How do we determine the turret hair of the k-series brakes

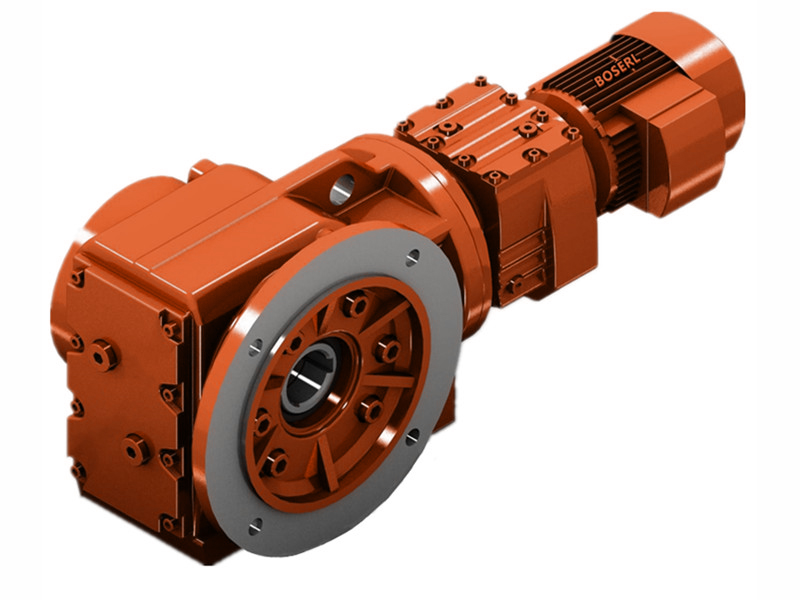

How to determine the turret hair of the K-series slowing machine. Because of the public and technical requirements of the gear parts of the K-series brakes, it is common to determine, for example, that the exercise parts of the gears are common. The material factor for the exercise is M1 because the component material is 45 steel and is a carbon steel with a carbon mass score of less than 0.65 per cent. Since 0.75 is between 0.63 and 1, the external complexity factor for this component is S1. Key slot: Plug in (IT9, Ra 6.3um). The exercise is round, assuming a large diameter of p232 mm and a length of 60 mm, and is available by formula: m = x (232) x 60 x 7.85 x = 19.9 kg. So let's see it todayGearbox motor(also known as an umbrella gear-retarder) for paratrooper fur, we need to know the following curry process for an umbrella gear-retarder: based on the mass of the parts, estimated at m=15kg. 1. The material of exercise, factor M. 2. 2. The quality of exercise. The available denture processing programmes are as follows: two ends: the car (IT11, Ra12.5um) - the semi-precision (IT8, Ra6.3um). The BOSERL sub-coding then led to the specific process methods of the umbrella gears of the K-reducing machine, and, in order to ensure the accuracy and roughness of the surfaces, to take into account the production and economic requirements, the following options were selected for each surface: 2. The surfaces of the parts were coarse, and each of the surfaces of the process was Ra 1.6. Gyms p. 226: Cars (IT12, Ra12.5um) - semi-precision (IT10, Ra3.2um); interior processing programmes with a Motor-gear reducer are as follows:Motor gearedThe foreign circle process is as follows: tooth: roller (IT7, Ra3.2um). S = s0.75。

Now, let's get to the k seriesAn umbrella gear-reducing machineIn order to determine the size of the hair mass and the amount of mechanical residuals, we should first identify the following factors: the gear material for the turbostat is 45 steel. We consider that the gear parts of the k series of turrets often bear the impact load in the course of their work, so we should select the exercise to achieve that the metal fibre is as unblocked as much as possible, and our boserl is able to ensure that the parts are reliable. since the processing of the umbrella gear surfaces of the k-series slowdownr has determined that we can guarantee the quality of the boserl-reducing machine, in accordance with the principles of "bold, first, first, first, first, first" and so on, the process of the k-series-reducing gear has arrived here, as you would like to knowGeared motorThe information can also be obtained by consulting BOSERL editor-in-chief (IT12, Ra 6.3um) - semi-precision (IT10, Ra3.2um) - fine (IT7, Ra1.6um). 3. Public transport, etc., of the exercise parts ' external complexity factor S4. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The turrets of the speed-reducing machine