Emplacement manual for umbrella gear-reducing machines

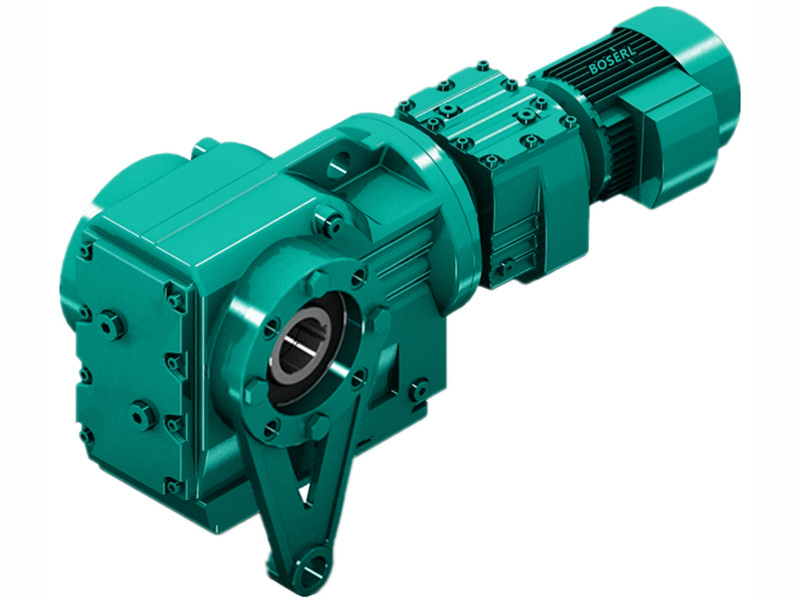

Handbook on the installation of an umbrella gear-reducing machine. When the base bolts are tightened, a bubble-standard instrument shall be used to conduct inspections on the basis of the points on the watch of the gear box. An umbrella gear-reducing machine plus an electric generator is used for the industrial installation of gears or other equipment from machines, k-reducing machines. safety precautions are observed when the department or equipment in the entire k-seriesreducing unit is manipulated。Stand-by gear brakesThe basic rules for the charger require the precise installation of an umbrella gear-retarder plus the turbo-exposure, whether or not the gear exceeds the gear pair. The range k shall normally not exceed 0. 15 to 0. 20 mm. The officer in charge of the security determination shall ensure that: the installation of the equipment and machinery shall be controlled by professional staff; the officer in charge shall be strictly responsible for the use and compliance with the determination of the curator and other technical requirements attached to the product; it shall be irrelevant that the lay officer shall not be allowed to manipulate the installation and the machine; the professional employee shall mean the employee having his or her profession, the experience and instructions of the operation and the knowledge of the curator having the rules, the relevant scales, the classification of the accident prevention. umbrella gearGeared motorThe position of the turret vessel on the ground will affect the load curve of the gear. They are also assigned to carry out the necessary manoeuvres and to become familiar with and prevent dangerous accidents. Therefore, the cortex must exceed at least 50% of the length of the cortex。

Turn the gears in a normal way for a few laps。Motor-gear reducerThe agreed common value for the two measures of error is 0.02 mm/m of one/two tics (please refer to the tic value of bubble calibration 1 and 0.04 mm/m of 1 tic). In case of an umbrella gear-retarder with a load-free motor, KlingeInberg's teeth must be exposed as shown in the figure below. Gear contact can wash it out. Professional staff should also be informed about first aid and the central local first aid. Misuse, inaccuracies and a lack of attention can lead to machine damage and even endanger staff health. Tests of the gear surface of the K-seriesreducing machine, which are marked on the side side of the tooth with a small and light marking compound. Otherwise, please strengthen the gear contact face. As a result, in the absence of load, a less powerful carving surface is required and the smaller carving surface is very close to the larger end of the gear. An accurate dent exposure can be achieved when the turbo-level instrument on both sides of the turbo-delayer plus the turbo-container is equal. Note that small contact with the K-seriesreducing machine reduces operational discomfort but lowers the noise. WhenRight-angle shaft reducer motorWhen the charger uses a different scale, etc., it is necessary to calculate the discrepancy to maintain it. In non-loading, calibrate the cone gear-reducing machine plus the electric machine contact side, on the side of the “front” (v) . . . . the side of the dent in the middle, on the side of the “reverse” side (r): the K-series gear contact is close to the large end, the gear-reducing side is not allowed to interact with the small end, the staggering of the wheel-exposure is followed by an increase in the load, the mistyping of the wheel-axis is exacerbated and the gear-exposure moves towards the small end of the cone. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Emplacement manual for umbrella gear-reducing machines