Analysis of the causes of the k-series slowing-off axis

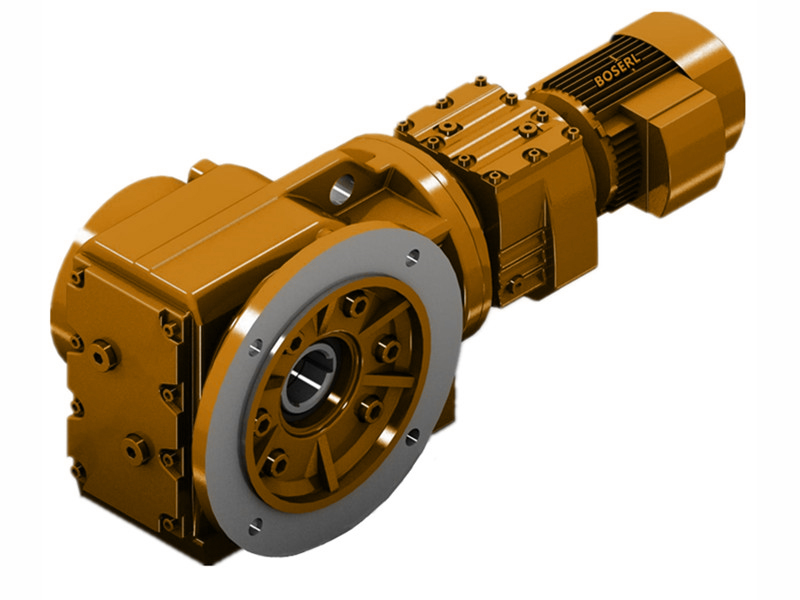

Analysis of the causes of the break-in of the k-series decelerator. The main event today is the k-series decelerator, which focuses mainly on the subject of break-axis, and why such a failure occurred. there'll be a lot of impurities in the k97reducing machine, some of which would be easily created if they were granular impurities that would cause the formation of rodsTurn frequency brakes slowing downThe internal damage is severe, and when it is severe, it also results in a brake axis. This should occur by replacing or modifying the design of the brake. When the power axis is different from theaxis of thereducing machine, the k-seriesreducing vehicle input axis increases the direction load, increases the curves on the axis, and breaks the axis in the long run. Three reasons are more common in the k-series brake axis: theaxis design is not sufficiently robust, theaxis are different, theaxis are too impurities for thereducing machine, and the design strength of the high-axis for the k-series is not so strong as to occur on the shoulder of the axis, where there is a transiting round corner, where there is a high risk of fatigue and damage, such as a small round-anger, which would cause the parabolic gear-reducing machine to break the axis in a relatively short period of time. The cut-off post-axis is usually relatively flat. When the error is greater than the heart, the diameter increases the local temperature of the engine ' s output axis, and its metal structure continues to be destroyed, which will eventually result in the engine ' s output axis being broken by local fatigue. And when you're in different hearts, the engine's output axis has to come from.Motor-gear reducerEnter the real trajectories (tangulars)。

The gearbox cleaners use the original discharge system of the gearbox and filtered lubricant to clean the gearbox, do not change any hardware initiative in the gearbox, do not add any detergent, ensure the safe operation of the gearbox and extend its useful life. DecreasedGearbox motorBreak-axis happens. The effect of this rudder will force the engine's output axis to bend, and the direction of the bend will change with the output axis rolling. In most cases, the axle does not break because of the material of the axle is 45 steel, the axle is thick and the stress is better, so the axle does not normally break. It is certainly not just the above-mentioned cause of the k-series brakes, but ultimately, if our maintenance measures were in place, our boserl brakes would not have been such a serious accident, because we, the boserl brakes, have been assured, for life, with a useful life of 7-18 years. They should be carefully repositioned for installation and maintenance to ensure that the two axes converge. it's called "k" by nameGeared motorThe axes are split into two, and when co-centres are guaranteed between the driver ' s motor and the Motor-gear reducer, the engine ' s output axis is subject only to rolling power (twirl) and will operate smoothly without pulse. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Reason for the brakes