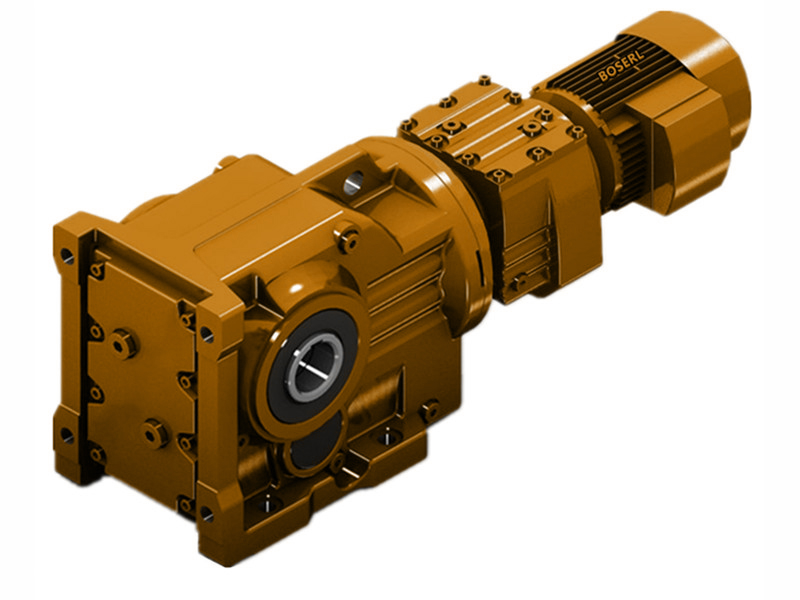

Diagnosis of wear and tear on the k-series speed-reducing engine

A diagnostic solution for wear and tear on the k-seriesreducing axle. the car is moving with the sound of "geden" at the start or at the of the hour, and it clearly shows a feeling of laxityZip gear brakesThe laxity of the gears, not driving the bridge, is clearly the laxity of the axle. The loose parts are no more than cross bearings or steel bowls and crumbs, and tweaked twigs and twigs. Beyond the limits of use should be repaired or replaced. Compared to traditional techniques, high-molecular composites have both the strength and hardness required by the metal and the concessionality (variable relationship) not available to the metal, and can ensure, to a large extent, the repair of the K87 reduction unit and the matching of the size of the component through processes such as “module repair”, “part correspondence”, “mechanical processing”. In general, the K87 axle axis and axle bearing traffic should not exceed 0.13 mm and the gap between the scalable axle and the glitch should not exceed 0.3 mm. Some enterprises with higher maintenance techniques, which often require higher requirements and high usage, use electric brushing, laser welding, micro-arc welding and even cold welding. It's been a long time, but it's still important for the editor to understand usMotor geared plus powerIn addition to the provision of information to potential clients and the creation of a platform for sales and learning, what is to be done in the current period to pre-empt the axle wear and tear。

If you're thinking about the k seriesGeared motorWe cannot ignore the long life of the transmission axis, where welding, corroding, flaying, etc. Are used for wear and tearing, but when the material of the axis is 45 (modified), welding, if only welding, can produce internal stress and, in case of heavy loads or high- operation, can break or break on the shoulder of the axis, can be difficult to manipulate if repulsive fire is used, and has a long processing cycle and a high degree of testing; and cast iron welding is not ideal when the material of the k47 reduction axis is ht200. While wear and tear are inevitable during the operation of the k-seriesreducing machines, sometimes we have maintained them, but we do not seem to see the effects we want. We may wish to shift the line of sight. The moving axes are heavier because of the tasks they carry. It is easy to ignore his wear and tear. The damage, wear and deformation of k87reducing axes and the loss of the balance of movement can cause a noise and vibration in the driving of cars and damage to the parts in question when they are severe. rehabilitate above methodMotor-gear reducerat the same time, the combined upper winds of the compound itself, which are resistant to pressure, bends, spreads, etc., can be used to absorb the impact of external forces effectively, to significantly neutralize and offset the trajectories of the bearings against the axis, and to avoid the possibility of gaping, thus avoiding secondary wear and tear of the equipment due to the increase in the gap. with regard to the above-mentioned restoration techniques, it has become less common in europe and the united states of america, where high-molecular composite materials and nanotechnology are commonly used by developed countries, where high-molecular technology can be manipulated in situ to effectively promote maintenance efficiency and reduce maintenance usage and maintenance intensity, which is widely used in the mikai technology system. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-cutting axis