How can an umbrella gear-retarder maker be repaired with wear and tear?

How can an umbrella gear-reducing manufacturer repair it? Why would boserl’s little editor say that? Whether we live in a living, it is still the machine that we use in the industry, and with a long time, it causes frictions and damage, and it is a very frequent subject that makes customers feel very upset. The subject of wear and tear, the solution of a business or a manufacturer so great that our users can weld or plating and then process and repair, but both do not cure the symptoms. because it's trueSpiral cone gear deceleratorIf welding is done, the heat of welding is knownAn umbrella gear deceleratorAnd the material damage causedAn umbrella gear deceleratorThe internal parts are curved or fractured. we're boserlAn umbrella gear deceleratorIt's more modern and sophisticated manufacturing technology, boserlAn umbrella gear deceleratorEachAn umbrella gear deceleratorBoth have the characteristics of grinding and non-fragmentation, and the reputation within the industry is very good. Since it's not working, it's workingAn umbrella gear deceleratorFriends will choose to plating, which will be limited by the thickness of the coating, which will be easily removed, and both of these methods will be metal repair, which will not change the "hard touch" that will still lead to fall when the metals are mixed up, so the boserl sub-editor recommends that you do not use welding or plating to repair the worn-outSnailreducing machine。

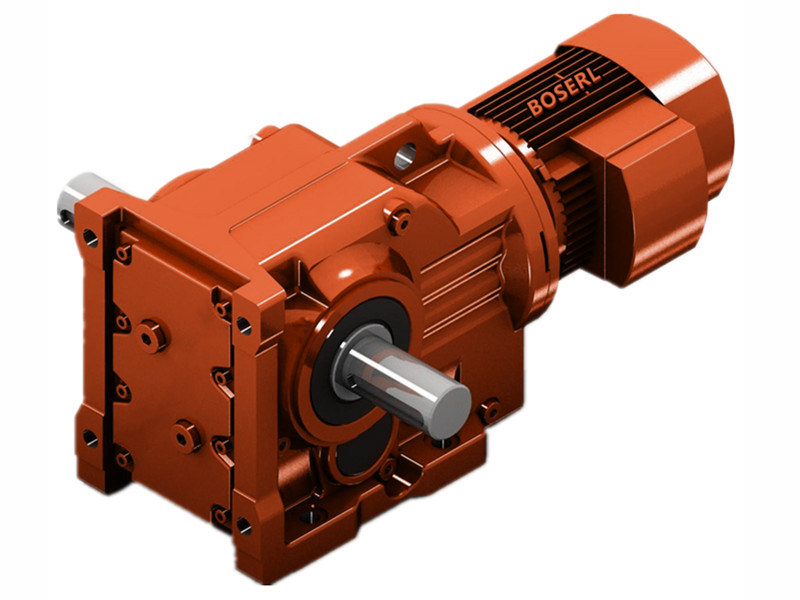

An umbrella gear-reducing machineThe plant is subject to extensive wear and tear during long-term transmission, and the parts and components of wear and tear include a shell bearing box, a hole bearing room in the box, and axle bearing room in the gearbox. does anyone think that boserl's method is very practicalAn umbrella gear deceleratorWearing friends can fix this by using the above-mentioned methods, and if they don't have friends, they can keep them in case of need! High-molecular materials can also manage leakages on site, and the materials have a strong sticky, oil-resistant and 350% stretches to overcome themAn umbrella gear deceleratorThe impact of vibrations is well settled for the businessAn umbrella gear deceleratorLeakage. Boserl sub-editories recommend that high-molecular material recovery be avoided by demanufacturing the process of the machine, which has neither the residual welding stress effect nor the thickness of the restoration, while the metal material in the product is not subject to any concession, absorbs the shock of the equipment, avoids the possibility of further wear and tearing, and significantly prolongs the useful life of the equipment components, saves the enterprise considerable shut-off time and creates significant economic value. of course, for some of the larger bearings they useAn umbrella gear deceleratorIf the wear and tear cannot be solved on the spot more often, then what should we do if we rely on the two inaccuracies I have described above? Contemporary Westerners have suggested, in response to the above topics, the use of high-molecular composites, more of which have combined power with super-strength, excellent resistance. But we're in other mechanical industriesAn umbrella gear deceleratorWhat about the wear and tear? today, boserl's editor shows you in the mechanical industryGeared motorProducerIf there are general conditions and solutions in the long run。

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The umbrella gear-reducing machine was worn out and repaired