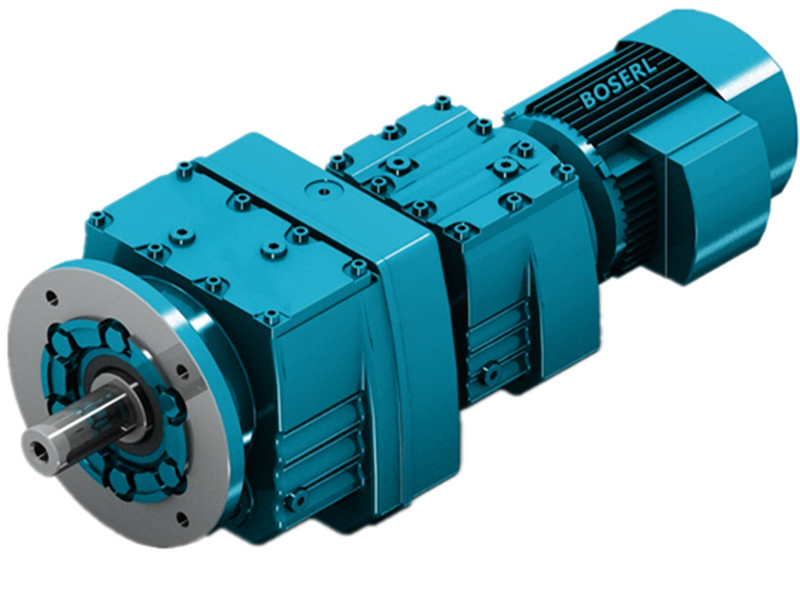

Open gear speed-retarder and electric power set of hydraulics

A stand-by gear-retarder and an electric power unit of hydraulic equipment are operational. Experience has shown that most impurities are separated within hours of work. Make sure they're clean with a set of lubricating gear and power! The caps of the containers of the oil stored are cleaned before they are opened to check if the tanks are clean and, if so, if they are to be cleaned; and to check for water intrusion of the lubricants. OpenMotor gearedIt's a pipe valve with the electric. A fixed set of gas with a standing gear reductioner and an electric generator is used to inflate the energy collector (if fitted) at a predefined pressure and only nitrogen. An eye check of damage and contamination during transport of a standing gear-reducing and electrical system. (b) ventilation; exhausting of a set of gear and power sets may occur at the height of the user line. Accurate lubricating oils (especially viscosity) are an essential prerequisite for ensuring the unprovoked operation of a fixed gear-reducing and electric system. When the oil in the tank is free of bubbles, the system operates without crawling and abnormal noise, indicating that the exhaust process has been completed. The plant shall prepare a hard copy of the record, record the working hours of a solid gear-reducing machine and an electric machine as scheduled, lubricating oil temperature, oil pressure, abnormal noise and the replacement cycle of refuelling and filters. The commissioning component of the hydraulic system was completed by the boserl plant, but often at a later site. This process cannot provide general technical guidance. whenGear-retarding machineA set of fully operational hours followed by monitored working temperatures. Connect to cool water. Check the level of oil and fill it if the vent is required. Cleaning or replacing filters. However, these maintenances are necessary to ensure the unprovoked functioning of the system, and experience has shown that most of the system malfunctions and damage are caused by impurities in the oil, inaccurate maintenance and the misuse of the oil. A set of motors with a high gear and a motor: a dot, check the switch!

regulating valves: valves are usually set at the pressure value required for work. the vertical gear-reducing machines and hydraulic elements of an electric power system are designed for long-term unprovoked operation, and they require only a small amount of maintenance. (b) a set of turbo-barrel and electrics for lubricating oils: filters are to be added to the lubricant and filters are to be filtered by at least 25 mm to refuel the pumps. use hydraulic system withGeared motorConnect and apply fluid for a longer period of brushing after the installation of the oil and hoses. Following a check of the loads of the connected equipment, electrical installation of electrical power and control equipment was carried out. The scope and cycle of a set of inspections and maintenance of a standing gear and power sets are usually specified in the form of the type of brake machine used by the system. In all cases of refuelling, the filters or filtration cores in the filters at the point of the annotation are removed. (b) a set of vertical gearreducing machines and electric machines to install and assemble hydraulic systems and hydraulic parts. Special attention should be paid to the following during the commissioning of a set of flat gears and motors: fixed plants are often provided with pre-equipped flat gears and a hydraulic system for electric machines. Oil spills are treated, and in most cases they can be eliminated by a tight screwdriver. The oil tank was added with the specified lubricants. A back-to-back gear reduction machine regulates various valves with an electric generator and moves to a reduction machine as provided by boserl. security measures: to ensureStand-by gear brakesa complete set of devices with electric power can be safely activated and should not be manned in hazardous areas. all valves are opened according to the procedure, and the system is repressured and depressed several times, slowly increasing the load. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-retarding and electric power set of hydraulics operational