How to select the k-series speed-reducing drive

How to choose the transmission of the k-series decelerator. Work units need to usechanges as much as possible, as they need to. (b) when the working sector requests a velocities, a stationary movement comparison may be used if it is compatible with the power engine ' s velocity;Speed-down powerIf the rate of movement does not meet the technical and economic requirements, it should be driven by a movement comparison. Requirements for start-ups, brakes, reverses, overloads, slots and emptys should also be taken into account in the selection of a moving device. The k87 decelerators should opt for a simple-structured mechanical transfer under the conditions required by the fixed-motion-by-move-fast capability. The machine is usually transmitted to the machine ' s work unit by means of which the power and movement generated by the engine is transmitted. There are gear transmissions often using gear transformers, and small power transmissions may also be used in turbos with bands or chains. The no-varication transmission takes a variety of forms, with the k87reducing machine having a simple, maintenance-friendly structure, but with a short life, often used for small-power transmission; the liquid no-variant drive is accurate but very expensive. Devices for the transmission of power and motion from the k seriesreducing machines can also be used to allocate energy, change and motion patterns. if you want to choose the right move, you should be satisfiedMotor-gear reducer(b) The requirements of the working sector and the operation of the power engine under better working conditions. The no-varication motion is often used to form a control system to control certain objects or processes, which should be selected according to the requirements of the control system。

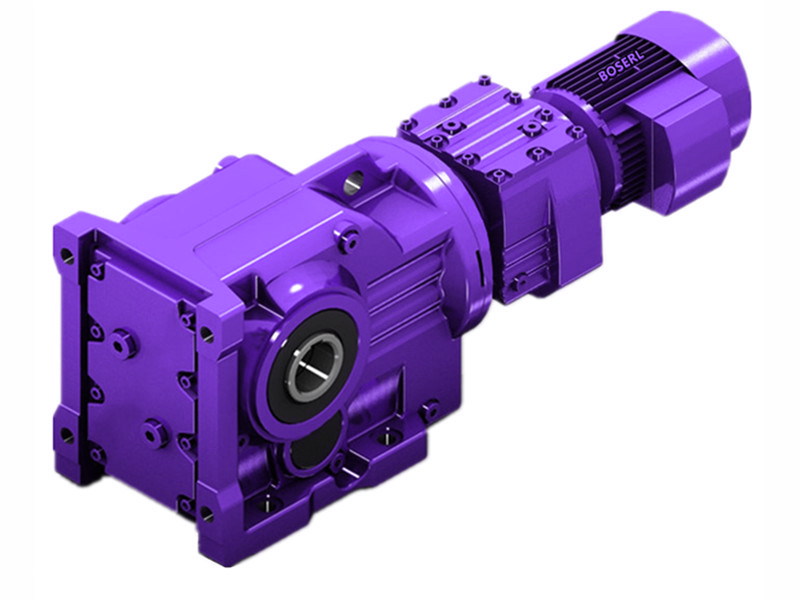

The settings are driven by:Gs snail scalding machine(b) failure to, rectangular and power engines required by the work sector; some machine work units often need to change; the engine ' s output axle is only revolving, while machine work sectors have other forms of movement that require, such as straight-line, spiral or intermittent movements; a number of machine work units are driven by a radio or a few machine work units. The k-seriesreducing belt belt transfer (governed gear transfer) and co-axis transfer is a constant test type, and these topics are addressed by the same line of belt transfer (governed gear movement) with the same angle as the axle movement, which is an angle multiplied by a radius, and thus solves the subject. Of course, the cut benchmark is based on the machine we want to use, and then chooses thereducing ratio, which is better compatible with the mechanical. Small power transmissions often choose to use simple devices to reduce capital. High power transmission gives priority to transmission efficiency, energy efficiency and reduced operational utility. i'd like to give you the first chance to choose how to use the k-seriesGeared motoruse it. last time i showed you the nature of the movement, the more important parameter is the moving ratio, the rate of two moving components in the mechanical moving structure, and the moving belt. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing