Parallel axle gear-reducing and electric power sets of failure diagnostics

A parallel axle gear decelerator and electric power set of failure diagnostics. When the f seriesreducing machines are unable to reach their rated turn-off rate, which may be due to the use of abnormality, the low voltage of the end-of-wire power units (resulting from line-downs), the high start-up load of the f seriesreducing machines is such that the rotor bar is broken or the rotor is loose, and the back circuit is broken, the treatment is to ask the supplier for the exact type of product, to use a higher parallel axle-reducing or transformer end or lower load, to check the connection, to check the specification of the conductor, to check whether the load-f series is normal at the start, to find if there are cracks around the rotor ring, to use new rotors, repairs are usually only temporary, and to use test devices to identify malfunctions and repair them. on the parallel axisGeared motorUnder the condition of unmounted operation, the electrics have had heat problems, the vents of the overloading racks or shelves have been blocked and the normal venting of the electrics has been prevented, the electrics have been disconnected, the electrics have been disconnected, the loops have been closed, the end voltage is unbalanced, the vents have been opened and there has been a continuous flow of air out of the electrics to check and ensure that all the circuits are well connected, the location of the f-series decelerators is located and repaired, faulty fuses are checked, the head and transformers are checked。

The parallel axle gears are cut off from one set of power units after failure, the use of faulty, overloading, low-pressure, short circuits is checked, the type or size is changed, the manufacturer is consulted, the load is reduced to ensure that the corresponding voltage values on the signboard are reached, the fuses on the interface are closed, overloaded relays are checked, the beams and buttons are checked, the fuses and the connections to the control devices are loose, and the power stoppage is the direct cause of the power outage. check for loose circuit links and ensure that all control contact points of the f-seriesreducing machines are closed, check for the electrical and moving devices to be rolling as they please, check for bearings and their lubrication, in the form of fuses meltingAn umbrella gear-reducing machineA set of electrons must be rewired to remove the bell-shaped endboard and locate it with a test light to find a broken bar or terminal ring to lower the load. the parallel axle gear reductioner and electric power sets were too long or the currents were misdirected because of overloading, low voltage during start-up, and low voltage applied to mouse cage transfer defects, at which point the f series was to lower loads, check for high resistance, use of a line of suitable specifications, replacement with a new rotor, contact the power company with the progressive power voltage value。

There are many reasons why parallel axle gears and electric sets cannot start:Induction motorThe fuse melts, overloading, electrical anomalies, electrical anomalies, circuitic abnormalities, circuitic or control switches are in a state of breakage, mechanical malfunctions, fixed short circuits, poor wiring connection, rotor-out defects, electric overloading, at which point it is possible to replace them with a fuse of precise type and nominal value, to check and repeat the overloading of the starter, to see whether the f-seriesreducing power supply is in line with the emitter's placard parameters and load factor, and to indicate it by humming (when the switch is closed). there are many reasons for electric vibrations, and parallel axle-reducing machines are being found in error, staggered, inter-axis imbalanced, disequilibrium from kinetic equipment, faulty bearings from the axle, non-lines from the bearings, motion of the balance, conflicting (half-full keys) between the revolving f series of brakes and the balancing of the joint axle, multi-phase motors operating in a single phase, too wide a gap between the axesGearbocre-profiling, strengthening of the substrates, balancing of the joints, re-balancing of the moving equipment, correct alignment of the replacement bearings, re-balancing of the electrics, re-balancing of the joints or the electrics, and checking for the presence of fault-fixing bearings or for the addition of plugs. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

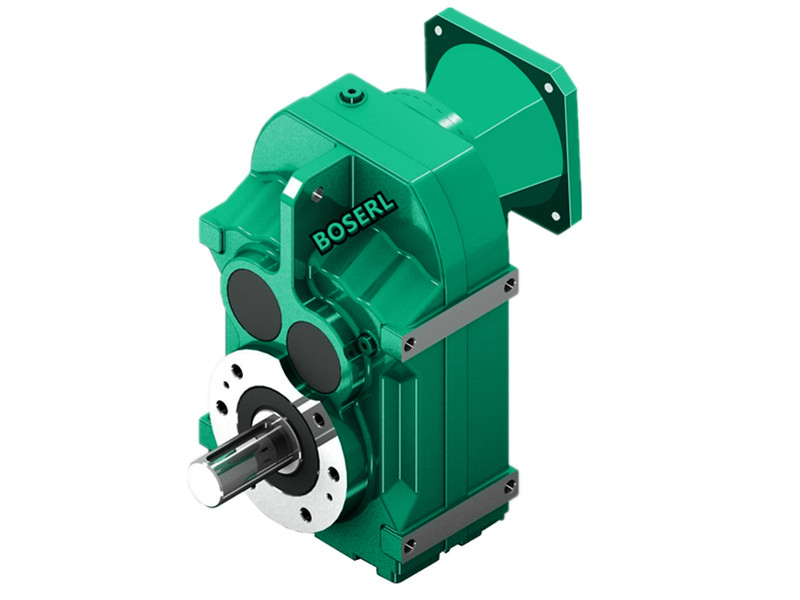

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The speed-reducing machine and the electric power set of failures