Operation of an oil-supply system for a recoiler and an electric generator

(b) operation of an oil-supply system for a recoiler and an electric generator. In particular, welding steel pipes should be treated for acid wash or spray. Inaccurate tests would result in serious accidents if the energy collectors of the r-reducing electrostatic hydraulic system did not agree to any machine processing and to any work on electric arc or fibre welding. Sanitation should be cleaned of the surrounding area before any screwdrivers in the r series slow down. because it's all dirtyPower-drivenreducing machineHydraulic equipment with electric power can cause devastating damage and should therefore be considered clean when testing hydraulic equipment. Note: damaged steel and hoses must be replaced immediately. Only sutureless steel pipes manufactured in the r series ofreducing machines are available. When a recoiler is installed with a hydraulic set of electrons, the location, ambient temperature, working voltage etc. Shall be determined (relevant equipment information is also available). the energy receptacle is a pressure container, and the working pressure set of the recoilers and electrics should be adjusted in a safe and local manner according to the working conditions on the site。

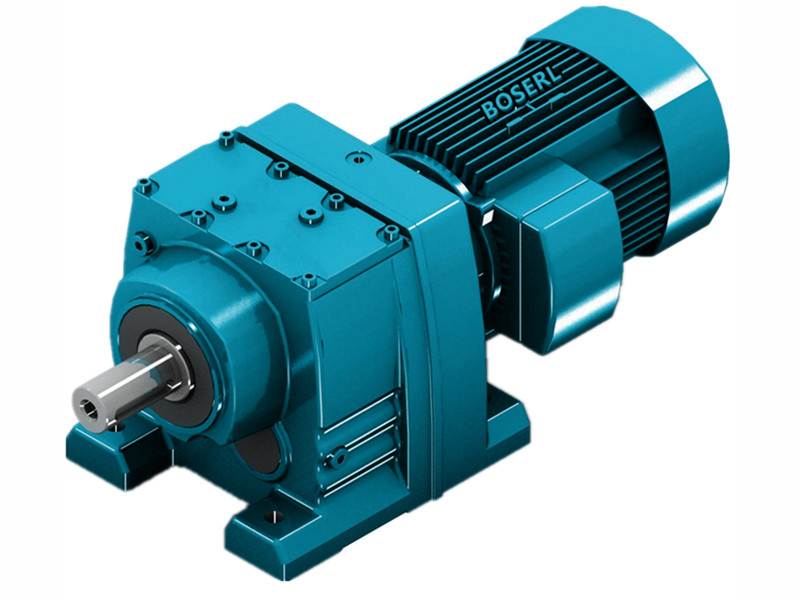

This means that the assembly surface of the r-seriesreducing device should be proportionately flat, and that its fixed bolts should be balanced against the given twist. the pipeline should be removed before it is installedMotor gearedAnd a set of all the dirty things, rust, sand and iron crumbs. In order to prevent the measuring of the slug from dying, the installation of control equipment should ensure that it does not withstand additional stress. Before any work is performed on hydraulic equipment (including energy collectors), the oil pressure of the discharge system (e.g. testing, connecting pressure sheets, etc.) is required. The system should first be discharged, the pump should be stopped and the pressure on the energy receptacle should be released. When choosing to connect a recoiler to the electric generator's set of pipelines, hoses and screwdrivers/Frand, it is important to check whether their resistance properties match the pressure of the system (e.g., barrel thickness, materials). No hair-weave can be used to clean the pipeline. While some generic manipulation and maintenance instructions for hydraulic systems can provide valuable information for the use and maintenance of oil-supply systems, special descriptions are required。

In order to ensure the reliability of an oil supply system for the recoilers and generators, it is necessary to follow the manipulation and maintenance instructions provided by the manufacturers of the boserl oil supply systems and hydraulic components. when varnishing a system device with a jet gun or brush on a pv and an electric machine, especially in the r seriesGeared motorFibrous paints, which shall be protected by means of objects covering all flex seals and scrolling bearings. All openings are sealed with a protective cap to prevent the dirty material from entering the hydraulic system. Installation of lubricant pipeline works: it is not normally necessary to install or adjust the installed plumbing works at the workshop, which can be done only after consultation with boserl. The screws don't hold on to the drill. Pipes should be fitted to avoid external stress. Common description of the operation of a hydraulic device set of a recoiler and an electric device: for safety reasons, when the hydraulic system is in a state of pressure, there is no agreement to loosen the mains, screws and hydraulic components. The test of the hydraulic system ' s collectors can only be performed by a staff member designated by the renk or part of the after-sale service of the hydraulic system. The connection between the recoiler and the electric tube set can only be made from a screwdriver or a french joint provided by the manufacturer and the corresponding seal. refusal to use sealed materials such as grinding ropes and fillings, as they would causeHorizontal reducerSystem contamination and equipment damage. Oil tanks should never be washed with a rag and filters should be used to refuel the system. You can find these special descriptions in notes on oil supply systems andreducing machines, in technical information on R-reducing power supply systems and in general safety information. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Operation of a fuel supply system for speed-reducing machines and electric generators