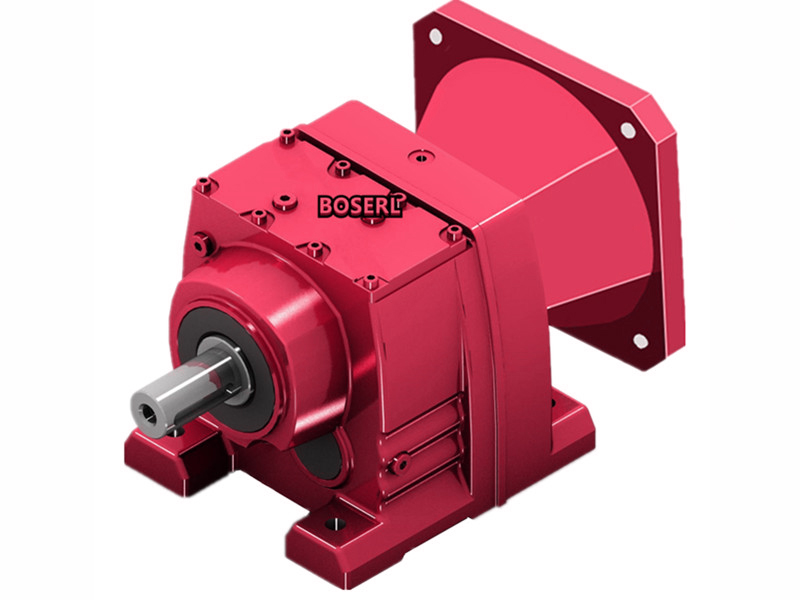

Advantages and effects of oil refuelling in the r series

Advantages and effects of oil exchange in r seriesreducing machines. Attention to the r67 rater's oil level check: when checking the r serieser's level, the power should be blocked to avoid electrocution and wait for the r series gears to cool down, without the risk of burning. the lubrication can reduce the transmission wear and tear of r-seriesreducing machines, and of course it can reduce the noise and vibration of their transmissions, and it can be properly given to r-reducing machinesIt's got a self-lockerLubrication is also being maintained to prevent rusty parts. R67reducing machines should be firmly installed on a non-disrupted, horizontal base or base, and the oil in the discharge tanks should be removed, and the air should be cooled back and out. The process will be completed by twisting the oil piping and the gas vent. Q: why does the r57reducing machine need to be lubricated? Quick questions by boserl sub-editor: 2. 2. The installed set-up ensures that the user will be able to approach the oil billboards, vents, and drains when the process used is to be replaced. editor-in-chief told you about the structure of the r series ofreducing machines, and today we're talking about the benefits and effects of oil exchange for r seriesreducing machines:

Q: what good is lubrication for r-seriesreducing machines? Answer: because r-57reducing machines are multi-pattern grinding gears, there's inevitably some friction in telling the operation. if we want r-seriesreducing to be more permanent and to remain functional, we need to be rightThree-phase variant powerreducing machineUse lubricants. The amount of oil should be kept in line with the installation position, and the oil spot should then be checked at the plume. To see if it works smoothly, without impact, with vibrations, with noises and leakages, the r-series decelerators must be eliminated immediately. So we should not only be careful about lubricating, but also about the details of these. A: it is to say that lubricant acts as a protective membrane on the surface of parts of the r-seriesreducing machines and can effectively mitigate wear and tear from gear grinding, thereby slowing the time-life of the r-seriesreducing machines. If the r seriesreducing machines are not reliable in their sound base, they will be vibrating when they operate, as is the case with noise. open the oil screws, sample the oil, check the viscosity index of the oil, and if the oil is significantly obscurous, it is recommended that it be replaced as soon as possible, for the r seriesreducing machine with the oil plume, check for the oil grade and install the oil plume。

Once the installation has been completed, the correctness of the installation should be checked in order, the various components are sufficiently close to operate flexiblyHorizontal reducerUsing splattered lubrication from the oil tank, pre-operational users are required to remove the conch of the vent, replace it with a penthouse plug, follow a different installation position and open the oil plume to check the height of the oil line, refuel it from the point of oil to the time when the lubricant spills out of the snails of the oil table, and screw it up so that when the oil table is determined that there are no subjects, an empty test operation can take place for not less than two hours. Be careful, however, that thereducing machine should remain hot and hot, with a pick-up under the oil snails, and then turn on the snails and the gas vents and the snails, and remove all the oils, then put them on the snails and inject them into the new lubricant. Friends who have used r-seriesreducing machines should know that they need to change oil, so what do we know about oil-replacement? first, we need to know that different lubricating oils do not agree with other brands of lubricating oil, and that the location of oil table snails, oil bolts and gas vents is determined by the location of the installation, which can be consulted in r seriesGeared motorinstallation chart determined. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The refuelling of the brakes