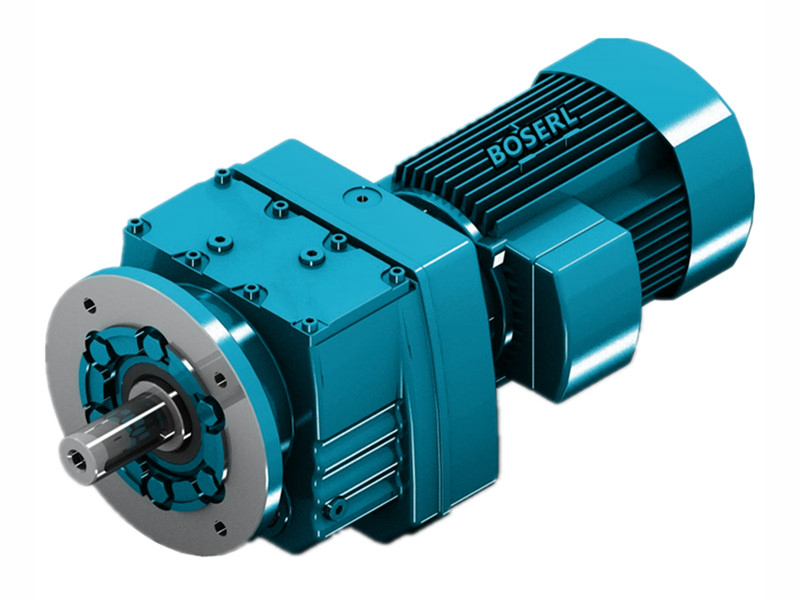

A stand-by speed-retarder and an electric generator to monitor low-pressure lubricating pipe lines

(c) A stand-byreducing machine and an electric generator to monitor low-pressure lubrication cycling lines. During the automated operation, the locked valve limit switch is used to signal the opening of the pump. To monitor pollutionSlow downAn optical and electronic pollution display was also installed with a filter set of electric appliances. The continuous progress of the pressure is evidence of the progress of the rf seriesreducing filters (see the maintenance section for cleaning). The rf seriesreducing filters can be transposed simultaneously during the time of installation. Filter elements that have been discarded as a result of contamination should be accurately disposed of. A set of two-fold filters, such as a stand-by decelerator and an electric generator, would have to be diverted, and the contaminated rf series would have to be removed and cleaned. In the tube line, the pressure is caused by the loss of pressure between the filter and the cooler. The rf seriesreducing oil-routing system is being manipulated to increase contamination levels, and the indicator shows an increasing number of red tics. When the alarm signal is raised, immediate personnel are required to look for the reason for the general pressure alarm and, at the same time, to remove the alarm so as to avoid the entry of the motor. If the precise filter component has been replaced in accordance with the rules of manipulation, the cleaning distance should be extended accordingly. please pay attention, whenMotor gearedWhen it's cold with the electrons, the pressure is higher. Prior to this, lock valves that are likely to be installed in pipes must be closed. Note that the cleaned filter elements should be re-installed as soon as possible to ensure the correct manipulation of the entire system。

A set of pressure sheets for the stand-down and power sets shows pressure upstream for the downstream of the lubricant pump and the lubricant filter, while the pressure table indicates pressure downstream for the oil cooler at the export point of the system. During the auto-manipulation, the oil circuit system can only be connected if the locked valve is fully open. completely replaces the entire filter component. The range of pressures at different temperatures is documented in the technical data table. WhenVertical reducerUpon reaching a specific set of pressure differentials with the electric power (see the technical data table for specified values), the red scale will account for 70 per cent of the monitor (the monitor is marked), while the electronic pollution indicator will send an alarm signal. If the rf seriesreducing filter is clean, then the optical indicator shows the blue scale. In the rf seriesreducing gear gears, the oil pressure downstream of the oil cooler at the rf seriesreducing system entry point is monitored by two pressure switches: when a particular adjustable pressure is reached, a standingreducing and electric pressure set will send a warning signal; and when the pressure drops to a low value (for the reconciliation values, see the technical data table), the pressure switch will enter the molars of the suspense. please activate the pressure-reimbursing valves and dismantle them to the rf series, in accordance with the guidance of a filtration plant with a stand-byretarderGeared motorThe filtration tank's little trachea. Therefore, depending on the level of RF-seriesreducing machine contamination, we recommend that several clean-up procedures be completed. Usually, there will be some impurities left after a stand-byreducing machine has been washed with an electrical filter component, so the cleaning distance will become shorter and shorter. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A set of slow-down machines to monitor low-pressure lubricating tubes