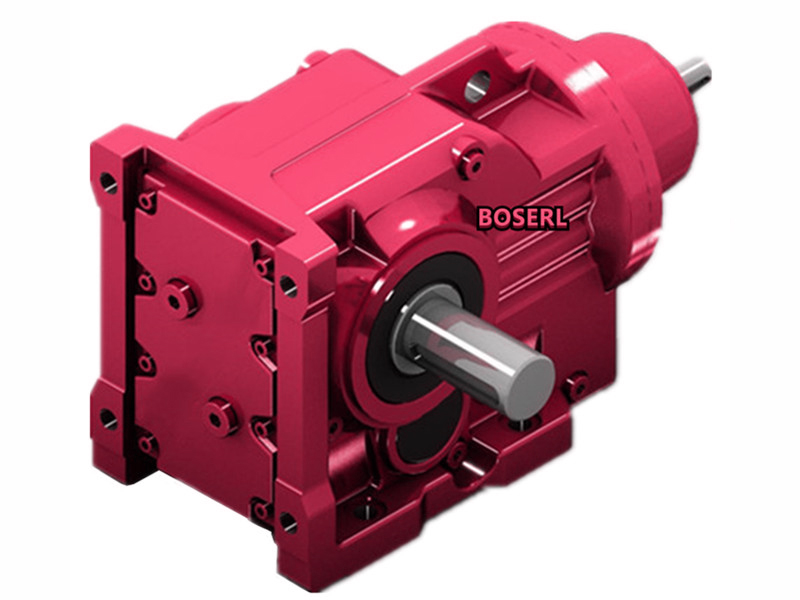

K-series speed-reducing machine oil replacement

Care to replace engine oil with a k-series decelerator. for each lubricant lubricant, approximately 30 grams of lubricant is used, and the position of the lubricant andMotor geared plus powerSpecifications are irrelevant. For this you can use the same type of motor oil as the current cone gear-reducing oil. The location of the lubricant added can be found on the dimensions associated with the order. During subsequent use, and in accordance with schedule, oils must be replaced at all times with spoiled oils containing impurities, contamination, or decomposition, ageing. Note: when you remove the k-series decelerator panel, you must repaint the seal on the seal. Otherwise, can the cone gear brake sealer be guaranteed? Heat sticks should not be broken by scratches or scratches. Upon completion of the preparatory work, a container will be placed below the filling plug and removed from the filling plugs, the piping plugs and the filling plugs; the oils will be released completely; the oils will be refuelled with bolts; and the oils will be pumped with refuelling filters. (b) the power supply of the electric power should be blocked to ensure that it is not accidentally connected before oil is prepared; and wait for the cone gear-reducing machine to cool down to avoid the risk of burns; series kGeared motorIt is necessary to remain at a level that affects accurate emissions due to poor activity of chiller oil. Pipe-shaped heaters must always be immersed in the liquid; a fixed ring of the heating rod should be installed at the bottom of the connector box to ensure the correct position of the seal between the trunk and the upper end of the heating rod. You can use butter to lubricate dust caps or maze seals with lubricable lubricants installed on the thrust and output axes。

The temperature sensor is inserted into the cone gear-reducing tank. The amount of oil should be measured on the scale of the scale; it should be used to check the accuracy of the oil table. Check the required connection temperature on the thermostat. It's newMotor-gear reducerAt the time of the first use, the new oil must be replaced after a 7-14-day drying period. The amount of oil assigned on the stamp is the reference value. Adding the same type of oil to the oil by snailing (or otherwise having to contact the client services department); apostille oil according to the designation on the inscription (see the inscription). Cleaner oil heating units: if oil heating units are formed on them, the oil heating units are removed for cleaning. When the k-reducing machine replaces the oil, you are requested to clean up the residual oil and output axles on the caricature-reducing tank. Installation of oil-heating units: installation of oil-heating units and seals on k-seriesreducing machines. Overheated heating rods may cause an explosion of steam in the engine. A second replacement of new oil is required for use up to three months. in such a case, a cone gear-reducing machine that works continuously for a long period of six to eight months should replace the sub-oil, with no more than eight hours per dayMotor gearedmay be replaced 10-12 months. installation of oil with bolts; installation of pipe plugs; cleaner oil filters, if necessary, to replace filtration cores (in the use of external gas or oil-water cooling units). when unloading an oil-heating device, be careful to block the power before you release the oil. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Weights for refuelling