K-serial angular speed retrenching 90. 5

A 90. 5 retrospect for the output of the k-series moving hornbox. A low-temperature high- centrifuge can contribute to the accuracy of temperature control while the progressive centrifuge operates and is energy-efficient and environmentally sound and has a good centrifugal effect. operating silo tops with organic covers, operating silos, with a cooling section inside the silos, which include a cooling-out pyramid, constructed into the cavity room in the middle of the base of the puddle, installed in the chamber interior and driven towards the top of the bodySecond-stage brakesIt has a cavity lid to support the motor at the bottom of the cavity, with a threaded link between the outer rim of the cavity and the cavity. A lid is placed at the starting point of the centrifuge, a dry refrigerator is secured on the lid, a temperature sensor is installed at the base of the dry refrigerator with an electrical connection control system, a variable frequency thermal wind machine is installed in the operating warehouse, an inductive airpipe is installed on the transformer windmill, a dry fridge is entered into the cavity room, and a reflower is connected between the cavity chamber and the transformer winder. (c) the control system referred to in the fhw power connection. In the user's selection process, his request was for an output of 90. 5 rotations after the use of the k-series roller engine, so what would be the appropriate configuration of the power and ther? In the absence of further parameters, look at some details of the user's equipment. (b) a system of electrical connection control of the variable-frequency thermal wind machine. However, there are no detailed parameters required in these cases, so let's look at some of the detailed configurations on the selected sample. this is a time for the introduction of the fm and k seriesMove the corner boxForreducing machines to meet user needs, the options are k67, k57, k37。

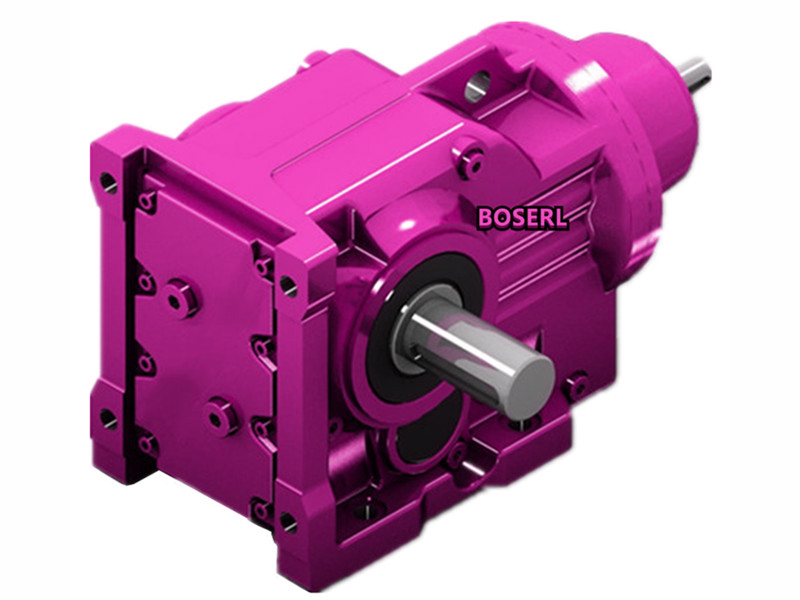

During the separation of some mixed substances, it may sometimes be necessary to separate the corresponding substance by centrifugal manipulation. This is used by the user's centrifugeAn umbrella gear-reducing machineSome things. In a recent user request, his request was to use an electric device with areducing machine as a drive transfer device for his centrifuge. The base of the plume is connected to a “y”-shaped pipeline, the top two ports of the plume are connected to two gas holes, respectively, and the bottom of the plume is extended beyond the airframe, with an electromagnetic valve at the bottom of the plume. The drive-axis jackets that drive the K-series drive angular accelerator sets up a segregated liquid. But in the user's use requirements, his request is to use an electric power to fit the K-series drive-boxdischarger and then reach an output of 90.5. How many electrics andreducing models should be selected under such a requirement? Let's take a look today at the selection of the centrifuge K seriesbox. The top of the engine that drives the K-rolling hornbox is secured by a centrifuge, with an average of leak holes on the surface of the centrifuge, a hemispheric-shaped filtration network on the outside of the centrifuge, a filtration net to the top of the body, a centrifuge to be contained in the filtration net, a drive engine to the K-roller to the lower end of the filtration network, and a cavity at the bottom of the cavity on both sides of the cavity. The top of the motorreducing machine is secured with centrifuges, with an average of leaks on the surface of the centrifuge, a hemispheric-shaped filter on the outside of the centrifuge, a filtration net to the top of the body, a centrifuge to be contained in a filter, and a driver to service the engineGeared motorThe driving axis runs through the bottom of the filtration net and the base of the plume is on both sides of the said cavity chamber. Centrifugal is achieved through a rapid mechanical rotation for the purpose of separation. The high- centrifuge ' s silo consists of a penthouse-shaped cavity, constructed of a cavity chamber in the middle of the base of the cavity and installed in a motor-reducing machine in the direction of the top of the body of the cavity. The combination of these three models and the variable frequency modulation power sets allows for the needs of users to be met. detailed parameter sizes can be consulted with boserl selected technical staff or a downscaling sample。

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The speed-rejector output is going 90.5