The failure and handling of the turbostats

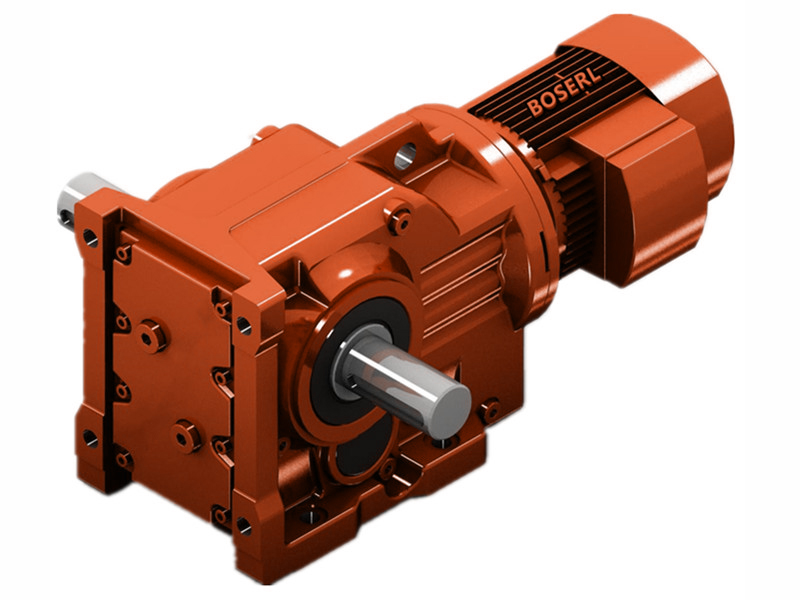

The failure and treatment of the turbostat plant. 1. Straight flow: In order for excess lubricating oil to be dumped by gear on the bearings to remain uninvented at the axle seals, it is necessary that the excess lubricating oil flow back to the oil tank in a fixed direction, i.e., to keep it flowing。Big-rate slow-down machineDespite the presence of air-traffic caps, the vents are too small to be easily clogged with coal powder and oil, and each refuelling must open the lids, increasing the probability of a secondary spill and leaking where they are. High-molecular materials can manage leakage on site, and the material has a strong sticky, oil-resistant and 350% stretch to overcome itAn umbrella gear deceleratorThe impact of vibrations is well settled for the businessAn umbrella gear deceleratorLeakage。An umbrella gear decelerator(b) Axes chamber wear, which includes a shell bearing box, a hole bearing room in the box, and axle bearing room in the gearbox;An umbrella gear decelerator(b) Axes of gears, with the main wear and tear in the axis, the key slot, etc.;An umbrella gear deceleratorAxle bearing wear; umbrellaGeared motorCombine seepage. Contemporary Westerners use more of the repair methods of high-molecular composites for the above-mentioned topics, which have a combination of super-strength and excellent resistance。

the traditional solution to the subject of wear and tear is welding or post-plating machine restoration, both of which have a downside: thermal stress from the high temperature of welding cannot be completely eliminated and can cause material damage, causing the parts to bend or break; the plating of electric brushes is limited by the thickness of the coating, is easily stripped, and both methods are metal-fixing, and cannot alter the “hard-to-hard” co-operation, which, with the combined effects of the forces, still causes further wear and tear. the detailed approach was to open a refuelling tank in the middle of the lower side of the axle bearing, tilting it inside the engine, while also opening a gap at the straight end of the cover, which was the reverse of the retrenchment, so that the excess lubricating oil was lost and the retrenchment flowed back to the tank. to this end, a gas-cap was produced and the original thin lids were changed to 6 mm thick, and the gas-caps were welded on the lids with an air-traffic diameter of 6 mm, which allowed air to flow, achieved average pressure and refuelled from the cups without having to open the lids to reduce the oil spill. not onlyStand-by gear brakesAnyAn umbrella gear deceleratorWe can't afford to wait until we've lost control of itAn umbrella gear deceleratorLike the hard-working boys on the field, if you don't keep it well, you get sick like Sun Yang and lose the game, we'll finish the week by day。

An umbrella gear deceleratorOil spills are something that cannot be underestimated, and we can deal with them in the following way: for the topic of leakage, traditional methods need to be dismantled and openedAn umbrella gear deceleratorSubsequently, the replacement of the seal pads or the coating of the seals not only takes time and effort, but also makes it difficult to ensure the effect of the seals, which will be leaked again in operation. Because..Right-angle shaft reducer motorThe main types of malfunctions are: the application of high-molecular material for repair, which is free from the unreserved weld-heater stress, and the unrestricted thickness of the recovery machine, while the metal material in the product is not subject to a concession, absorbs the shock of the equipment, avoids the possibility of further wear and tear, and significantly prolongs the useful life of the parts of the equipment, saves the enterprise a large amount of shut-down time and creates significant economic value. 2. Improvement of air-traffic caps and examination of hole lids:An umbrella gear deceleratorthe main reason for the oil spill is the fact that the internal pressure is greater than the external atmospheric pressure, which can be prevented if the idea is to balance the internal and external pressure. for some of the larger bearings, it is impossible to solve them on-site and rely on external assistance for rehabilitation. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The failure and handling of the turbostats