What are the reasons for the inefficiency of the k-series slowing machines?

What's the reason for the inefficiency of the k-seriesreducing machine? second, the oil tank is covered, and the oil selection is so seriousGear motorsMechanical lubricant hj-40, hj-50 and lubricants such as hl-30, hl-20 gear oil and hj3-28 rolling steel oil are used. The first topic may be the inappropriate installation of the newly installed k-seriesreducing machines, which have extensive wear and tear, although the wear and tear have been divided into several reasons, possibly because of the smoothness, the relatively small gap in the co-optation of the newly assembled spare parts and the fact that, for reasons such as assembly, smooth grease (oil) does not easily form a uniform oil film in order to prevent wear and tear. In any case, the lubricant of thereducing machine should be selected on the basis of the conditions of load, turn, temperature, etc. , and the greater the adhesiveness of the lubricant, the better the difference is wrong. It may also be due to the fracturing of the cosmopolitan size and geometry, which, in the early stages of application, easily eased the previously solid parts by exposure to the intersectional loads of vibrations, shocks, etc. , as well as to heat, deformation, etc. , combined with excessive wear and tear. This resulted in a decrease in the efficiency of the k-series decelerators. clients have responded, whether the new k-seriesreducing machine has been in use for several years, and what's the reason for the inefficiencyGeared motorWhat is the reason for the inefficiencies?

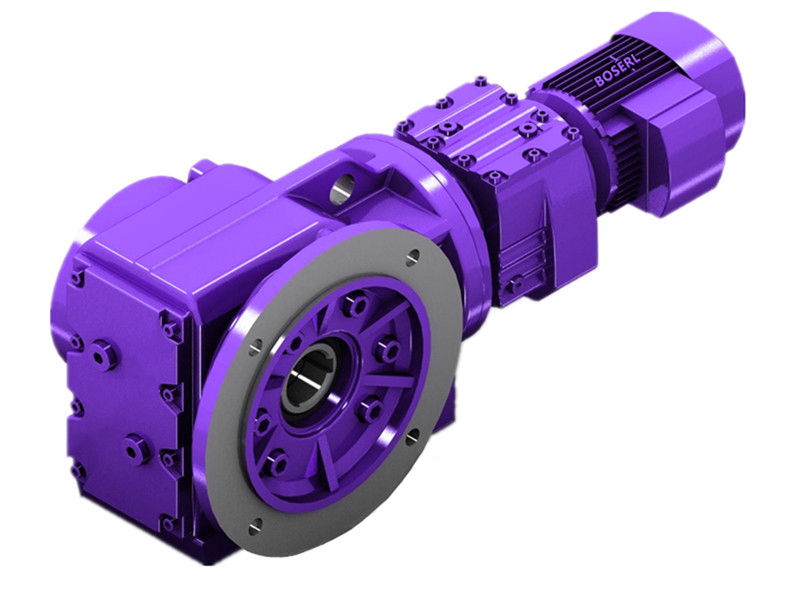

There's also the possibility that man-made manipulations are worseHorizontal reducerThey are not sufficiently structured and well understood (especially by new manipulators) and easily cause problems due to manipulation errors, leading to mechanical and safety accidents. Of course, although oil spills from thereducing machines in the K series are more common and difficult to cure, the introduction of preventive measures has largely helped to control the oil spills from thereducing machines, prolong their useful life and ensure that the equipment produced does not run badly. The K series ofreducing machines are also affected by design factors: Service Actionor; motor input-referral Input Speed; gear selection for Gear Matherial; gear processing/installation error;reducing lubricating oil (slubber) selection;reservation frequency; constant temperature of thereducing machine operating environment;reducing hours; andreducing machine load factor parameters. The above-mentioned topics must be more than just the above, and much more needs to be determined on the basis of the facts, whether the response of the client to our K-series slowdown is due to aging reasons leading to a decrease in production efficiency, whether or not the minor answer is here, because our BOSERL deceleration is a commitment of two years of warranty, with a useful life of up to 15 years, unless others are responsible for the factors rather than maintenance, leading to early aging of the slowdown. Too much gas can lead toMotor-gear reducerin the course of its operation, the oil tanks were heavily disturbed and lubricated oil was splattered in the aircraft, and if there was too much refuelling, a large amount of lubricated oil was stored in the axle seals, patches, etc., resulting in leakage. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Slower is inefficient